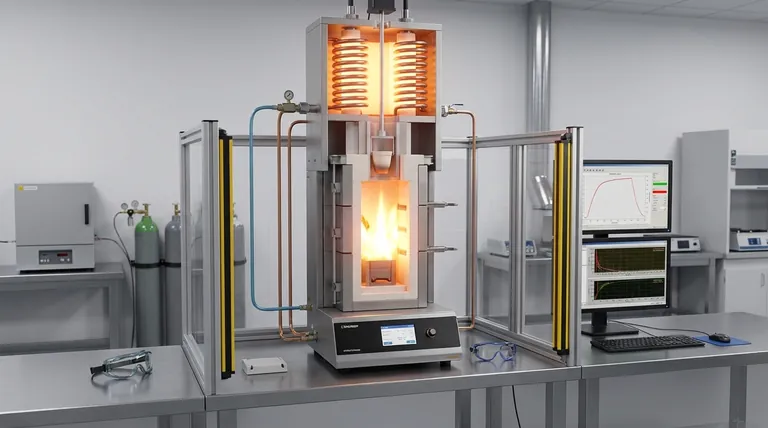

The primary function of a high-precision drop furnace is to replicate the rapid kinetic processes found in industrial concentrate nozzles within a controlled laboratory environment. By utilizing top-mounted electrical heating coils and injecting pre-heated oxygen, the apparatus precisely manages the ignition point of mineral mixtures to simulate real-world smelting conditions.

Industrial flash smelting relies on reactions that happen in the blink of an eye. This furnace isolates the critical first moments of the process, enabling the detailed study of oxidation and melting that occurs in fractions of a second.

Simulating Industrial Kinetics

Replicating the Nozzle Environment

The furnace is engineered to mimic the specific thermal and chemical conditions present at the injection point of an industrial flash smelter.

It achieves this by positioning electrical heating coils at the top of the reaction tube.

Simultaneously, pre-heated oxygen is injected to create the necessary atmosphere for immediate reaction.

Precise Ignition Control

A major challenge in smelting research is determining exactly when and where reactions begin.

This device provides the ability to precisely control the ignition starting point of the feed materials.

This control allows researchers to study specific mineral mixtures, such as chalcopyrite (CuFeS2) and silica, under consistent conditions.

Capturing Instantaneous Reactions

The 100-Millisecond Window

The chemical reactions in flash smelting are incredibly fast, often outpacing standard observation methods.

This high-precision furnace is specifically designed to capture events within a timeframe of less than 100 milliseconds.

Dynamic Observation of Melting

Beyond simple temperature readings, the furnace permits the dynamic observation of physical changes in the material.

Researchers can visually analyze exactly how particles undergo instantaneous oxidation.

It also reveals specific melting behaviors, providing insight into how the solid concentrate transforms into a molten state.

Understanding the Constraints

Focus on Initiation vs. Equilibrium

While this technology excels at analyzing the "start" of the process, it is specialized for kinetic processes, not long-term equilibrium.

It captures the rapid, transient state of ignition rather than the slow settling or phase separation that might occur later in a settling furnace.

Specificity of the Simulation

The simulation is highly specific to the nozzle region of a smelter.

Data derived from this furnace applies primarily to the flight and ignition phase of the concentrate particles.

It may not fully represent the conditions found deep within the molten bath of a full-scale industrial reactor.

Making the Right Choice for Your Research

If you are designing experiments or analyzing smelting efficiency, consider how this specific tool aligns with your objectives.

- If your primary focus is reaction kinetics: Utilize this furnace to gather data on the first 100 milliseconds of particle flight and oxidation.

- If your primary focus is burner efficiency: Use the precise ignition control to test how different oxygen temperatures affect the start of combustion.

Success in flash smelting simulations comes from understanding the micro-second behaviors that drive macro-scale efficiency.

Summary Table:

| Feature | Laboratory Drop Furnace Capability |

|---|---|

| Primary Function | Replicating industrial nozzle kinetics & flash smelting |

| Time Resolution | Captures reactions in < 100 milliseconds |

| Heating Method | Top-mounted electrical coils with pre-heated oxygen |

| Key Research Area | Ignition points, oxidation, and instantaneous melting |

| Target Materials | Mineral mixtures (e.g., Chalcopyrite and Silica) |

Elevate Your Smelting Research with KINTEK Precision

Unlock deep insights into reaction kinetics with our specialized laboratory heating solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of flash smelting simulations and material science.

Whether you need to control precise ignition points or capture sub-100ms reactions, our engineering team is ready to design a furnace tailored to your unique research goals. Contact us today to discuss your custom furnace requirements!

Visual Guide

References

- Motoo KAWASAKI, Hiromichi Takebe. Evaluation of Ignition and Combustion Reactions of CuFeS<sub>2</sub> and Silica Stone Less Than 100 ms in a Drop Furnace. DOI: 10.2473/journalofmmij.mmij-2024-010

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does programmed temperature control assist in Ti(C,N)-FeCr cermet degassing? Achieve Structural Integrity

- What technical advantages does Joule heating equipment offer? Achieving High-Efficiency Single-Atom Catalyst Synthesis

- Why is calcination essential for NaFePO4 phase formation? Engineering High-Performance Sodium Iron Phosphate

- What problem does a fluidized bed address in ceramic molds? Ensure Uniform Shells for High-Temp Casting

- What is the significance of using a high-precision gas mass flow controller for hydrogen flow? | Master Uniform Thermal Reduction

- What are the advantages of using an RTA system for CBTSe films? Precision Heating for Superior Thin Film Stoichiometry

- Why is a heating device required when evaluating HEAs? Unlocking High-Temperature Material Performance

- What is the function of a laboratory vacuum drying oven for Fe-N-C catalysts? Preserve Nanoporous Structure