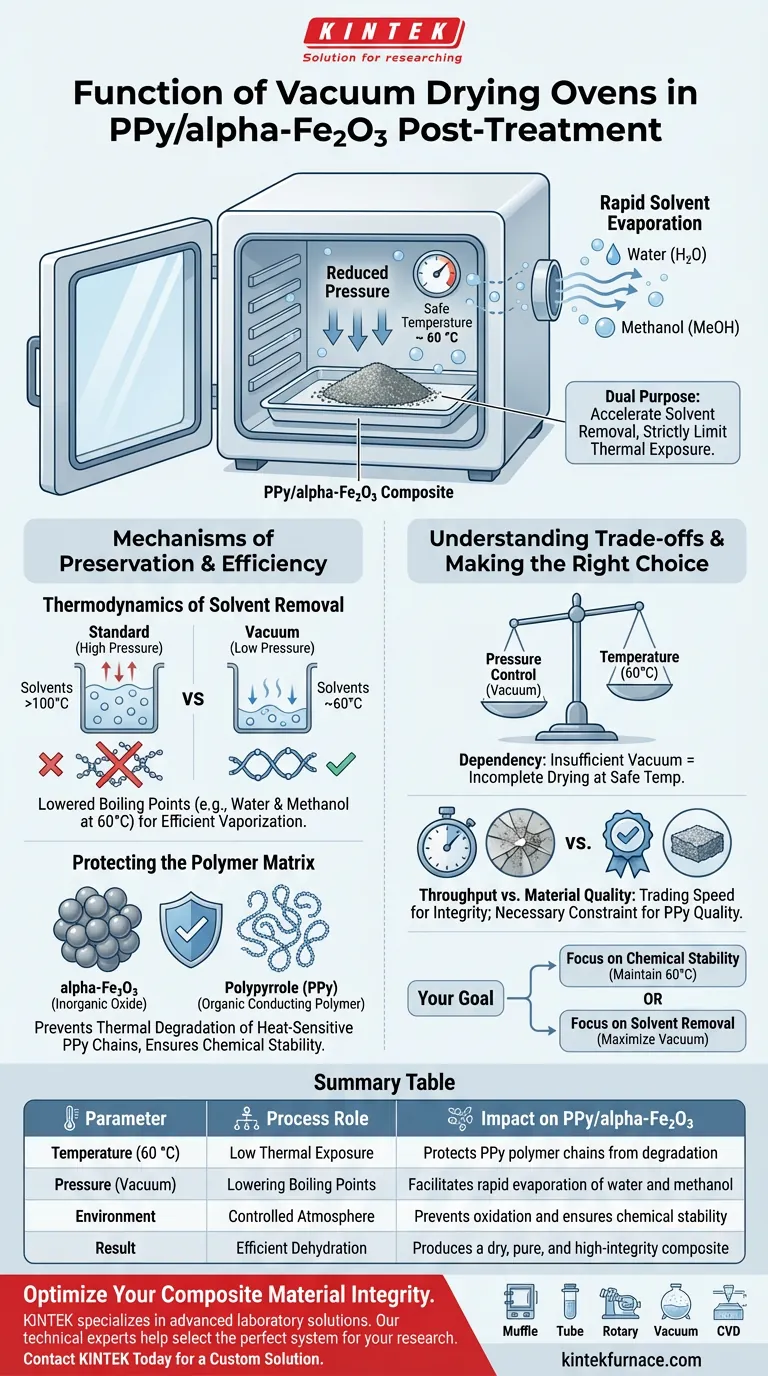

The vacuum drying oven serves a dual purpose in this specific post-treatment: accelerating solvent removal while strictly limiting thermal exposure. By operating at reduced pressures, the oven lowers the boiling point of liquids, allowing for the rapid dehydration of washed precipitates and the removal of residual solvents like methanol at a safe temperature of approximately 60 °C. This specific environment is engineered to protect the heat-sensitive polypyrrole (PPy) polymer chains from thermal degradation, ensuring the chemical stability of the final PPy/alpha-Fe2O3 composite.

Core Takeaway The fundamental value of vacuum drying here is decoupling "drying speed" from "high heat." It allows you to aggressively remove moisture and solvents without subjecting the fragile polymer component (PPy) to temperatures that would destroy its molecular structure.

Mechanisms of Preservation and Efficiency

The Thermodynamics of Solvent Removal

The primary challenge in treating PPy/alpha-Fe2O3 is removing persistent solvents—specifically moisture and methanol—without applying destructive heat.

