The laboratory oven acts as a critical stabilization tool in the biochemical analysis of edible mushrooms. By subjecting filtered residues to a consistent temperature of 100 degrees Celsius, the oven ensures the complete removal of moisture while simultaneously halting biological activity. This pre-treatment step is vital for converting variable biological material into a stable state ready for precise measurement.

The laboratory oven ensures analytical accuracy by completely dehydrating samples and effectively terminating enzymatic reactions. This process is essential for establishing a reliable dry mass for fiber content calculation and preventing biological changes that could skew nutrient determination results.

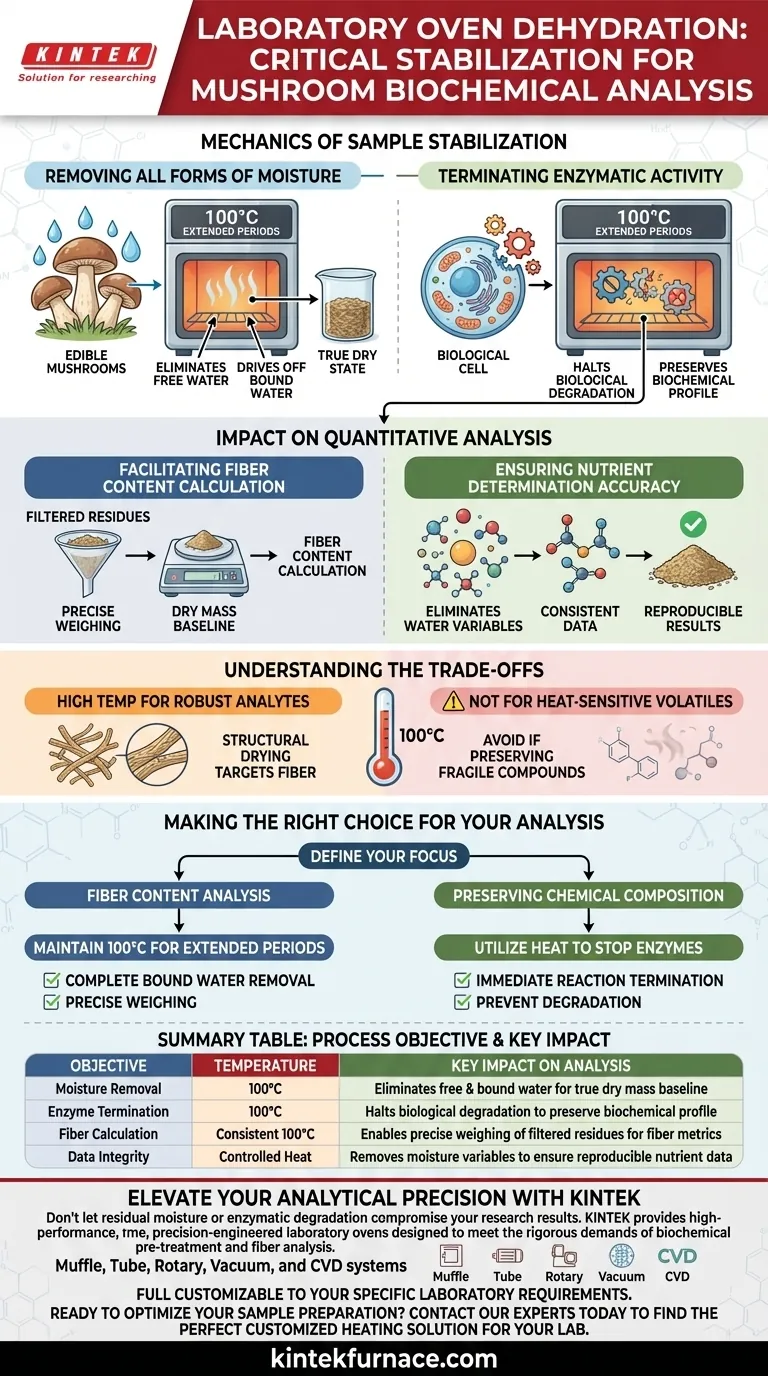

The Mechanics of Sample Stabilization

Removing All Forms of Moisture

To achieve a stable weight, it is not enough to simply air-dry samples. The laboratory oven operates at 100 degrees Celsius for extended periods to address the total water content.

