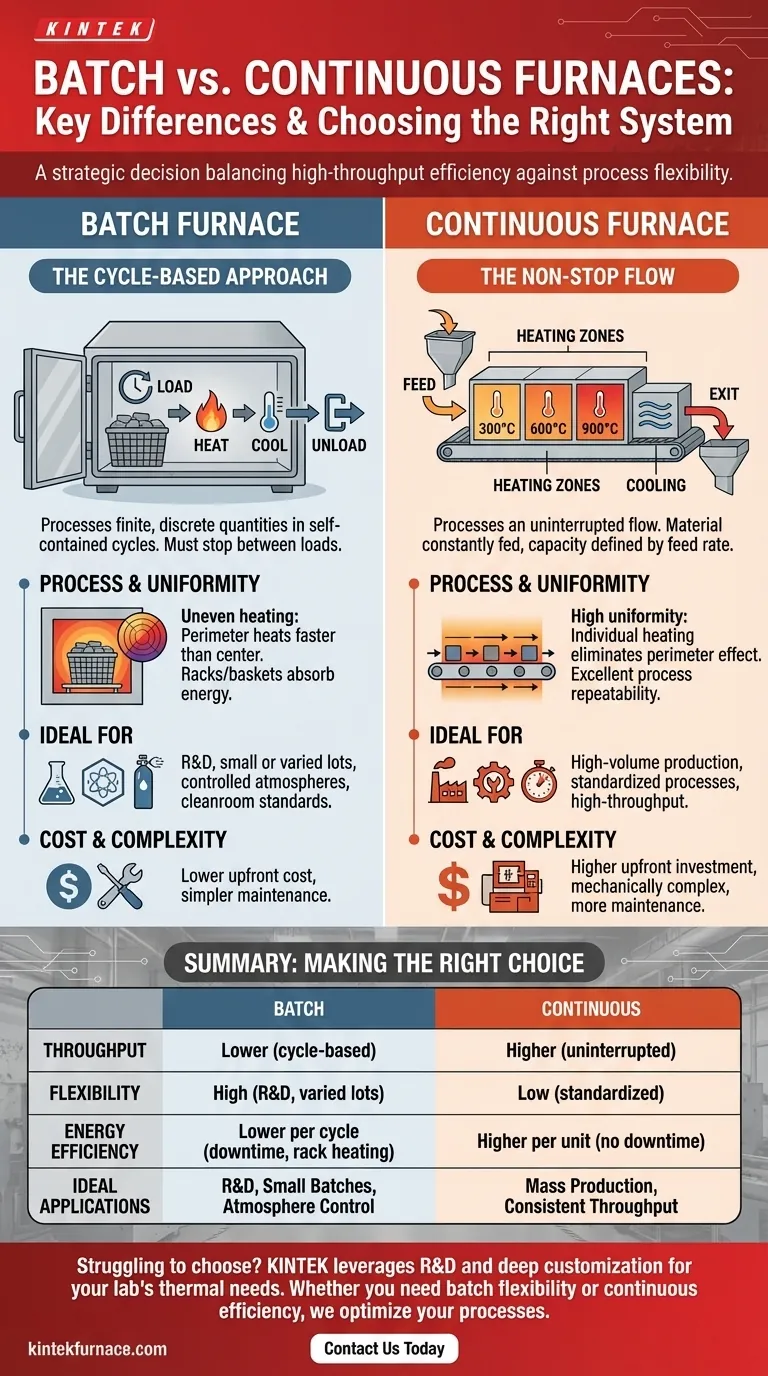

At their core, batch and continuous furnaces are distinguished by their fundamental operational model. A batch furnace processes a finite, discrete quantity of material in a self-contained cycle, while a continuous furnace processes an uninterrupted flow of material, operating without the need to stop between loads. This core difference dictates their respective strengths, weaknesses, and ideal applications.

The choice between a batch and continuous furnace is not merely about production volume. It is a strategic decision that balances the high-throughput efficiency of continuous systems against the process flexibility and control offered by batch systems.

The Fundamental Operational Difference

The primary distinction lies in how material moves through the thermal process. One operates in distinct cycles, the other in a constant flow.

How Batch Furnaces Work: The Cycle-Based Approach

A batch furnace functions as a sealed system. A specific quantity, or "batch," of material is loaded into the chamber, often using fixtures like baskets or racks.

The furnace is then sealed, heated to the target temperature for a set duration, and finally cooled down before the processed load is removed. This entire load-heat-cool-unload sequence constitutes a single cycle.