In a standard environment, rapidly evaporating these solvents would require temperatures near or above their boiling points. Vacuum drying alters this thermodynamic landscape. By significantly reducing the ambient pressure, the boiling points of water and methanol drop drastically. This allows them to vaporize efficiently at just 60 °C, a temperature that is thermodynamically active enough to dry the material but kinetically slow enough to prevent damage.

Protecting the Polymer Matrix

The composite material consists of two distinct parts: alpha-Fe2O3 (an inorganic oxide, generally thermally stable) and polypyrrole (an organic conducting polymer).

The PPy component is the limiting factor. Polymers are susceptible to thermal degradation, where high heat causes the polymer chains to break or cross-link explicitly, destroying the material's conductivity and chemical properties. The vacuum oven ensures that the drying process respects the thermal ceiling of the PPy. By keeping the temperature low, the oven maintains the chemical stability of the polymer chains, preserving the integrity of the overall composite.

Understanding the Trade-offs

The Balance of Pressure and Temperature

While vacuum drying offers superior protection for heat-sensitive materials, it introduces a critical dependency on pressure control.

The process relies on a vacuum-tight seal. If the vacuum level fluctuates or is insufficient, the boiling point of the solvents will rise. At the target temperature of 60 °C, an insufficient vacuum will result in incomplete drying, leaving behind residual methanol or moisture. These residues can interfere with the material's performance or lead to degradation over time.

Throughput vs. Material Quality

Vacuum drying is generally a batch process and can be slower than high-temperature continuous conveyor drying used for less sensitive materials.

You are trading processing speed for material integrity. While higher temperatures (e.g., 120 °C) might dry other inorganic slurries faster, applying that logic to PPy/alpha-Fe2O3 would likely result in a brittle, non-conductive, or chemically degraded product. The vacuum oven is a necessary constraint to ensure the quality of the organic component.

Making the Right Choice for Your Goal

When configuring your post-treatment process for PPy/alpha-Fe2O3, consider your specific constraints:

- If your primary focus is Chemical Stability: Prioritize maintaining a steady temperature of 60 °C; exceeding this to speed up drying risks degrading the PPy chains.

- If your primary focus is Solvent Removal Efficiency: Ensure your vacuum pump is calibrated to reach the lowest possible pressure, which maximizes the volatility of methanol and water without requiring additional heat.

Ultimately, the vacuum drying oven acts as a shield, allowing you to achieve a dry, pure composite without sacrificing the delicate polymer structure that gives the material its functionality.

Summary Table:

| Parameter | Process Role | Impact on PPy/alpha-Fe2O3 |

|---|---|---|

| Temperature (60 °C) | Low thermal exposure | Protects PPy polymer chains from degradation |

| Pressure (Vacuum) | Lowering boiling points | Facilitates rapid evaporation of water and methanol |

| Environment | Controlled atmosphere | Prevents oxidation and ensures chemical stability |

| Result | Efficient dehydration | Produces a dry, pure, and high-integrity composite |

Optimize Your Composite Material Integrity

Preserving the delicate structure of PPy/alpha-Fe2O3 requires the precise thermal control that only a high-performance vacuum system can provide. KINTEK specializes in advanced laboratory solutions backed by expert R&D and manufacturing. We offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the unique drying and heat-treatment needs of your lab.

Don’t compromise on material quality—let our technical experts help you select the perfect system for your research.

Contact KINTEK Today for a Custom Solution

Visual Guide

References

- Renjie Wang, Sankui Xu. Polypyrrole/α-Fe2O3 Hybrids for Enhanced Electrochemical Sensing Performance towards Uric Acid. DOI: 10.3390/coatings14020227

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the core advantages of using a microwave sintering furnace? Unlock Precision in Al2O3/TiC Ceramics

- Why is a 1200°C hold required for Ti(C,N)-FeCr sintering? Unlock Superior Material Density

- How are heat treatment furnaces utilized in the automotive industry? Enhance Component Durability and Performance

- What is the role of a high-temperature reaction furnace in flame fusion? Master Alumina Spheroidization

- Why is an industrial-grade drying oven necessary for biomass activation? Ensure Structural Integrity & Yield

- What is the function of a vacuum drying oven in cement testing? Preserve Sample Integrity for XRD/MIP Analysis

- How does optimizing fuel gas mass flow affect the thermal efficiency of an industrial furnace? Maximize Heat Retention

- What is the purpose of using nitrogen cylinders and flowmeters? Ensure Superior Carbon Fiber Recovery