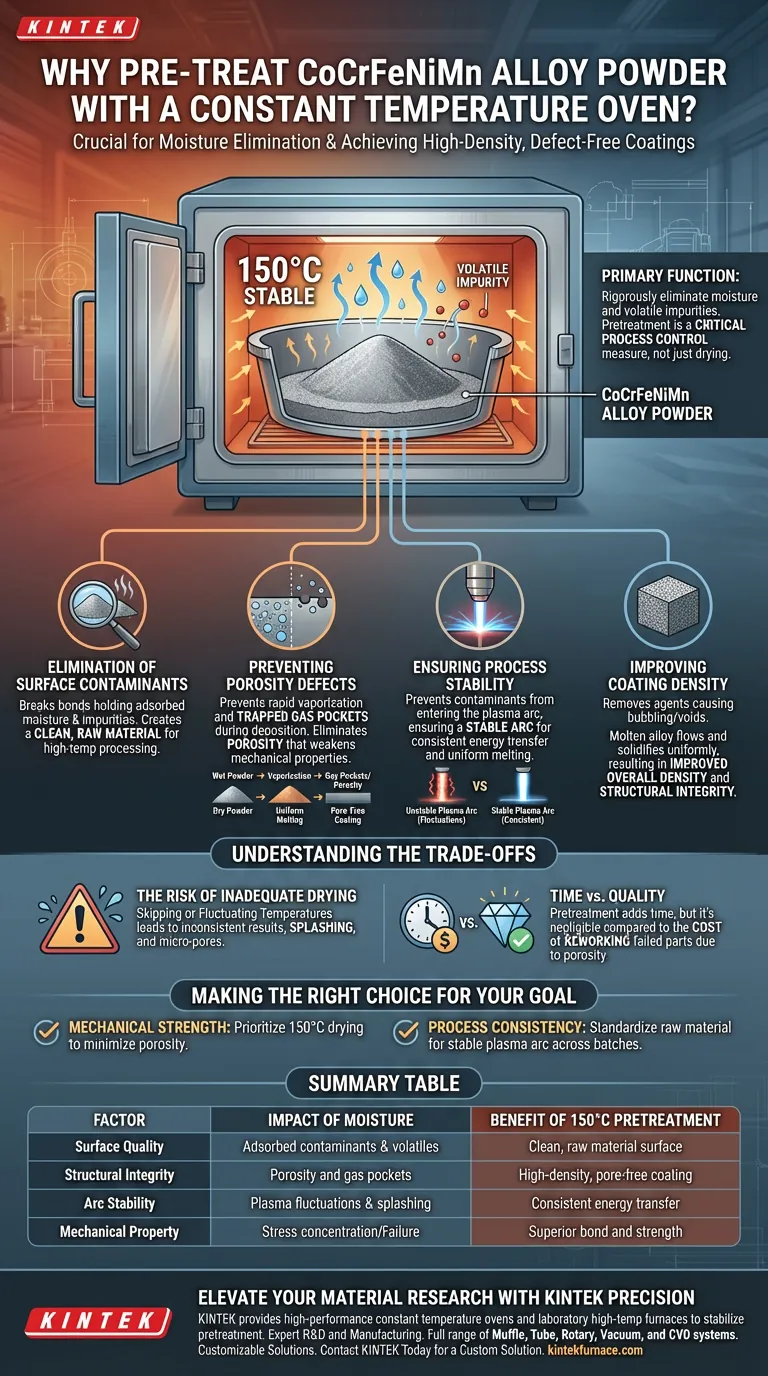

The primary function of a constant temperature oven in this context is to rigorously eliminate moisture and volatile impurities from the CoCrFeNiMn alloy powder surface. Specifically, holding the powder at 150°C ensures the material is completely dry, which is the foundational step for preventing structural failures during the subsequent deposition process.

Pretreatment is not merely about drying; it is a critical process control measure. By removing moisture and surface contaminants, you directly prevent gas formation during cladding, ensuring a stable plasma arc and a high-density, pore-free coating.

