A vacuum drying oven enhances the structural stability of silicon-based composite electrodes by facilitating tight mechanical and electrical contact between the active materials and the current collector. By operating under reduced pressure, the oven lowers the boiling point of solvents, allowing for the complete removal of moisture and residues at moderate temperatures (e.g., 80 °C) while preventing the active silicon components from reacting with residual oxygen.

Core Insight: The structural integrity of a silicon electrode relies on the purity of the interface between the coating and the foil. A vacuum drying oven achieves this by enabling deep solvent evaporation without the high thermal stress that typically causes material degradation or oxidation.

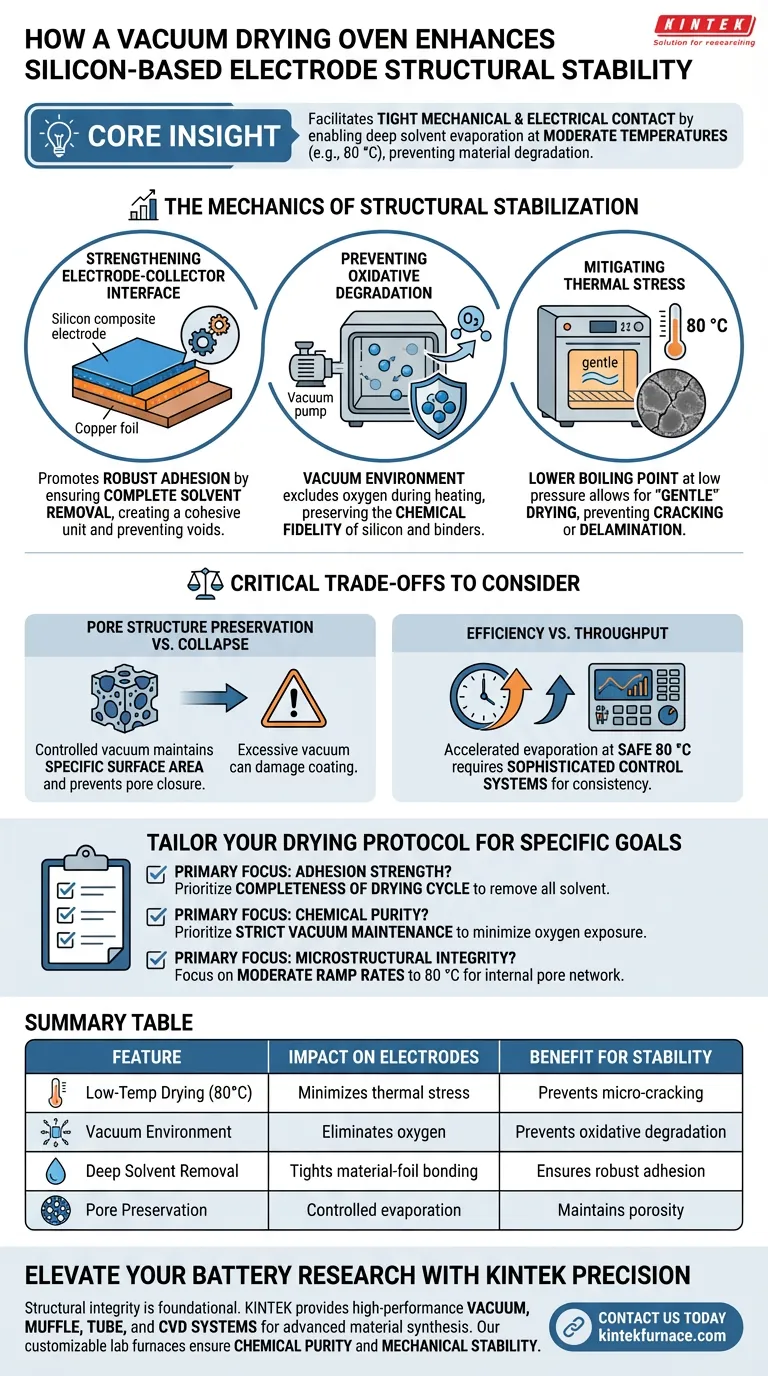

The Mechanics of Structural Stabilization

Strengthening the Electrode-Collector Interface

The primary contribution of the vacuum drying process is the promotion of robust adhesion. For composites like Si/Al2O3/RGO coated on copper foil, the presence of residual solvents can create voids or weak points in the coating.

By ensuring the complete removal of these solvents, the vacuum process allows the active material slurry to bond tightly with the copper current collector. This creates a cohesive unit that can better withstand the physical stresses of battery cycling.

Preventing Oxidative Degradation

Silicon and many composite binders are sensitive to environmental factors. Standard drying methods involving hot air can expose these materials to oxidation, altering their chemical composition before the battery is even assembled.

