At its core, dental porcelain offers a combination of lifelike aesthetics and excellent biocompatibility that is difficult to match with other materials. It is the leading choice for creating restorations that are virtually indistinguishable from natural teeth, but this cosmetic advantage comes with a key trade-off regarding its durability under heavy functional stress.

The central decision when considering dental porcelain is balancing its unmatched aesthetic quality against its potential for fracture. Its suitability is determined entirely by the location of the restoration and the biting forces it will need to withstand.

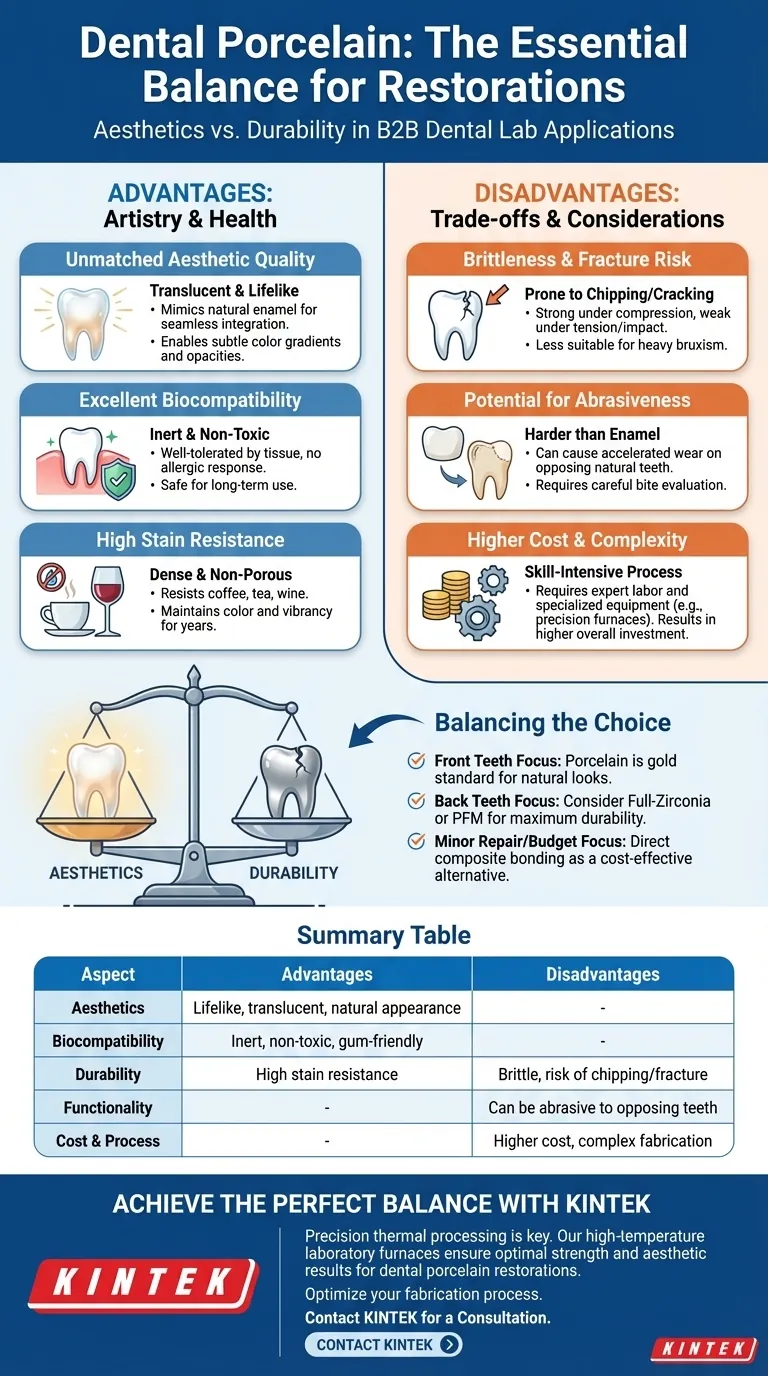

The Core Advantages of Dental Porcelain

Dental porcelain is not just a single material, but a class of highly advanced ceramics engineered specifically for use in the oral environment. Its popularity stems from several key benefits.

