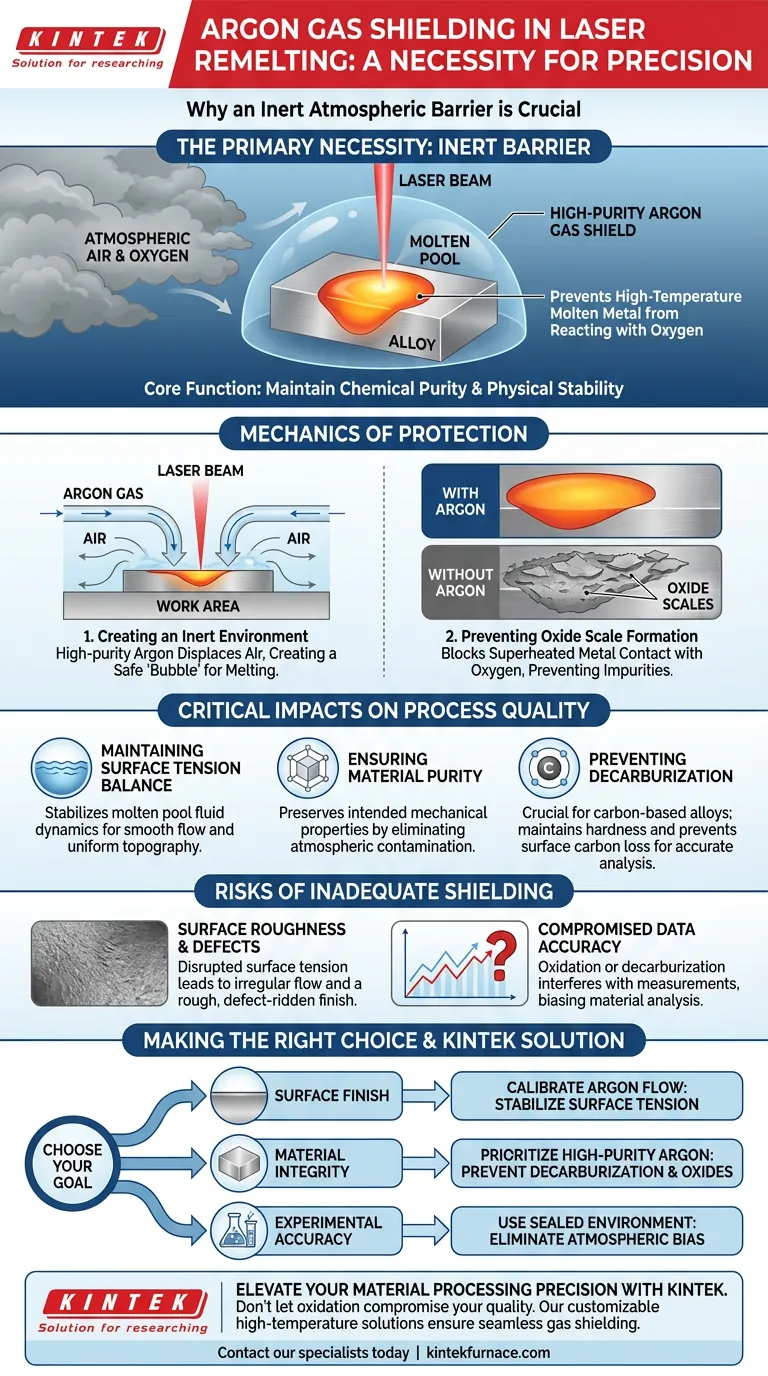

The primary necessity of an argon gas shielding system during laser remelting is to generate an inert atmospheric barrier around the process zone. This shield prevents the high-temperature molten metal from chemically reacting with oxygen in the surrounding air.

Without this protection, the molten pool would rapidly oxidize, leading to the formation of detrimental oxide scales that compromise the structural integrity and finish of the alloy.

The core function of argon shielding is to maintain the chemical purity and physical stability of the molten pool. By excluding oxygen, the system preserves the metal's natural surface tension, ensuring the final processed surface is smooth, uniform, and free of defects.

The Mechanics of Protection

Creating an Inert Environment

Laser remelting generates intense heat, rendering metallic alloys highly reactive.

The shielding system pumps high-purity argon gas over the work area to displace atmospheric air. Because argon is an inert gas, it does not react with the metal, creating a safe "bubble" for the melting process.