How Continuous Furnaces Work: The Non-Stop Flow

A continuous furnace is designed for uninterrupted operation. Material is constantly fed into one end of the furnace from a hopper and travels through various temperature zones before exiting the other end.

The system's capacity is not defined by the chamber size, but by the feed rate and the size of the feed and collection hoppers, which can range from a few liters to several hundred.

Process Control and Product Uniformity

How each furnace type applies heat has significant implications for the consistency and quality of the final product.

The Challenge of Uniformity in Batch Systems

In a batch furnace, the entire load must be heated simultaneously. This can lead to uneven heating, as parts on the perimeter of the load, closer to the heating elements, will heat faster than those in the center.

Furthermore, the racks or baskets used to hold the material also absorb thermal energy, increasing the overall heat load and energy consumption for each cycle.

Achieving Consistency in Continuous Systems

Continuous furnaces heat each item individually as it moves through the system at a constant, controlled speed. This eliminates the "perimeter effect" and ensures every part is exposed to the exact same temperature profile.

This method results in extremely high process repeatability and product uniformity from the first item to the last.

The Role of Heating Zones

Continuous furnaces, and some advanced batch tube furnaces, often utilize multiple heating zones. A three-zone furnace, for example, can create an exceptionally uniform temperature across its length or establish a precise temperature profile—ramping up heat, holding it, and then cooling in a controlled manner as the product moves through.

Understanding the Trade-offs

Neither system is universally superior. The optimal choice depends on balancing efficiency, cost, and process requirements.

Throughput and Energy Efficiency

For high-volume production, continuous furnaces are significantly more efficient. They eliminate the downtime required for cooling and reloading, and by not heating heavy racks or baskets, their per-unit energy consumption is much lower.

Operational Flexibility

Batch furnaces offer superior flexibility. They are ideal for research and development, processing small or varied lots, or when product recipes change frequently. Because they are sealed systems, they are also better suited for processes requiring a controlled inert atmosphere or cleanroom standards.

Cost and Complexity

Continuous furnaces represent a larger upfront investment. They are mechanically more complex, require more sophisticated control systems to manage feed rates and temperature zones, and typically demand more frequent maintenance.

Batch systems are generally simpler, less expensive to acquire, and easier to maintain.

Making the Right Choice for Your Goal

Selecting the correct furnace requires aligning the equipment's core strengths with your primary operational objective.

- If your primary focus is high-volume, standardized production: A continuous furnace offers unmatched throughput, per-unit energy efficiency, and process consistency.

- If your primary focus is process flexibility for R&D or varied lots: A batch furnace provides the adaptability needed for frequent changeovers and smaller, distinct production runs.

- If your primary focus is absolute atmospheric control or purity: The sealed-system design of a batch furnace makes it the superior choice for processes in cleanrooms or requiring inert gas.

Ultimately, understanding the distinction between cycle-based and flow-based processing empowers you to select the right tool for your specific thermal objective.

Summary Table:

| Aspect | Batch Furnace | Continuous Furnace |

|---|---|---|

| Operational Model | Processes discrete loads in cycles | Processes material in uninterrupted flow |

| Throughput | Lower, suitable for small or varied lots | Higher, ideal for high-volume production |

| Process Uniformity | Can have uneven heating; lower consistency | High uniformity with consistent temperature exposure |

| Flexibility | High; adaptable for R&D and frequent changes | Low; best for standardized processes |

| Energy Efficiency | Lower per cycle due to heating racks and downtime | Higher per unit; no downtime and minimal extra heating |

| Cost and Complexity | Lower upfront cost, simpler maintenance | Higher upfront investment, more complex systems |

| Ideal Applications | R&D, small batches, controlled atmospheres | Mass production, consistent high-throughput needs |

Struggling to choose the right furnace for your lab's needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—offers strong deep customization to precisely meet your unique experimental requirements. Whether you need the flexibility of batch processing or the efficiency of continuous systems, we can help optimize your thermal processes. Contact us today to discuss how our furnaces can enhance your productivity and results!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How should a quartz tube furnace be cleaned? Essential Steps for Safe, Contamination-Free Maintenance

- What technical requirements affect the external thermal strength of furnace tubes? Optimize for High-Temp Performance

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing

- What is the difference between an alumina tube furnace and a quartz tube furnace? Choose the Right Tube Furnace for Your Lab

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab