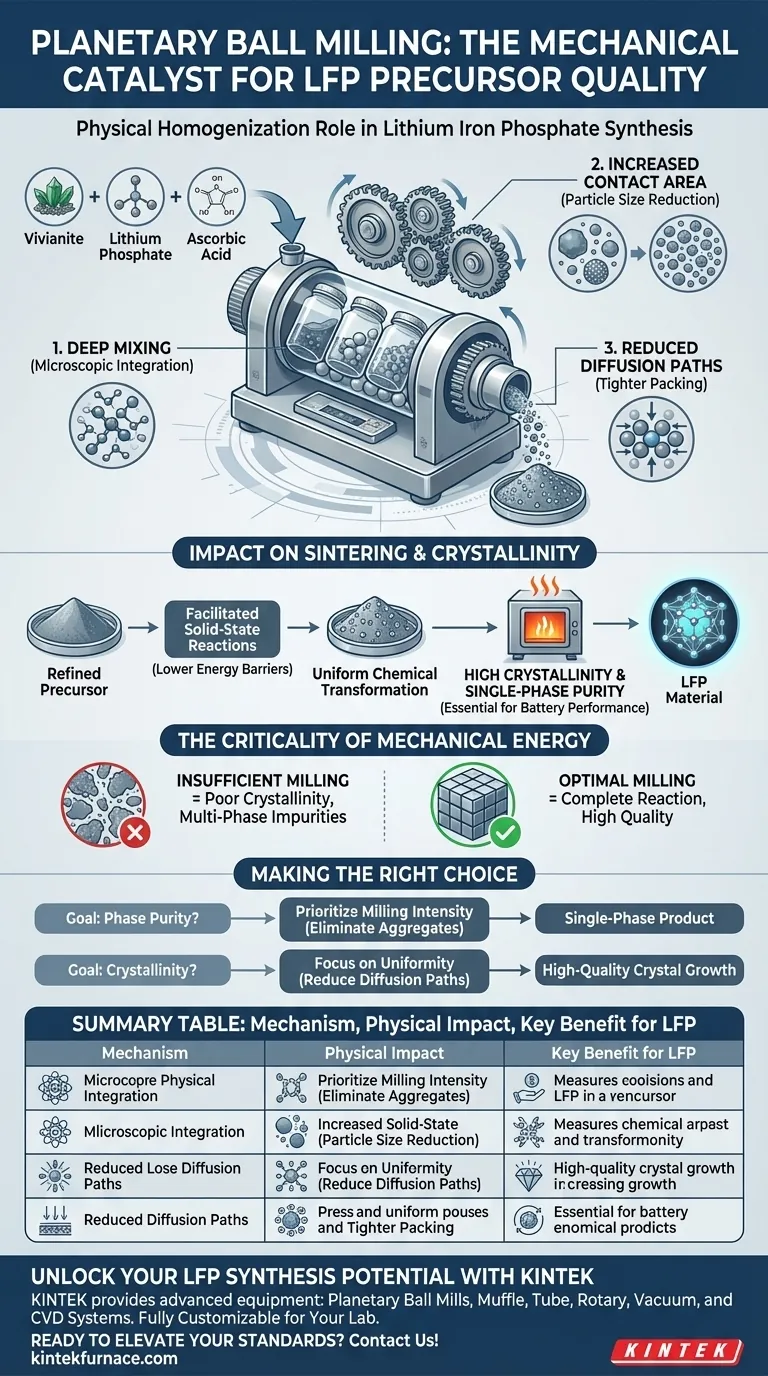

Planetary ball milling serves as the foundational mechanical catalyst for synthesizing high-quality lithium iron phosphate (LFP). It utilizes intense mechanical force to achieve deep mixing and refinement of specific raw materials, including Vivianite, lithium phosphate, and ascorbic acid.

By maximizing particle contact area and minimizing diffusion paths, planetary ball milling bridges the gap between raw ingredients and the formation of single-phase, high-crystallinity lithium iron phosphate.

The Mechanics of Precursor Refinement

Deep Mixing of Reactants

The process does more than blend ingredients; it provides the mechanical force required to intimately mix complex precursors.

Specifically, it integrates Vivianite, lithium phosphate, and ascorbic acid at a microscopic level.

