At their core, electric furnaces are the essential final step in both powder metallurgy and many metal 3D printing workflows, responsible for transforming a fragile object made of loose metal powder into a dense, strong, and functional part. They achieve this primarily through a high-temperature process called sintering, where heat is precisely applied to fuse the metal particles together without melting them entirely.

The crucial insight is that an electric furnace in these applications is not merely an oven; it is a precision instrument for metallurgical control. The furnace's ability to manage temperature, time, and atmospheric conditions directly determines the final part's density, strength, and mechanical performance.

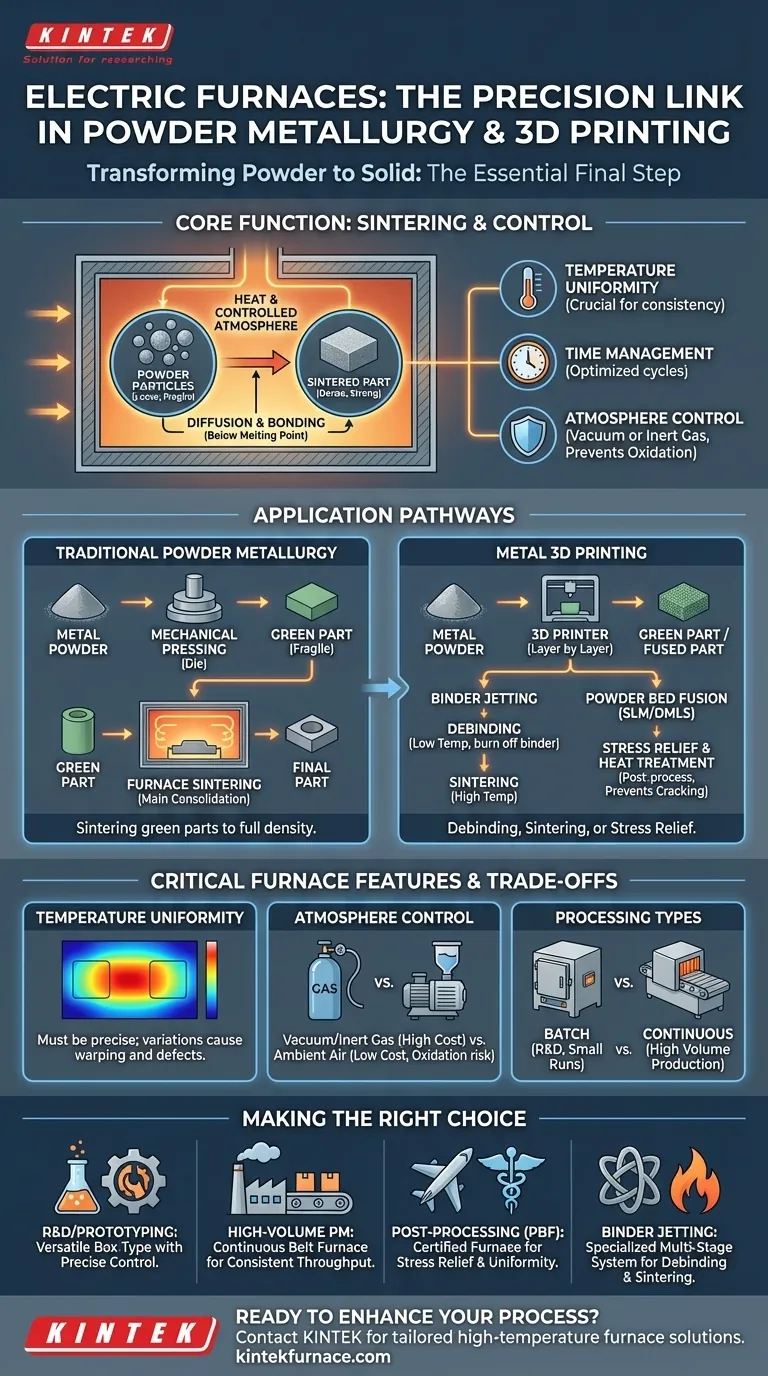

The Core Function: From Powder to Solid Part

The fundamental role of the furnace is to apply thermal energy in a highly controlled environment. This energy drives physical and chemical changes that consolidate the metal powder into a solid mass with desirable properties.

Sintering: The Foundation of the Process

Sintering is the primary function. The furnace heats the material to a temperature below its melting point, typically around 70-90% of the absolute melting temperature. At this point, atoms at the contact points of the powder particles diffuse across the particle boundaries, causing the particles to bond and the part to densify and shrink.