The vacuum environment effectively excludes oxygen during the heating phase. This preserves the chemical fidelity of the silicon and the surrounding matrix (such as RGO or alumina coatings), ensuring that the structural backbone of the electrode remains chemically inert and stable.

Mitigating Thermal Stress

High temperatures can induce thermal shock or structural collapse in delicate composite microstructures. Because the vacuum lowers the boiling point of solvents, drying can occur at a relatively low temperature, specifically around 80 °C for these silicon composites.

This "gentle" drying prevents the rapid expansion or contraction that might otherwise cause cracking or delamination of the electrode sheet.

Critical Trade-offs to Consider

While vacuum drying is superior for structural stability, it introduces specific processing considerations that must be managed.

Pore Structure Preservation vs. Collapse

A key advantage of vacuum drying is the preservation of internal porosity. As noted in broader applications, rapid evaporation at low temperatures prevents the "pore closure" often seen in high-temperature atmospheric drying.

However, if the pressure is dropped too aggressively, solvent flash-boiling can occur, potentially damaging the coating's surface. The process relies on a controlled balance between vacuum level and temperature to maintain the material's specific surface area.

Efficiency vs. Throughput

Operating at 80 °C is safer for the material but theoretically slower than high-temperature baking. The vacuum compensates for this by accelerating evaporation rates.

The trade-off is equipment complexity; maintaining a dynamic, low-oxygen vacuum requires more sophisticated control systems than standard convection ovens to ensure consistency across the entire electrode sheet.

Making the Right Choice for Your Goal

To maximize the stability of your silicon-based electrodes, tailor your drying protocol to your specific performance metrics.

- If your primary focus is Adhesion Strength: Prioritize the completeness of the drying cycle to remove every trace of solvent, ensuring no voids exist between the active material and the copper foil.

- If your primary focus is Chemical Purity: Prioritize strict vacuum maintenance to minimize partial pressure of oxygen, preventing the formation of insulative oxide layers on the silicon particles.

- If your primary focus is Microstructural Integrity: Focus on moderate ramp rates to 80 °C to allow solvent escape without disrupting the internal pore network of the composite.

Ultimately, the vacuum drying oven is not just a dehydration tool; it is a critical manufacturing step that locks in the mechanical and electrical continuity required for high-performance silicon anodes.

Summary Table:

| Feature | Impact on Silicon Electrodes | Benefit for Structural Stability |

|---|---|---|

| Low-Temp Drying (80°C) | Minimizes thermal stress and expansion | Prevents micro-cracking and coating delamination |

| Vacuum Environment | Eliminates oxygen during heating | Prevents oxidative degradation of silicon and binders |

| Deep Solvent Removal | Facilitates tight material-to-foil bonding | Ensures robust adhesion and electrical conductivity |

| Pore Preservation | Controlled solvent evaporation rates | Maintains critical internal porosity and surface area |

Elevate Your Battery Research with KINTEK Precision

Structural integrity is the foundation of high-performance silicon anodes. At KINTEK, we understand that precise thermal processing is non-negotiable for next-generation energy storage. Backed by expert R&D and world-class manufacturing, we provide high-performance Vacuum, Muffle, Tube, and CVD systems tailored specifically for advanced material synthesis.

Whether you are drying delicate composite electrodes or developing complex silicon-based architectures, our customizable lab furnaces ensure chemical purity and mechanical stability every time. Contact us today to discover how KINTEK’s specialized heating solutions can optimize your lab’s workflow and electrode performance.

Visual Guide

References

- Xiangyu Tan, Xin Cai. Reduced graphene oxide-encaged submicron-silicon anode interfacially stabilized by Al<sub>2</sub>O<sub>3</sub> nanoparticles for efficient lithium-ion batteries. DOI: 10.1039/d4ra00751d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the key differences between batch and continuous processing furnaces? Optimize Your Thermal Processing Strategy

- How do vertical reaction furnaces simulate blast furnace reduction? Recover Iron from Steel Waste Effectively

- What is the role of mortar grinding combined with heat gun processing in catalyst synthesis? Achieving PtCln Dispersion

- What is the function of controlled hot air flow treatment in ZnO drying? Master Surface Flatness and Stress Reduction

- Why is argon particularly attractive for industrial applications? Unlock Cost-Effective Purity and Stability

- What are the technical advantages of using high-purity hydrogen as a protective atmosphere? Boost Heat Treatment Speed

- How does the precise control of heating rates affect sewage sludge biochar? Master Stability & Metal Stabilization

- Why is specialized dewaxing and annealing necessary for glass-to-metal seals? Ensure Hermeticity and Clarity