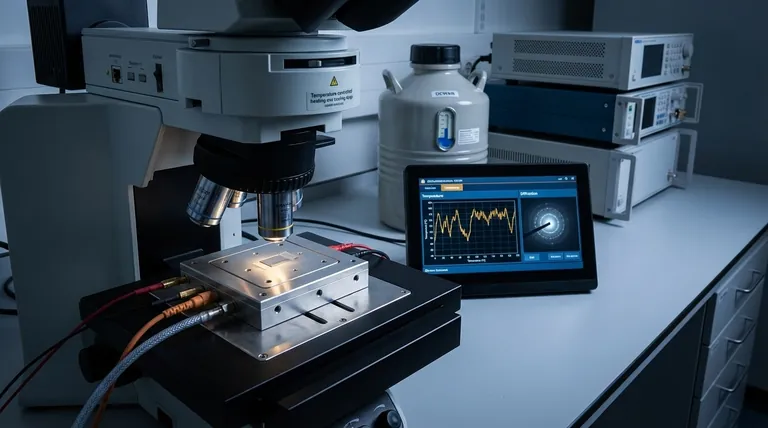

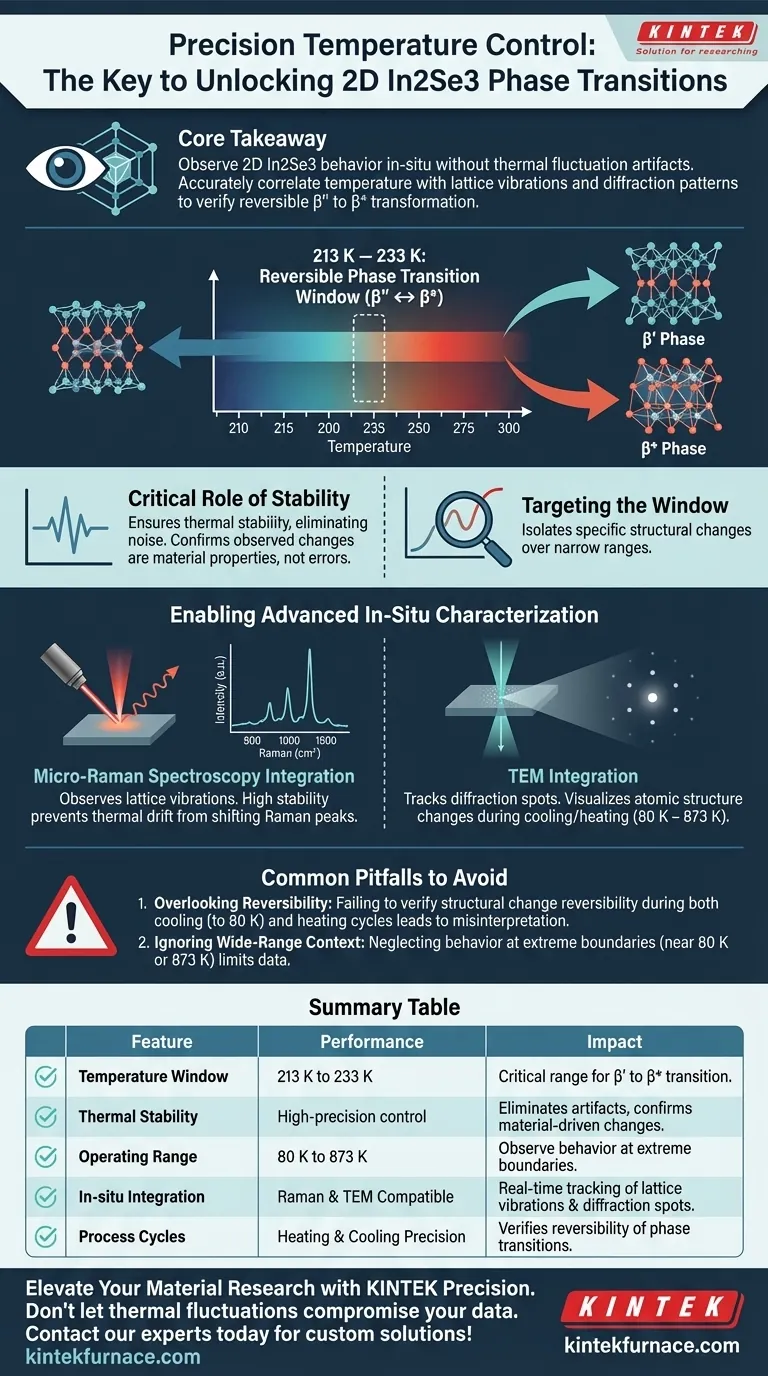

A high-precision Temperature-Controlled Heating and Cooling Stage is critical because it provides the extreme thermal stability necessary to observe subtle, reversible phase transitions in 2D In2Se3. Specifically, it enables the accurate capture of structural changes during the narrow transition window between 213 K and 233 K, which standard equipment may miss or blur.

