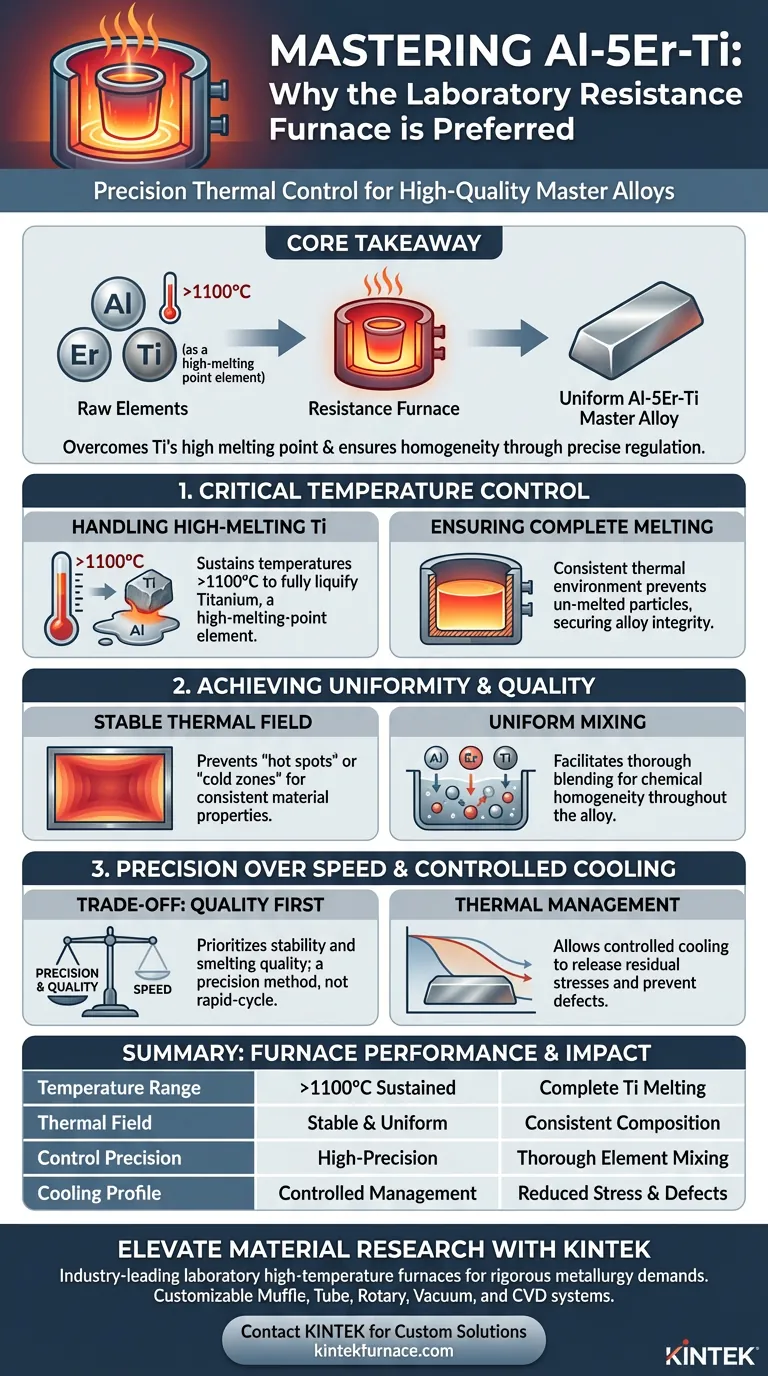

A laboratory resistance furnace is the preferred instrument for preparing Al-5Er-Ti master alloys because it provides a stable, high-temperature environment capable of reaching over 1100°C. This precise thermal control is critical for processing alloys containing high-melting-point elements like Titanium (Ti). It ensures that every component within the master alloy melts completely, resulting in a chemically uniform composition.

Core Takeaway: The preparation of Al-5Er-Ti alloys hinges on overcoming the high melting point of Titanium while maintaining homogeneity. The laboratory resistance furnace offers the precise temperature regulation and stable thermal field necessary to ensure a complete melt and a uniform chemical structure.

The Critical Role of Temperature Control

Handling High-Melting-Point Elements

The primary challenge in creating Al-5Er-Ti master alloys is the inclusion of Titanium (Ti).