Preventing Oxide Scale Formation

The most immediate threat to a molten pool is oxidation.

If the superheated metal contacts oxygen, oxide scales form instantly. These scales act as impurities that weaken the material and ruin the aesthetic finish. Argon effectively blocks this reaction.

Critical Impacts on Process Quality

Maintaining Surface Tension Balance

Beyond simple chemical protection, argon plays a vital role in the physics of the fluid metal.

The primary reference notes that the shielding system helps maintain the surface tension balance of the molten pool. Stable surface tension is critical for fluid dynamics; it allows the liquid metal to flow evenly and settle into a smooth topography before solidifying.

Ensuring Material Purity

The introduction of oxygen or other atmospheric contaminants alters the alloy's composition.

By maintaining an inert atmosphere, the system ensures the purity of the remelted metal. This guarantees that the re-solidified alloy retains the specific mechanical properties intended by the engineer.

Preventing Decarburization

For carbon-based alloys, high temperatures can lead to decarburization—the loss of carbon atoms from the surface.

As highlighted in the supplementary data, an inert argon environment prevents this loss. This is crucial for maintaining the hardness of the martensitic matrix and ensures that any subsequent analysis of the material reflects its true properties, avoiding experimental bias.

Understanding the Risks of Inadequate Shielding

Surface Roughness and Defects

If the gas flow is insufficient or absent, the surface tension balance is disrupted.

This instability leads to an irregular flow of the molten metal. The result is a processed surface that is rough, uneven, and riddled with defects rather than the smooth finish required for high-performance applications.

Compromised Data Accuracy

For research or quality control, atmospheric interference is a major variable.

If oxidation or decarburization occurs, measurements of local carbon content or microstructural phases will be inaccurate. A robust shielding system eliminates this variable, providing a baseline of truth for material analysis.

Making the Right Choice for Your Goal

If your primary focus is Surface Finish: Ensure your argon flow is calibrated to stabilize surface tension, which directly results in a smoother, defect-free topography.

If your primary focus is Material Integrity: Prioritize high-purity argon to prevent decarburization and oxide inclusions, ensuring the alloy's chemical composition remains unaltered.

If your primary focus is Experimental Accuracy: Use a sealed environment to eliminate atmospheric bias, ensuring your data reflects the true properties of the alloy and not surface contamination.

Control the atmosphere, and you control the quality of the alloy.

Summary Table:

| Key Function | Primary Benefit | Impact on Quality |

|---|---|---|

| Inert Barrier | Prevents oxidation and oxide scale formation | Enhances structural integrity and aesthetic finish |

| Surface Tension Control | Stabilizes the molten pool fluid dynamics | Ensures a smooth, uniform, and defect-free topography |

| Atmospheric Displacement | Prevents decarburization in carbon-based alloys | Maintains hardness and accurate material composition |

| Purity Preservation | Eliminates atmospheric contamination | Guarantees consistent mechanical properties and data accuracy |

Elevate Your Material Processing Precision with KINTEK

Don't let oxidation compromise your research or production quality. KINTEK provides industry-leading high-temperature solutions backed by expert R&D and manufacturing. Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our equipment is fully customizable to integrate seamless gas shielding for your unique metallic alloy needs.

Ready to achieve superior surface finishes and chemical purity? Contact our specialists today to discover how KINTEK’s lab furnaces can optimize your thermal processes.

Visual Guide

References

- Microstructure and Properties of Laser-Remelted Al-Cu-Mn Alloy. DOI: 10.3390/met15070693

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

People Also Ask

- What role does a vacuum drying oven play in the post-processing of Fe3O4 magnetic nanoparticles? Ensure Phase Purity

- How does ALD of Li2CO3 contribute to NMC thin film performance? Restore Battery Capacity with Precision

- How does CFD simulation software optimize fuel combustion? Transform Furnace Efficiency with Digital Twins

- What is the purpose of coating aluminum electrodes with Au80Pd20? Enhancing Precision in Nanoparticle Characterization

- What are the material and structural requirements for heating walls? Optimize Your Externally Heated Retorting Furnace

- What is the function of PVA binder and high-pressure compression in SSBSN? Optimize Your Ceramic Green Body Preparation

- What role does an oscillating furnace play in the synthesis of quaternary Ge-Se-Tl-Sb glass alloys? Ensure Homogeneity

- What is the function of the nitrogen source in biomass pyrolysis? Optimize Bio-Oil Yield and Ensure Process Safety