Heat Treatment and Stress Relief

In processes like Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM), the part is already fused in the printer. However, the rapid heating and cooling creates immense internal stress. A furnace is then used for post-process heat treatment to relieve these stresses, preventing cracking and improving the part's ductility and toughness.

Atmosphere Control: Preventing Oxidation

Heating metals to high temperatures in the presence of oxygen causes rapid oxidation (rusting), which ruins the material's properties. High-temperature electric furnaces use a vacuum or are filled with an inert gas (like Argon or Nitrogen) to create a modified atmosphere, protecting the part during the thermal cycle.

Key Differences in Application

While the underlying principles are similar, the specific role of the furnace differs significantly between traditional powder metallurgy and various 3D printing methods.

In Traditional Powder Metallurgy

In this established method, metal powder is first mechanically pressed into a desired shape using a die. This object, known as a "green part," is fragile. The furnace's role is to take this green part and sinter it into a fully dense and strong final component. This is the main consolidation step.

In Metal 3D Printing

The furnace's application depends heavily on the specific 3D printing technology used.

Binder Jetting: This process is most analogous to traditional powder metallurgy. A printer deposits a liquid binder onto a bed of metal powder, creating a green part layer by layer. This part is then placed in a furnace for a two-stage process: first, a low-temperature cycle to burn off the binder (debinding), followed by a high-temperature cycle for sintering.

Powder Bed Fusion (SLM/DMLS): Here, a laser or electron beam melts and fuses the powder within the printer itself. The furnace is not used for primary consolidation. Instead, it is a critical post-processing tool for stress relief and heat treatment (annealing) to optimize the material's microstructure and mechanical properties.

Understanding the Trade-offs and Critical Features

Choosing and operating a furnace requires understanding the balance between cost, complexity, and final part quality. These features are non-negotiable for success.

The Primacy of Temperature Uniformity

"Precise temperature control" is the most critical feature. Even minor temperature variations across the part can lead to inconsistent shrinkage, causing warping or internal defects. High-quality furnaces are designed to ensure excellent temperature uniformity throughout their heating chamber.

The Cost of Atmosphere Control

A simple furnace that operates in ambient air is the cheapest but is only suitable for materials that do not readily oxidize, such as certain ceramics. Furnaces capable of holding an inert gas atmosphere are more complex and costly. Vacuum furnaces, which provide the purest environment for highly reactive metals like titanium, represent the highest level of control and cost.

Batch vs. Continuous Processing

For research, prototyping, and small production runs, a box-type furnace is ideal. These are loaded and unloaded in individual batches. For high-volume industrial production, as seen in the automotive industry, large continuous or belt furnaces are used, where parts move through different temperature zones on a conveyor.

Making the Right Choice for Your Process

Your specific goal dictates the type of furnace and process required. The furnace is not a one-size-fits-all tool; it must be matched to the material and the manufacturing workflow.

- If your primary focus is R&D or prototyping: A versatile box-type furnace with precise temperature and atmosphere control offers the most flexibility for experimenting with different materials and cycles.

- If your primary focus is high-volume powder metallurgy: A continuous belt furnace designed for a specific sintering profile is essential for achieving consistent quality and cost-effective throughput.

- If your primary focus is post-processing for Powder Bed Fusion (SLM/DMLS): Your priority is a certified furnace for heat treatment and stress relief that guarantees exceptional temperature uniformity to meet aerospace or medical standards.

- If your primary focus is Binder Jetting: You require a system that can perform both low-temperature debinding and high-temperature sintering, often accomplished with two separate, specialized furnaces.

Ultimately, mastering the furnace is key to unlocking the full potential of any powder-based manufacturing process.

Summary Table:

| Application Area | Key Functions | Common Furnace Types |

|---|---|---|

| Powder Metallurgy | Sintering green parts to full density | Box-type, Continuous belt |

| Binder Jetting 3D Printing | Debinding and sintering | Specialized multi-stage furnaces |

| Powder Bed Fusion 3D Printing | Stress relief and heat treatment | Vacuum, Inert gas furnaces |

Ready to enhance your powder metallurgy or 3D printing process with precision electric furnaces? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored solutions can optimize your sintering, debinding, and heat treatment workflows for superior part quality and efficiency!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What core process conditions does a tube furnace provide? Mastering Catalyst Precursor Treatment

- What are the material requirements for furnace tubes? Optimize Performance and Safety in High-Temperature Labs