Unmatched Aesthetic Quality

Porcelain possesses a unique, translucent quality that mimics the light-handling properties of natural tooth enamel.

This allows dental laboratories to create crowns, veneers, and bridges that blend seamlessly with surrounding teeth. Technicians can layer different shades and opacities to replicate the subtle gradients found in a natural tooth.

Excellent Biocompatibility

Dental porcelain is an inert, non-toxic material that is exceptionally well-tolerated by the human body.

It does not provoke an allergic or inflammatory response in the surrounding gum tissue, making it a safe and reliable choice for long-term restorations.

High Stain Resistance

The surface of a finished porcelain restoration is extremely dense and non-porous, similar to glass.

This makes it highly resistant to staining from common culprits like coffee, tea, red wine, and tobacco, ensuring the restoration maintains its color and vibrancy for years.

Understanding the Trade-offs and Disadvantages

No dental material is perfect for every situation. Being objective about porcelain's limitations is crucial for ensuring a successful, long-lasting restoration.

Brittleness and Fracture Risk

The primary disadvantage of all-porcelain restorations is their relative brittleness. While very strong under compression (vertical biting), porcelain can be prone to chipping or cracking under tension or from a sharp, direct impact.

This makes it an ideal choice for front teeth, but potentially less suitable for molars in patients who clench or grind heavily, as those teeth endure immense shear forces.

Potential for Abrasiveness

Dental porcelain is harder than natural tooth enamel. Over many years, a porcelain crown can cause accelerated wear on the opposing natural tooth it bites against.

Your dentist evaluates your specific bite pattern to minimize this risk, but it remains a long-term consideration, especially in full-mouth reconstructions.

Higher Cost and Clinical Complexity

Creating a porcelain restoration is a multi-step process that requires significant skill from both the dentist and the dental laboratory technician.

The material itself, combined with the expert labor and specialized equipment (like precision furnaces) needed to craft the restoration, results in a higher cost compared to materials like composite resin or metal alloys.

How to Apply This to Your Goal

The best material is always the one that solves your specific clinical and aesthetic needs. Use these points as a guide for your discussion with your dental professional.

- If your primary focus is aesthetics for front teeth: Dental porcelain is the undisputed gold standard for achieving a natural, lifelike result.

- If your primary focus is maximum durability for a back tooth: A full-zirconia or porcelain-fused-to-metal (PFM) crown may provide better long-term resistance to fracture.

- If your primary focus is a minor repair on a budget: Direct composite bonding is a less invasive and more cost-effective, though less durable, alternative.

Understanding these fundamental properties empowers you to have a more informed discussion with your dentist about the best material for your unique situation.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Aesthetics | Lifelike, translucent, natural appearance | - |

| Biocompatibility | Inert, non-toxic, gum-friendly | - |

| Durability | High stain resistance | Brittle, risk of chipping/fracture |

| Functionality | - | Can be abrasive to opposing teeth |

| Cost & Process | - | Higher cost, complex fabrication |

Ready to Achieve the Perfect Balance for Your Dental Restorations?

At KINTEK, we understand that creating a superior dental porcelain restoration requires a perfect blend of artistry and advanced technology. Our high-temperature laboratory furnaces are engineered to provide the precise, consistent heat treatment essential for achieving the optimal strength and lifelike aesthetics that dental porcelain is known for.

Whether you are crafting crowns, veneers, or bridges, KINTEK's expertise in thermal processing supports dental laboratories in maximizing the advantages of porcelain while mitigating its limitations. Contact our experts today to discuss how our solutions can enhance your fabrication process and deliver exceptional results for your patients.

Contact KINTEK for a Consultation

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision