At its core, a laboratory furnace uses a controlled energy source to generate high temperatures within an insulated chamber for processing materials. While the goal is always heat, the method used to create it varies significantly. The most common technologies rely on electrical resistance, electromagnetic induction, or, less frequently in modern labs, direct fuel combustion to achieve precise thermal conditions.

The critical insight is that "laboratory furnace" is not a single device but a category of instruments. The specific heating mechanism—whether it's the radiant heat from a resistor, the magnetic energy of an induction coil, or combustion—fundamentally dictates the furnace's ideal application, speed, and precision.

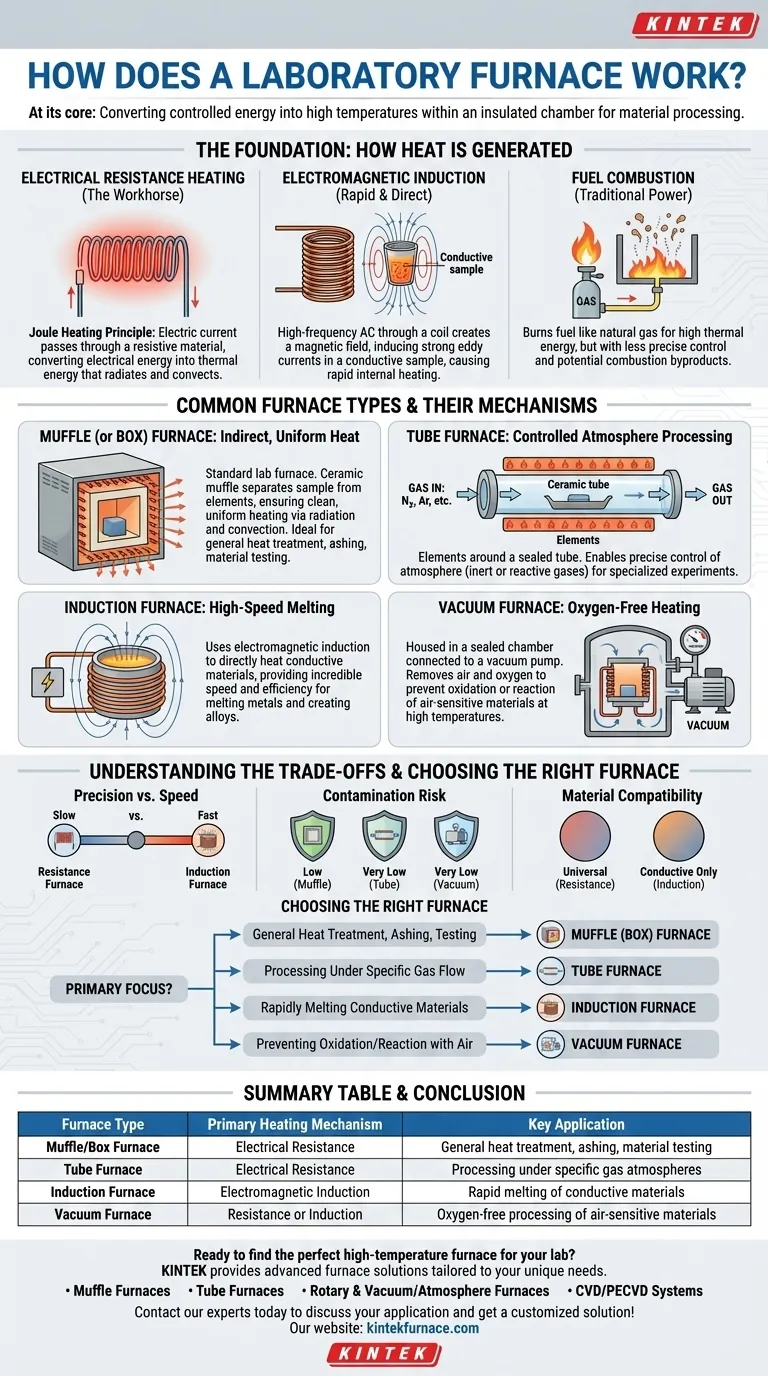

The Foundation: How Heat is Generated

Different laboratory goals require different methods of generating heat. Understanding the three primary mechanisms is the first step to mastering these essential tools.

Electrical Resistance Heating (The Workhorse)

This is the most prevalent technology in laboratory furnaces. It operates on the simple principle of Joule heating, where an electric current is passed through a material with high electrical resistance.

These heating elements, often made of alloys like Kanthal or nickel-chromium, glow red-hot as they resist the flow of electricity, converting electrical energy directly into thermal energy. This heat then radiates and convects throughout the furnace chamber to heat the sample.

Electromagnetic Induction (Rapid & Direct)

Induction heating is a fundamentally different and more direct process. It does not use a traditional heating element.

Instead, a high-frequency alternating current is passed through a copper coil. This creates a powerful, rapidly changing magnetic field around the sample. If the sample (or its crucible) is electrically conductive, this magnetic field induces strong electrical currents (eddy currents) within the material itself, causing it to heat up rapidly due to its own internal resistance.

Fuel Combustion (Traditional Power)

Though less common in precision laboratory settings today, some furnaces generate heat by burning fuel like natural gas or propane.

This method can produce a great deal of thermal energy but offers less precise temperature control and introduces combustion byproducts into the heating environment, which can contaminate a sample. It is typically reserved for applications where high power is more important than absolute purity.

Common Furnace Types and Their Mechanisms

The heating principle determines the furnace's design and its best use case.

The Muffle (or Box) Furnace: Indirect, Uniform Heat

Often called a box furnace due to its shape, a muffle furnace is the standard for many labs. It uses electrical resistance heating elements that line the walls of an insulated chamber.

The key feature is the "muffle"—an inner lining or chamber, typically made of ceramic. This muffle separates the sample from direct contact with the heating elements. This design protects the sample from contamination and promotes highly uniform heating through radiation and convection.

The Tube Furnace: Controlled Atmosphere Processing

A tube furnace is a specialized type of resistance furnace. The heating elements are arranged cylindrically around a hollow tube, which is typically made of ceramic, quartz, or metal.

Its primary advantage is atmospheric control. A sample is placed inside the tube, and the ends are sealed, allowing specific gases (like nitrogen, argon, or reactive gases) to be flowed through the tube during the heating process. This is essential for experiments that must be performed in an inert or specific chemical environment.

The Induction Furnace: High-Speed Melting

This furnace is built around the principle of electromagnetic induction. It consists of the power supply, the coil, and a crucible to hold the material.

Because it directly heats the conductive material, it is incredibly fast and efficient, making it the ideal choice for melting metals and creating alloys. The crucible can be either conductive (like graphite, which also heats up) or non-conductive, depending on the application.

The Vacuum Furnace: Oxygen-Free Heating

A vacuum furnace is not defined by its heating method but by its operating environment. It is typically a resistance or induction furnace that is housed inside a strong, sealed chamber connected to a vacuum pump.

Its purpose is to remove air and oxygen before and during the heating cycle. This is critical for processing materials that would otherwise oxidize, burn, or react with air at high temperatures.

Understanding the Trade-offs

Choosing a furnace involves balancing performance, application requirements, and cost.

Precision vs. Speed

Electric resistance furnaces offer excellent thermal stability and programmable control for slow, precise heating cycles (annealing). Induction furnaces offer unparalleled speed, capable of melting metals in minutes, but may be less stable for long soaks at a specific temperature.

Contamination Risk

Muffle furnaces provide a clean heating environment, protecting samples from the heating elements. Tube and vacuum furnaces offer the highest level of protection by completely controlling the atmosphere, eliminating contamination from air, moisture, or combustion gases.

Material Compatibility

Resistance furnaces are universal; they can heat any material placed inside them. Induction furnaces, by contrast, can only directly heat materials that are electrically conductive. Non-conductive materials can be heated in an induction furnace only if placed in a conductive (e.g., graphite) crucible.

Choosing the Right Furnace for Your Application

Your final decision should be driven entirely by your experimental or process goals.

- If your primary focus is general heat treatment, ashing, or material testing: An electric muffle (box) furnace provides the best balance of precision, cleanliness, and cost-effectiveness.

- If your primary focus is processing samples under a specific gas flow: A tube furnace is the required tool for achieving precise atmospheric control.

- If your primary focus is rapidly melting metals or other conductive materials: An induction furnace delivers unmatched speed and efficiency for metallurgical applications.

- If your primary focus is preventing any oxidation or reaction with air: A vacuum furnace is essential for processing air-sensitive materials at high temperatures.

By matching the furnace's core heating mechanism to your material and process needs, you ensure accurate, repeatable, and reliable results.

Summary Table:

| Furnace Type | Primary Heating Mechanism | Key Application |

|---|---|---|

| Muffle/Box Furnace | Electrical Resistance | General heat treatment, ashing, material testing |

| Tube Furnace | Electrical Resistance | Processing under specific gas atmospheres |

| Induction Furnace | Electromagnetic Induction | Rapid melting of conductive materials |

| Vacuum Furnace | Resistance or Induction | Oxygen-free processing of air-sensitive materials |

Ready to find the perfect high-temperature furnace for your lab?

Your experimental success depends on precise thermal processing. KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced furnace solutions tailored to your unique needs.

Our product line includes:

- Muffle Furnaces for uniform, clean heating.

- Tube Furnaces for precise atmosphere control.

- Rotary & Vacuum/Atmosphere Furnaces for specialized processes.

- CVD/PECVD Systems for advanced material synthesis.

Benefit from our strong deep customization capability to get a furnace that precisely meets your experimental requirements.

Contact our experts today to discuss your application and get a customized solution!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is a high-temperature muffle furnace used for Ni-BN powder preheating? Achieve defect-free coating density.

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?