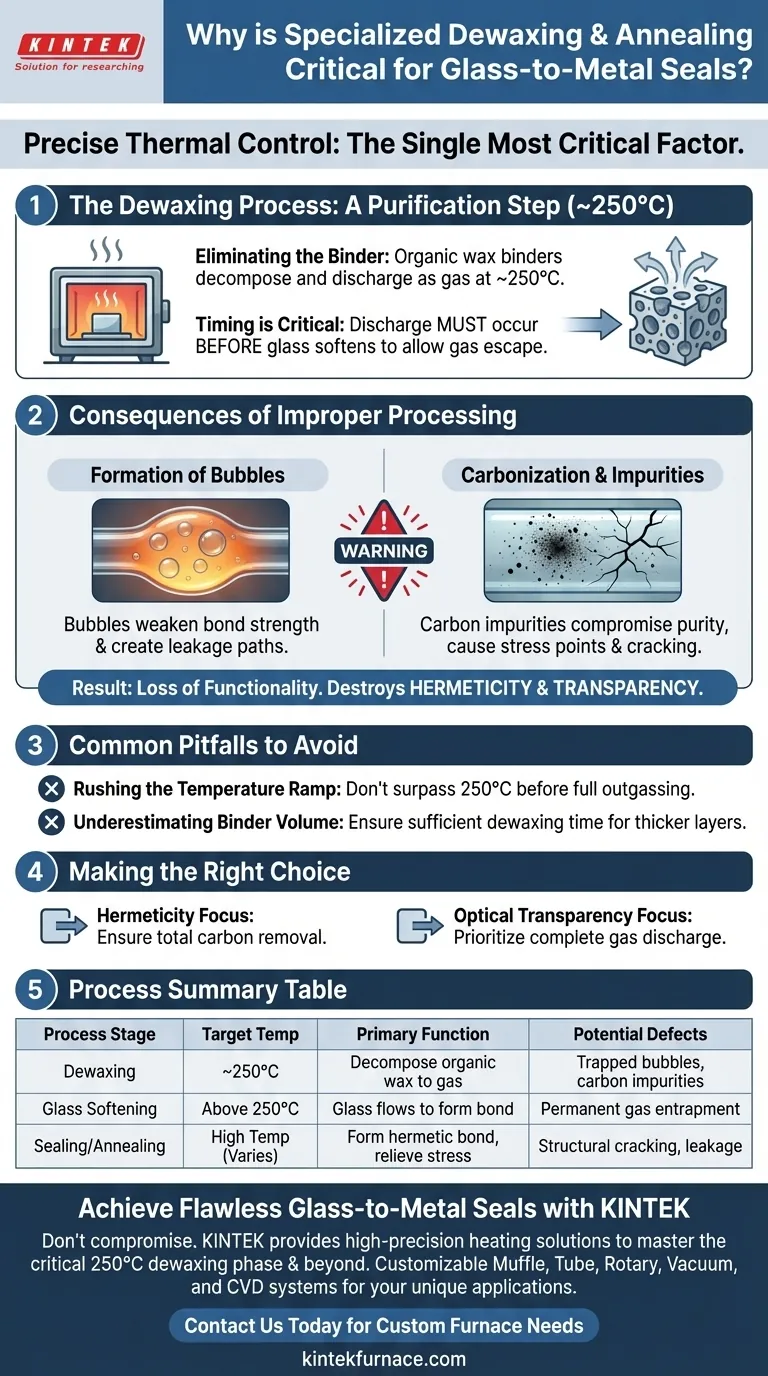

Precise thermal control is the single most critical factor in manufacturing reliable glass-to-metal seals. Specifically, a specialized dewaxing process, which involves heating the sample to approximately 250°C, is necessary to decompose organic wax binders into gas. If this step is skipped or mishandled, these binders remain trapped, leading to structural and visual defects during the subsequent high-temperature sealing stages.

Core Takeaway The dewaxing phase acts as a purification step that must occur before the glass softens. Its primary function is to fully discharge organic binders to prevent the formation of carbonized impurities and gas bubbles, which are the leading causes of seal failure.

The Mechanics of Dewaxing

Eliminating the Binder

Glass-to-metal sealing often utilizes an organic wax binder to hold materials in place prior to firing. However, this binder becomes a contaminant once the heating process begins.

