The synergy between a laboratory oven and a high-precision analytical balance creates a definitive method for moisture determination. This process involves weighing a precise sample of banana powder, subjecting it to constant heating at 105°C to evaporate water content, and re-weighing the dried residue. The resulting data highlights the exact mass lost, which corresponds directly to the moisture content percentages.

While the oven acts as the mechanism to drive off moisture through thermal processing, the analytical balance acts as the verifier to quantify that loss. Together, they validate whether pre-treatment processes have successfully reduced moisture to acceptable quality standards.

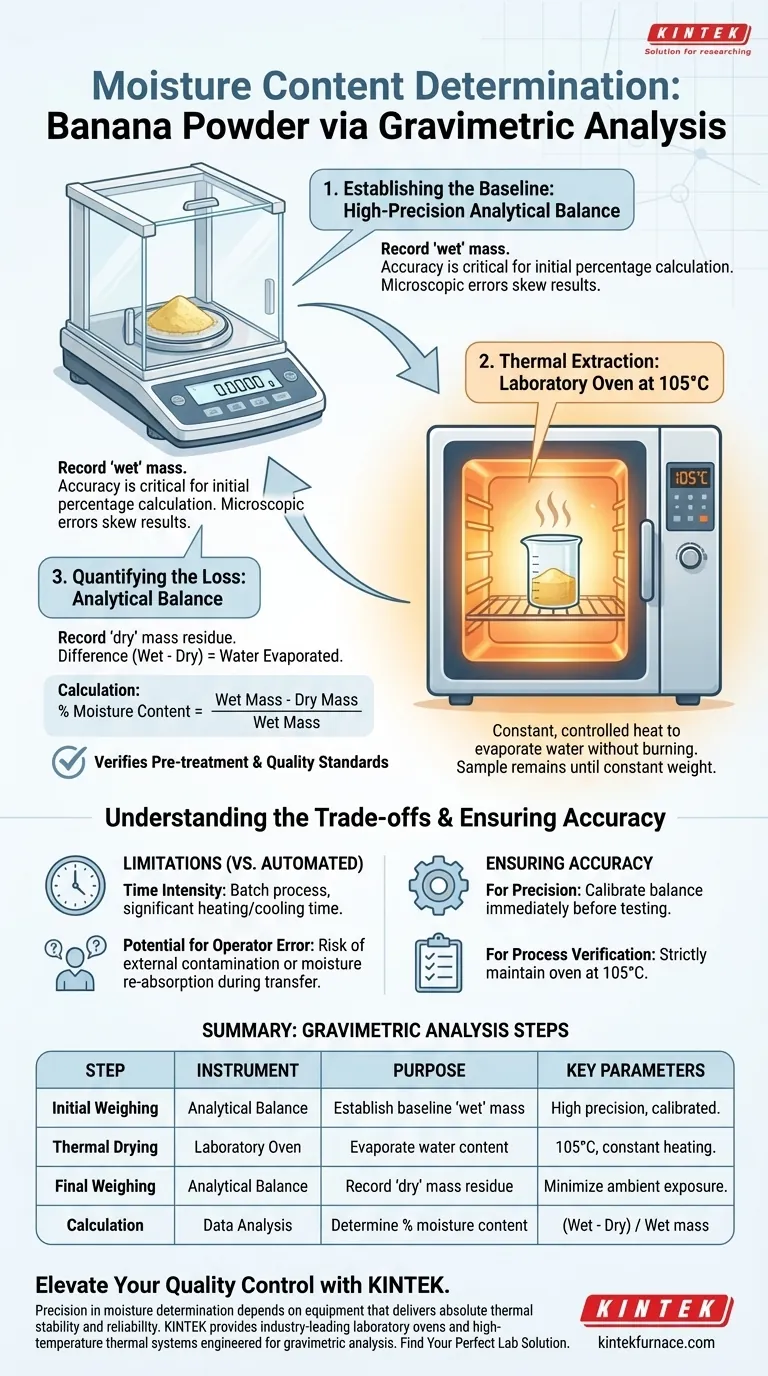

The Process of Gravimetric Analysis

To understand how these two instruments function together, one must look at the specific workflow of the oven-drying method. This method relies on the principle of differential weighing.