Core Takeaway To fully understand the properties of 2D In2Se3, you must observe its behavior in-situ without thermal fluctuation artifacts. A high-precision stage allows you to correlate specific temperatures with exact changes in lattice vibrations and diffraction patterns, verifying the reversible transformation from the beta-double-prime ($\beta''$) phase to the beta-star ($\beta^*$) phase.

The Critical Role of Temperature Stability

Targeting the Phase Transition Window

The primary challenge in studying 2D In2Se3 is isolating specific structural changes that occur over narrow temperature ranges.

A reversible phase transition, specifically the $\beta''$ to $\beta^*$ transition, occurs strictly between 213 K and 233 K.

Eliminating Thermal Noise

Without high-precision thermal control, temperature fluctuations can obscure the onset and completion of this transition.

The stage ensures that the sample remains thermally stable, allowing researchers to confirm that observed changes are due to material properties, not experimental error.

Enabling Advanced In-Situ Characterization

Integration with Micro-Raman Spectroscopy

When integrated with Micro-Raman systems, the stage facilitates the observation of lattice vibrations.

High stability is required here because even minor thermal drift can shift Raman peaks, making it impossible to distinguish between a phase change and a temperature artifact.

Integration with Transmission Electron Microscopy (TEM)

For structural analysis, the stage is essential for tracking changes in diffraction spots via TEM.

This allows for the direct visualization of the atomic structure as it shifts during the cooling or heating process across the stage's full range of 80 K to 873 K.

Common Pitfalls to Avoid

Overlooking the "Reversible" Aspect

A common mistake in phase transition studies is failing to verify the reversibility of the structural change.

If the cooling stage cannot maintain precision during both the cooling (down to 80 K) and heating cycles, you may misinterpret the hysteresis or fail to observe the return to the initial state.

Ignoring the Wide-Range Context

While the 213 K to 233 K window is critical for the $\beta''$ to $\beta^*$ transition, neglecting the broader capabilities of the stage limits your data.

Restricting your study only to this narrow window prevents you from observing how the material behaves at extreme boundaries, such as near 873 K or 80 K.

Making the Right Choice for Your Research

To ensure your characterization of 2D In2Se3 is scientifically valid, align your equipment usage with your specific analytical goals.

- If your primary focus is defining phase boundaries: Prioritize the stage's stability in the 213 K to 233 K range to accurately map the $\beta''$ to $\beta^*$ transition.

- If your primary focus is structural dynamics: Leverage the integration with Micro-Raman or TEM to correlate specific lattice vibration shifts with precise temperature points.

Precision in thermal control is not just a feature; it is the prerequisite for validating the reversible nature of 2D material phase transitions.

Summary Table:

| Feature | Performance Requirement | Impact on 2D In2Se3 Research |

|---|---|---|

| Temperature Window | 213 K to 233 K | Critical range for the $\beta''$ to $\beta^*$ reversible transition. |

| Thermal Stability | High-precision control | Eliminates artifacts and confirms changes are material-driven. |

| Operating Range | 80 K to 873 K | Allows observation of material behavior at extreme boundaries. |

| In-situ Integration | Raman & TEM Compatible | Enables real-time tracking of lattice vibrations and diffraction spots. |

| Process Cycles | Heating & Cooling Precision | Essential for verifying the reversibility of phase transitions. |

Elevate Your Material Research with KINTEK Precision

Don't let thermal fluctuations compromise your data. To accurately capture the subtle phase transitions of 2D In2Se3 and other advanced materials, you need hardware that delivers absolute stability.

KINTEK provides industry-leading laboratory solutions backed by expert R&D and manufacturing. Our high-temperature systems and specialized stages are fully customizable to meet your unique experimental needs. Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, we offer the precision required for world-class characterization.

Ready to achieve superior thermal control? Contact our experts today to find your custom solution!

Visual Guide

References

- Dasun P. W. Guruge, Dmitri Golberg. Thermal Phase‐Modulation of Thickness‐Dependent CVD‐Grown 2D In<sub>2</sub>Se<sub>3</sub>. DOI: 10.1002/adfm.202514767

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of magnetron sputtering in N-I-P CsPbBr3 detectors? Optimize Charge Transport & Stability

- Why is a nitrogen protection system necessary for LPF resin synthesis? Ensure Purity in Lab Polymerization

- Why is rapid water quenching necessary for Ce2(Fe, Co)17 alloys? Unlock Peak Magnetocaloric Performance

- What are the temperature advantages of using Cathodic Arc Deposition (CAD)? Boost Film Hardness at Lower Temperatures

- What is the primary function of compacting PVC and metal oxide mixtures? Enhancing Dechlorination Efficiency

- What factors should be considered when selecting a furnace based on material properties? Ensure Optimal Heat Treatment

- Why is staged debinding necessary for perovskite ceramic green bodies? Prevent Cracking with Precision Control

- T6 vs T73 State in AA7050 Alloy: How to Choose the Right Two-Stage Aging Process for Strength and Durability