You must heat the assembly to roughly 250°C to address this. At this specific temperature, the organic binder decomposes and discharges completely as a gas.

Timing is Critical

This discharge must happen before the glass reaches its softening point.

If the binder is not removed while the structure is still porous, the gas will have no escape route once the glass begins to flow and seal.

Consequences of Improper Processing

Formation of Bubbles

If the dewaxing step is insufficient, the decomposing binder releases gas inside the now-molten glass.

This results in bubbles trapped within the sealing layer. These voids weaken the mechanical strength of the bond and create leakage paths.

Carbonization and Impurities

Organic binders that are not properly discharged will eventually carbonize at higher sealing temperatures.

This leaves behind carbonized organic impurities. These inclusions compromise the purity of the glass, leading to stress points and potential cracking.

Loss of Functionality

The presence of bubbles and carbon defects directly impacts the final performance of the component.

Specifically, these defects destroy the hermeticity (airtightness) of the seal and ruin its transparency, which is critical for optical applications.

Common Pitfalls to Avoid

Rushing the Temperature Ramp

A common mistake is increasing the temperature too quickly past the 250°C mark.

If the temperature rises to the glass sealing point before the binder has fully outgassed, the impurities become permanently locked inside the seal.

Underestimating Binder Volume

The duration of the dewaxing phase must be sufficient for the volume of binder used.

Thicker layers or higher concentrations of binder require strict adherence to the dewaxing temperature to ensure the material is fully discharged.

Making the Right Choice for Your Goal

To ensure a high-yield manufacturing process, tailor your thermal profile to prioritize defect removal.

- If your primary focus is Hermeticity: Ensure the 250°C dwell time is sufficient to remove all carbon sources, as these impurities create leak paths in the final seal.

- If your primary focus is Optical Transparency: Prioritize the complete discharge of gas during the dewaxing phase to prevent bubbles from clouding the glass layer.

A clean, bubble-free pre-form is the only foundation upon which a durable glass-to-metal seal can be built.

Summary Table:

| Process Stage | Target Temperature | Primary Function | Potential Defects if Skipped |

|---|---|---|---|

| Dewaxing | ~250°C | Decompose organic wax binders into gas | Trapped bubbles, carbon impurities |

| Glass Softening | Above 250°C | Glass flows to form the physical bond | Permanent gas entrapment |

| Sealing/Annealing | High Temp (Varies) | Form hermetic bond and relieve stress | Structural cracking, leakage |

Achieve Flawless Glass-to-Metal Seals with KINTEK

Don't let improper thermal profiling compromise your product's hermeticity or optical clarity. KINTEK provides the high-precision heating solutions needed to master the critical 250°C dewaxing phase and beyond.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our lab high-temp furnaces are fully customizable to meet the unique ramp rates and dwell times required for your specialized glass-to-metal bonding applications.

Ready to elevate your manufacturing yield? Contact us today to discuss your custom furnace needs and see how our expertise can streamline your fabrication process.

Visual Guide

References

- Zhichun Fan, Kevin P. Chen. A Hermetic Package Technique for Multi-Functional Fiber Sensors through Pressure Boundary of Energy Systems Based on Glass Sealants. DOI: 10.3390/photonics11090792

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What functions does glucose perform in lithium-ion sieve synthesis? Enhance Carbothermal Reduction for LiMnO2 Purity

- Why is a vacuum drying oven required for the pretreatment of modified zeolite? Preserve Pore Integrity for CO2 Capture

- Why is high-purity argon gas used to purge the furnace? Ensure Precision in TGA Oxidation Kinetic Tests

- How does a lab furnace use eutectic points for Boron Carbide sintering? Achieve High-Density Ceramics at Lower Heat

- How does Vacuum Degassing (VD) influence spinel inclusions in heavy rail steel? Controlling Refractory Erosion

- Why is high temperature control stability required for KAS method kinetics? Ensure Accurate Activation Energy Results

- What role does physical homogenization via planetary ball milling play in LFP precursors? Maximize Your Battery Quality

- What is the use of furnace in laboratory? Unlock Precise High-Temperature Control for Material Transformations