Titanium is a high-melting-point element that resists liquification at standard aluminum processing temperatures. A resistance furnace is specifically chosen because it can sustain temperatures exceeding 1100°C.

Ensuring Complete Melting

Reaching the target temperature is only half the battle; sustaining it is equally important.

The resistance furnace provides a consistent thermal environment that ensures the Titanium is not just heated, but fully melted into the aluminum matrix. Without this sustained high heat, un-melted particles could remain, compromising the alloy's integrity.

Achieving Alloy Quality and Consistency

Creating a Stable Thermal Field

Beyond simple heat generation, the quality of the alloy depends on how that heat is distributed.

As seen in similar metallurgical processes, such as with aluminum-lithium alloys, a resistance furnace excels at providing a stable thermal field distribution. This prevents "hot spots" or "cold zones" within the crucible that could lead to inconsistent material properties.

Uniform Mixing and Homogeneity

The ultimate goal of the preparation process is chemical uniformity.

The controlled environment allows the Aluminum, Erbium, and Titanium to mix thoroughly. This ensures that the final master alloy has a consistent composition throughout, which is essential for its performance in subsequent casting or molding applications.

Understanding the Trade-offs

Precision vs. Speed

While the laboratory resistance furnace is superior for quality, it prioritizes stability over speed.

The process requires time to reach the high temperatures needed for Titanium and to stabilize the thermal field for uniform mixing. This is not a rapid-cycle method; it is a precision method designed to maximize smelting quality and ensure the proper integration of complex elements.

The Necessity of Controlled Cooling

The resistance furnace also allows for controlled thermal management, which can be critical for stress relief.

Just as with high-entropy alloy coatings, the ability to hold samples at constant temperatures helps release residual stresses. In the context of master alloys, this control prevents the formation of defects that might occur during rapid, uncontrolled cooling.

Making the Right Choice for Your Project

To ensure the success of your Al-5Er-Ti alloy preparation, align your equipment choice with your specific metallurgical goals.

- If your primary focus is complete melting of Titanium: Ensure your resistance furnace is calibrated to reliably sustain temperatures above 1100°C.

- If your primary focus is alloy homogeneity: Prioritize a furnace design that guarantees a stable thermal field to promote uniform mixing of the Aluminum matrix and additives.

By leveraging the precise thermal environment of a resistance furnace, you ensure a foundational casting process that yields a high-quality, uniform master alloy.

Summary Table:

| Feature | Resistance Furnace Performance | Impact on Al-5Er-Ti Master Alloy |

|---|---|---|

| Temperature Range | Sustained levels >1100°C | Ensures complete melting of high-melting-point Titanium (Ti). |

| Thermal Field | Stable and uniform distribution | Prevents hot/cold spots for consistent chemical composition. |

| Control Precision | High-precision thermal regulation | Facilitates thorough mixing of Al, Er, and Ti elements. |

| Cooling Profile | Controlled thermal management | Reduces residual stress and prevents structural defects. |

Elevate Your Material Research with KINTEK

Precision in master alloy preparation begins with superior thermal control. KINTEK provides industry-leading laboratory high-temperature furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—specifically designed to handle the rigorous demands of high-melting-point metallurgy. Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique Al-5Er-Ti or specialty alloy requirements.

Ready to ensure complete melting and chemical uniformity in your next project?

Contact KINTEK Today to Discuss Your Custom Solution

Visual Guide

References

- Al-5Er-Ti Master Alloy with Both Grain Refinement and Microalloying Effects. DOI: 10.3390/met15010043

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a blast drying oven support the preparation of rubidium-doped mesoporous bioactive glass? Optimized Synthesis

- Why is a precision temperature control system essential for wood carbonization? Achieve Perfect Shape Fidelity

- What is the use of furnace in laboratory? Unlock Precise High-Temperature Control for Material Transformations

- What role does a high-performance blast drying oven play in the hydrothermal reaction stage of CoO/CoSe nanoparticles?

- Why does vacuum quality impact carbon chain yield? Essential Standards for High-Yield Synthesis

- How does a high-temperature laboratory furnace facilitate the pressureless sintering (PLS) of silicon nitride ceramics?

- What role does a laboratory vacuum drying oven play in the post-treatment process of porous carbon derived from polyethylene terephthalate (PET)? Crucial for preserving material structure.

- Why is a vacuum storage environment necessary for solid polymer electrolyte films? Ensure Film Integrity & Data Accuracy