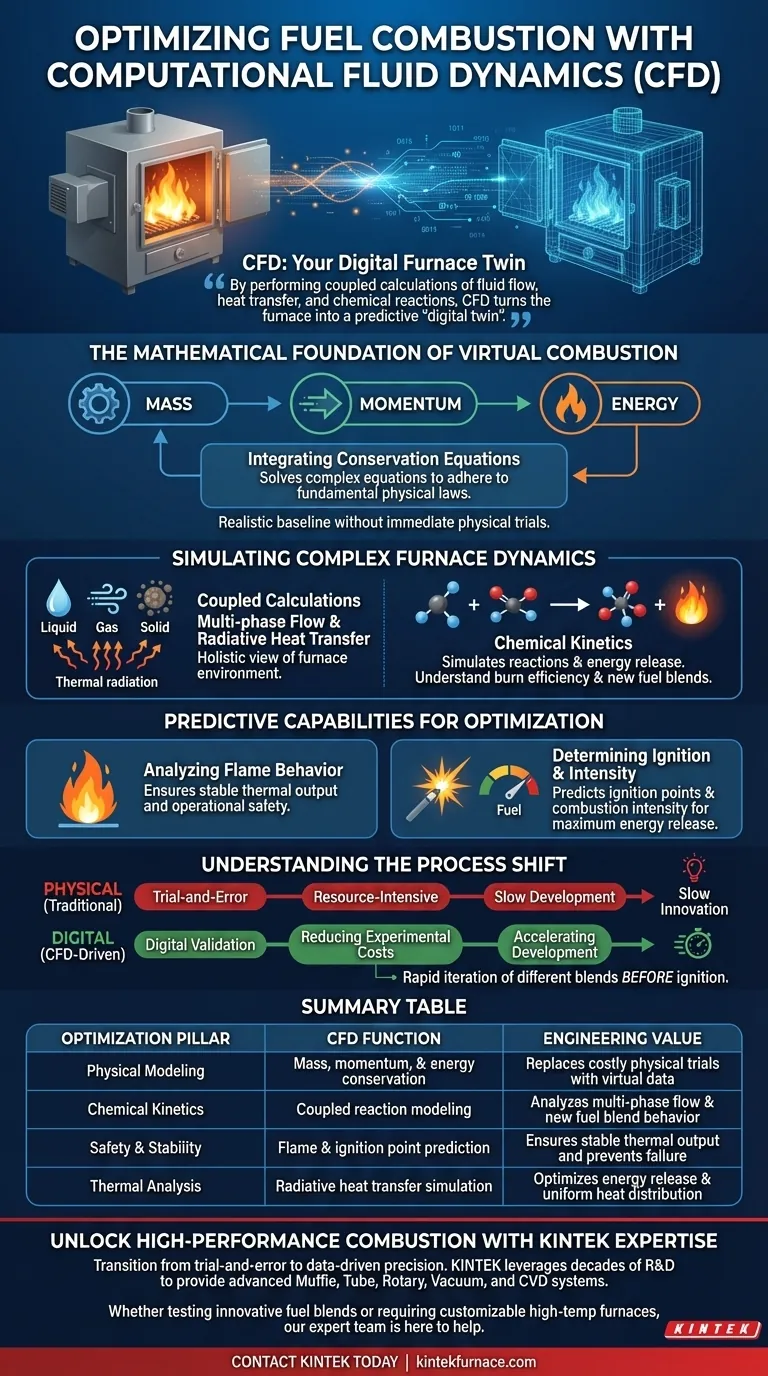

Computational Fluid Dynamics (CFD) simulation software optimizes combustion by creating a virtual environment that integrates complex physical laws to model furnace behavior. It solves conservation equations for mass, momentum, and energy to accurately simulate how fuel burns, flows, and transfers heat before any physical testing occurs.

By performing coupled calculations of fluid flow, heat transfer, and chemical reactions, CFD turns the furnace into a predictive "digital twin." This enables engineers to forecast critical behaviors like flame stability and ignition points, drastically reducing experimental costs and accelerating the deployment of new fuel blends.

The Mathematical Foundation of Virtual Combustion

Integrating Conservation Equations

At its core, CFD relies on solving complex conservation equations.

These equations account for the conservation of mass, momentum, and energy within the system.

This mathematical rigor ensures that the simulation adheres to fundamental physical laws, providing a realistic baseline for optimization without the need for immediate physical trials.

Simulating Complex Furnace Dynamics

Coupled Calculations

Combustion is not just about fire; it involves multiple interacting physics.

CFD performs coupled calculations that link different phenomena together simultaneously.

This includes modeling multi-phase flow (how solids, liquids, and gases interact) alongside radiative heat transfer to create a holistic view of the furnace environment.

Chemical Kinetics

Beyond flow and heat, CFD models the actual chemical reactions occurring in the furnace.

It simulates chemical kinetics to understand how fuel molecules break down and release energy.

This level of detail is essential for understanding the efficiency of the burn and the interactions within different fuel blends.

Predictive Capabilities for Optimization

Analyzing Flame Behavior

Engineers use these simulations to predict flame stability under various conditions.

Ensuring a stable flame is critical for consistent thermal output and operational safety.

Determining Ignition and Intensity

CFD allows for the precise prediction of ignition points.

It also forecasts combustion intensity, helping engineers tune the process for maximum energy release.

This data helps in adjusting parameters to avoid inefficiencies or dangerous unstable conditions before the fuel is ever ignited.

Understanding the Process Shift

From Physical to Digital

Traditional optimization relies heavily on trial-and-error, which is resource-intensive.

CFD shifts this paradigm by validating concepts digitally, specifically reducing experimental costs.

Accelerating Development

The software is particularly valuable when testing new fuel combinations.

It accelerates the development cycle by allowing rapid iteration of different blends, predicting their performance before actual ignition.

Making the Right Choice for Your Goal

- If your primary focus is cost reduction: Use CFD to identify the most promising fuel blends virtually, minimizing the number of expensive physical furnace tests required.

- If your primary focus is rapid innovation: Leverage the chemical kinetics modeling to quickly iterate on complex new fuel combinations that would be too slow to develop through physical experimentation alone.

CFD transforms combustion optimization from a costly experimental process into a predictive, data-driven engineering discipline.

Summary Table:

| Optimization Pillar | CFD Function | Engineering Value |

|---|---|---|

| Physical Modeling | Mass, momentum, & energy conservation | Replaces costly physical trials with virtual data |

| Chemical Kinetics | Coupled reaction modeling | Analyzes multi-phase flow & new fuel blend behavior |

| Safety & Stability | Flame & ignition point prediction | Ensures stable thermal output and prevents failure |

| Thermal Analysis | Radiative heat transfer simulation | Optimizes energy release & uniform heat distribution |

Unlock High-Performance Combustion with KINTEK Expertise

Transition from trial-and-error to data-driven precision. KINTEK leverages decades of R&D and manufacturing excellence to provide advanced Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the most demanding thermal processes.

Whether you are testing innovative fuel blends or require a customizable high-temp furnace for unique research needs, our expert team is here to help you optimize your results.

Contact KINTEK Today to discover how our high-performance lab furnaces and technical insights can accelerate your path to innovation.

Visual Guide

References

- Garikai T. Marangwanda, Daniel M. Madyira. Evaluating Combustion Ignition, Burnout, Stability, and Intensity of Coal–Biomass Blends Within a Drop Tube Furnace Through Modelling. DOI: 10.3390/en18061322

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vacuum Induction Melting Furnace

People Also Ask

- What is the role of a laboratory constant temperature drying oven? Preserving Magnetic Nanocatalyst Integrity

- Why is a laboratory vacuum oven utilized for ZnO-FL drying? Preserving Delicate Nanoparticle Morphologies

- What is the primary purpose of using nano-magnesium oxide as a template? Optimize Sulfur-Doped Porous Carbon Synthesis

- What is the significance of high-precision temperature monitoring systems in SPS? Control Ti-6Al-4V/HA Microstructure

- How are electric furnaces applied in powder metallurgy and 3D printing? Unlock Precision Sintering and Heat Treatment

- What design considerations are important for custom vacuum chambers? Optimize for Performance, Cost, and Application Needs

- Why is a specialized roasting simulation device necessary? Optimize Iron Ore Pellet Quality and Strength

- Why is precise nitrogen flow critical for AlN nanofibers? Mastering High-Performance Nitridation Results