This sustained heat drives off not only free water but also bound water, which is chemically locked into the cellular structure of the mushroom.

Removing both types of water is the only way to ensure the sample reaches a true "dry state."

Terminating Enzymatic Activity

Biological samples like mushrooms are dynamic systems; enzymatic reactions continue even after the mushroom is harvested or processed.

If left unchecked, these enzymes can degrade nutrients and alter the chemical composition of the sample.

The high heat of the laboratory oven effectively terminates these enzymatic reactions. This preserves the biochemical profile of the sample at the exact moment of treatment, ensuring the data reflects the true state of the mushroom.

Impact on Quantitative Analysis

Facilitating Fiber Content Calculation

The primary reference indicates that oven drying is specifically used to process filtered residues.

By reducing these residues to a completely dry state, researchers can perform precise weighing.

This dry weight serves as the fundamental baseline for calculating the percentage of fiber content accurately.

Ensuring Nutrient Determination Accuracy

Water content in biological samples fluctuates significantly, which introduces massive variables into chemical analysis.

By eliminating water as a variable, the laboratory oven allows for consistent nutrient determination.

It ensures that results are reproducible and based on the actual nutrient density of the solid matter, rather than being skewed by residual moisture.

Understanding the Trade-offs

High Temperature Considerations

While 100 degrees Celsius is standard for drying residues and fiber analysis, it is a relatively high temperature for biological samples.

The primary goal here is structural drying and enzyme termination, not necessarily the preservation of heat-sensitive volatiles.

Operators must understand that this specific pre-treatment is designed for robust analytes like fiber, where high heat helps separate the target material from water without damaging the structure being measured.

Making the Right Choice for Your Analysis

To ensure data integrity, align your oven usage with the specific metrics you need to capture.

- If your primary focus is Fiber Content Analysis: Maintain the oven at 100°C for extended periods to ensure every trace of bound water is removed from filtered residues for precise weighing.

- If your primary focus is Preserving Chemical Composition: Utilize the oven's heat to immediately stop enzymatic reactions, preventing the biological degradation of the sample's nutrient profile.

Proper oven drying transforms a biologically active mushroom sample into a stable, quantifiable substrate for rigorous scientific study.

Summary Table:

| Process Objective | Temperature | Key Impact on Analysis |

|---|---|---|

| Moisture Removal | 100°C | Eliminates free and bound water for true dry mass baseline. |

| Enzyme Termination | 100°C | Halts biological degradation to preserve the biochemical profile. |

| Fiber Calculation | Consistent 100°C | Enables precise weighing of filtered residues for fiber metrics. |

| Data Integrity | Controlled Heat | Removes moisture variables to ensure reproducible nutrient data. |

Elevate Your Analytical Precision with KINTEK

Don't let residual moisture or enzymatic degradation compromise your research results. KINTEK provides high-performance, precision-engineered laboratory ovens designed to meet the rigorous demands of biochemical pre-treatment and fiber analysis.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your specific laboratory requirements. Whether you are drying sensitive biological samples or performing high-temperature synthesis, our equipment ensures the thermal stability and uniformity your work deserves.

Ready to optimize your sample preparation? Contact our experts today to find the perfect customized heating solution for your lab.

Visual Guide

References

- Arowora Kayode Adebisi, Isaac John Umaru. Comparative Study on the Proximate and Amino Acids Levels in Selected Edible Mushroom Species. DOI: 10.58578/ajbmbr.v2i2.5892

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- What is the purpose of using high-purity nitrogen for nano-zinc oxide experiments? Ensure Data Purity & Accuracy

- How is the success of stress-relief heat treatment in AlSi10Mg verified? Ensure Part Integrity with XRD

- What role does a laboratory drying oven play in the post-treatment of Cu/ZIF-8 catalysts? Ensuring Structural Integrity

- How is mechanochemical grinding used in lithium battery recovery? Unlock Efficient Solid-State Material Repair

- How are laboratory ovens and analytical balances used for banana powder moisture content? Precision Testing Guide

- What is the necessity of an argon gas shielding system? Ensure Purity in Laser Remelting

- What are the primary technical objectives of CoCrFeMnNi alloy annealing? Master Recrystallization & Phase Control

- What is the maximum temperature capability of the furnace? Find Your Perfect High-Temp Solution