The Critical Role of Moisture Removal

Elimination of Surface Contaminants

Metal powders, including high-entropy alloys like CoCrFeNiMn, naturally adsorb moisture and volatile impurities from the surrounding environment.

Using a constant temperature oven at 150°C provides the thermal energy necessary to break the bonds holding these adsorbates to the powder surface. This creates a clean, raw material ready for high-temperature processing.

Preventing Porosity Defects

The most significant threat to coating quality is trapped gas. If moisture remains on the powder, it rapidly vaporizes when hitting the high heat of the deposition source.

This vaporization creates gas pockets that become trapped within the solidifying metal. These pockets manifest as porosity defects, which significantly weaken the mechanical properties of the final cladding layer.

Ensuring Process Stability

Moisture and volatile impurities introduce variables into the deposition environment.

When these contaminants enter the plasma arc, they can cause fluctuations and instability. By drying the powder, you ensure the plasma arc remains stable, allowing for consistent energy transfer and uniform melting of the alloy.

Improving Coating Density

The ultimate goal of cladding is a dense, solid layer of material.

By removing the agents that cause bubbling and voids (moisture and volatiles), the molten alloy can flow and solidify uniformly. This results in a cladding layer with improved overall density and superior structural integrity.

Understanding the Trade-offs

The Risk of Inadequate Drying

Skipping this step or using an oven with fluctuating temperatures can lead to inconsistent results. Even trace amounts of moisture can cause splashing or micro-pores that compromise the bond with the substrate.

Time vs. Quality

This pretreatment adds time to the production cycle. However, this time investment is negligible compared to the cost of reworking a failed part due to porosity or poor adhesion caused by "wet" powder.

Making the Right Choice for Your Goal

To ensure the success of your CoCrFeNiMn deposition, consider your specific objectives:

- If your primary focus is mechanical strength: Prioritize the 150°C drying cycle to minimize porosity, as pores act as stress concentration points that lead to failure.

- If your primary focus is process consistency: Use the oven to standardize your raw material, ensuring the plasma arc remains stable and predictable across different batches.

Treat powder dehydration not as a suggestion, but as a mandatory prerequisite for achieving high-density, defect-free alloy coatings.

Summary Table:

| Factor | Impact of Moisture | Benefit of 150°C Pretreatment |

|---|---|---|

| Surface Quality | Adsorbed contaminants & volatiles | Clean, raw material surface |

| Structural Integrity | Porosity and gas pockets | High-density, pore-free coating |

| Arc Stability | Plasma fluctuations & splashing | Consistent energy transfer |

| Mechanical Property | Stress concentration/Failure | Superior bond and strength |

Elevate Your Material Research with KINTEK Precision

Don't let moisture compromise your CoCrFeNiMn alloy performance. KINTEK provides high-performance constant temperature ovens and laboratory high-temp furnaces specifically designed to stabilize your pretreatment workflows.

Backed by expert R&D and manufacturing, we offer a full range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique thermal processing needs. Ensure process consistency and defect-free results with our industry-leading technology.

Contact KINTEK Today for a Custom Solution

Visual Guide

References

- Bo Zhang, Yu Li. The Effect of Heat Treatment on the Microstructure and Mechanical Properties of Plasma-Cladded CoCrFeNiMn Coatings on Compacted Graphite Iron. DOI: 10.3390/coatings14040374

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why is an electric blast drying oven required for CRP microstructure analysis? Ensure Data Accuracy with Proper Drying

- Why is the selection of electrode materials critical for the Plasma Flash Sintering (PFS) of titanium dioxide samples?

- Why are raw materials compacted into briquettes for vacuum carbothermal reduction? Optimize Your Magnesium Production

- What technical requirements are placed on heating equipment for fast pyrolysis? Master High-Yield Bio-Oil Production

- Why is continuous removal of carbon essential for methane pyrolysis reactors? Protect Your Reactor's Integrity

- How does a high-temperature sintering furnace influence ZnO nanotube sensors? Unlock Peak Sensitivity and Stability

- What are the benefits of thermal cycling furnaces? Boost Speed, Efficiency, and Durability

- How does a vacuum drying oven contribute to the structural stability of silicon-based composite electrode sheets?