This prevents the separation of ingredients that often occurs with less aggressive mixing methods.

Increasing Contact Area

The primary physical outcome of ball milling is the reduction of particle size.

By refining the raw materials, the process drastically increases the contact area between reactant particles.

This surface area maximization is the physical prerequisite for efficient chemical bonding.

Reducing Diffusion Paths

Solid-state synthesis is limited by how far atoms must travel to react with one another.

Ball milling effectively shortens these diffusion paths by pressing reactants tightly together.

This tight packing allows reactions to proceed faster and more completely during subsequent heating.

Impact on Sintering and Crystallinity

Facilitating Solid-State Reactions

The work done during milling directly impacts the efficiency of the high-temperature sintering stage.

By pre-conditioning the mixture physically, the material requires less time or lower energy barriers to react in the laboratory furnace.

This ensures the chemical transformation is uniform throughout the entire batch.

Ensuring Phase Purity

The ultimate measure of LFP quality is the formation of a single-phase structure.

Homogenization eliminates "dead zones" where unreacted materials could linger as impurities.

This uniformity leads to high crystallinity, which is essential for the electrochemical performance of the final battery material.

The Criticality of Mechanical Energy

The Cost of Insufficient Milling

It is crucial to understand that the furnace cannot correct errors made during the milling stage.

If the mechanical force is insufficient, the diffusion paths remain too long for the solid-state reaction to complete.

This results in a material with poor crystallinity or multi-phase impurities, regardless of how precise the sintering temperature is.

Making the Right Choice for Your Goal

To optimize your lithium iron phosphate synthesis, consider how milling aligns with your specific objectives:

- If your primary focus is Phase Purity: Prioritize milling intensity to eliminate all aggregates, ensuring that the Vivianite and lithium phosphate react completely to form a single-phase product.

- If your primary focus is Crystallinity: Focus on the uniformity of the mix to reduce diffusion paths, facilitating the growth of high-quality crystals during sintering.

Mastering the physical homogenization step is the only way to unlock the full chemical potential of your LFP precursors.

Summary Table:

| Mechanism | Physical Impact | Key Benefit for LFP |

|---|---|---|

| Deep Mixing | Microscopic integration of Vivianite & Li-phosphate | Prevents ingredient separation |

| Particle Refinement | Drastic increase in surface contact area | Lowers chemical bonding energy barriers |

| Diffusion Control | Reduced atomic travel distance | Enables faster, complete solid-state reactions |

| Mechanical Catalyst | Pre-conditioning of raw ingredients | Ensures high crystallinity and single-phase purity |

Unlock the Full Potential of Your LFP Synthesis

High-performance battery materials require more than just the right recipe—they demand precision at every stage. KINTEK provides the advanced equipment necessary to bridge the gap between raw ingredients and high-crystallinity lithium iron phosphate.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Planetary Ball Mills, Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique lab requirements. Whether you are optimizing phase purity or refining sintering protocols, our high-temperature furnaces and homogenization tools ensure your precursors achieve the chemical excellence they were designed for.

Ready to elevate your research and manufacturing standards? Contact us today to find your custom equipment solution!

Visual Guide

References

- Tengshu Chen, Liyao Chen. Research on the synthesis of lithium iron phosphate using vivianite prepared from municipal sludge. DOI: 10.1038/s41598-025-16378-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

People Also Ask

- What is zirconium dioxide and how is it stabilized for dental use? Discover the Science Behind Durable Dental Ceramics

- How can I improve my vacuum pump performance? Optimize Your System for Deeper Vacuum & Faster Pump-Down

- What is the role of a laboratory oven in mushroom dehydration? Master Pre-Treatment for Precise Biochemical Analysis

- How does a graphite furnace work? Achieve Ultra-Trace Element Analysis

- Why is a constant temperature drying oven required for processing lignin residue? Ensure Superior Pore Dehydration

- What are the primary purposes of using high-purity argon flow during the pyrolysis of CMS membranes? Achieve High-Purity Results

- What is the synergistic effect of industrial fly ash in beet pulp porous carbons? Enhance 3D Structural Performance

- What are the specific equipment operational requirements for the SRS process? Unlock Precise Strain Engineering