Establishing the Baseline

The process begins with the high-precision analytical balance. Before any heating occurs, a sample of banana powder is placed on the balance to record its initial "wet" mass.

Because moisture content is calculated as a percentage of total mass, the accuracy of this initial reading is critical. Even a microscopic error at this stage will skew the final moisture percentage calculation.

Thermal Extraction

Once the baseline is recorded, the sample is moved to the laboratory oven. The primary reference indicates that the standard operating temperature for this procedure is 105°C.

At this temperature, the oven provides constant, controlled heat sufficient to evaporate water without burning the organic solids of the banana powder. The sample remains in the oven until it reaches a constant weight, ensuring all moisture has been removed.

Quantifying the Loss

After the drying cycle, the sample is cooled and returned to the analytical balance. The instrument now records the "dry" mass.

By subtracting the final dry mass from the initial wet mass, you isolate the exact weight of the water that was evaporated. This figure confirms if the banana powder meets the necessary quality standards for shelf stability and texture.

Understanding the Trade-offs

While using an oven and balance is a standard method for verification, it is important to recognize the inherent limitations of this approach compared to automated moisture analyzers.

Time Intensity

This manual method is not instantaneous. It requires a significant amount of time to heat the sample, cool it (usually in a desiccator), and re-weigh it. It is a batch process rather than a rapid, real-time measurement.

Potential for Operator Error

Because the sample must be physically moved between the balance and the oven, there is a risk of external contamination or moisture re-absorption from the air during transfer.

Any fluctuation in the balance's calibration or the oven's temperature stability can compromise the data. This requires strict adherence to standard operating procedures (SOPs).

Ensuring Accuracy in Your Analysis

To maximize the effectiveness of combining a laboratory oven with an analytical balance, you must match your procedure to your specific quality goals.

- If your primary focus is Precision: Ensure your analytical balance is calibrated immediately prior to testing to detect minute changes in mass.

- If your primary focus is Process Verification: strictly maintain the oven temperature at 105°C to ensure the data accurately reflects the success of your pre-treatment methods.

By rigorously controlling the variables of both temperature and mass measurement, you transform raw data into a reliable certification of product quality.

Summary Table:

| Step | Instrument Used | Purpose | Key Parameters |

|---|---|---|---|

| Initial Weighing | Analytical Balance | Establish baseline "wet" mass | High precision, calibrated |

| Thermal Drying | Laboratory Oven | Evaporate water content | 105°C, constant heating |

| Final Weighing | Analytical Balance | Record "dry" mass residue | Minimize ambient exposure |

| Calculation | Data Analysis | Determine % moisture content | (Wet - Dry) / Wet mass |

Elevate Your Quality Control with KINTEK

Precision in moisture determination depends on equipment that delivers absolute thermal stability and reliability. KINTEK provides industry-leading laboratory ovens and high-temperature thermal systems engineered to meet the rigorous demands of gravimetric analysis.

Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for research labs and industrial food processing. Whether you are optimizing banana powder shelf-stability or conducting complex material characterization, our team is ready to provide the high-performance tools your project requires.

Contact KINTEK Today to Find Your Perfect Lab Solution

Visual Guide

References

- IMPACT OF DIFFERENT PRETREATMENTS ON NUTRITIONAL, FUNCTIONAL, AND COLOR PROPERTIES OF BANANA FLOUR. DOI: 10.51470/plantarchives.2025.v25.no.1.278

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the mechanism of solution treatment on Cu-Cr-Zr-La alloys? Master the Thermal Cycle for High-Strength Alloys

- What roles does a laboratory constant-temperature drying oven play in evaluating eggshell adsorbents? Key Insights

- What is the objective of coordinating mechanical stirring and heating for perovskite slurries? Achieve Homogeneity

- What is the objective of GC-MS analysis on bio-oil? Unlock Chemical Value and Industrial Utility

- How does an industrial vacuum drying oven affect electrode performance? Optimize Sodium-Ion Battery Stability

- Why are high-precision nitrogen flow meters essential during pyrolysis? Ensure Perfect Char Preparation

- What are the key requirements for steel materials in high-speed rail, nuclear power, and aerospace industries? Unlock High-Performance Steel Solutions

- What are the primary objectives of using a blast drying oven for In2O3/C nanofibers? Ensure Structural Integrity