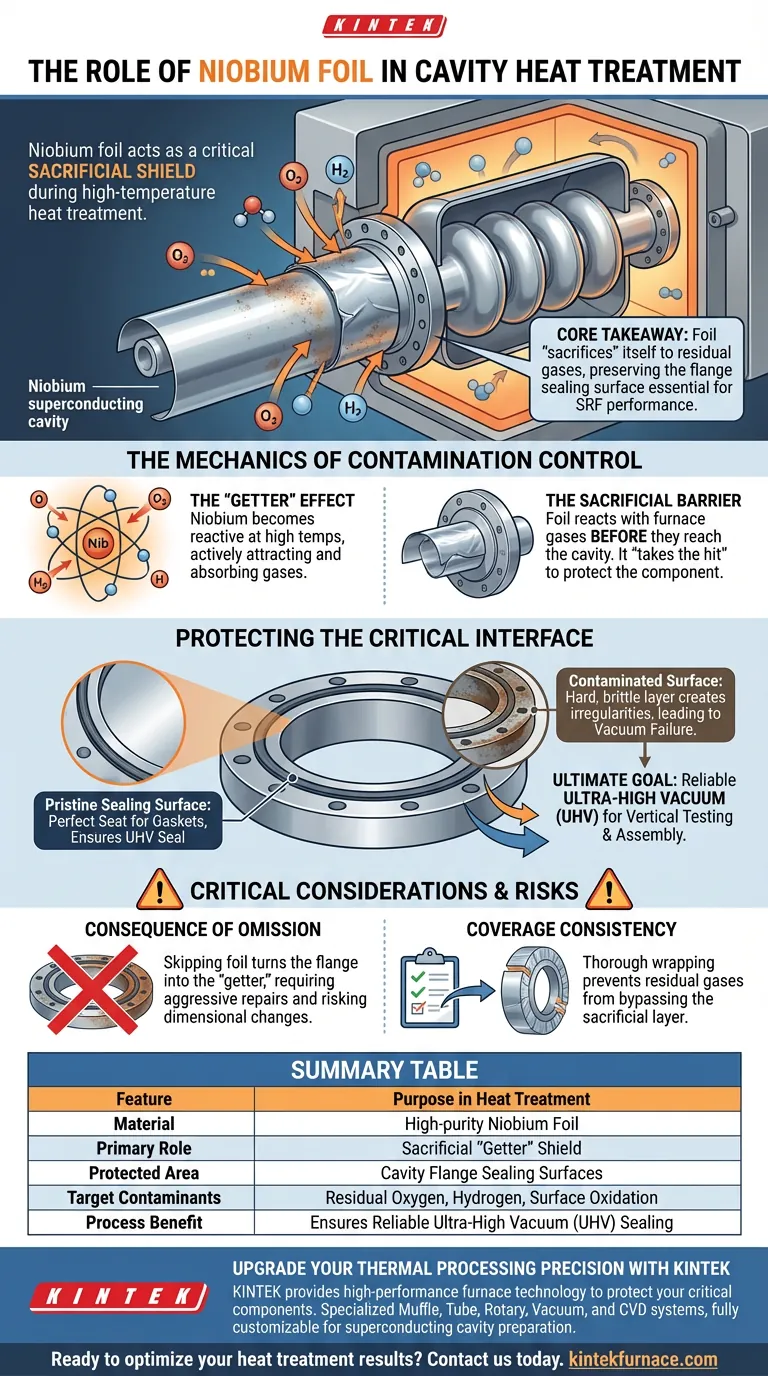

Niobium foil acts as a critical sacrificial shield wrapped around cavity flanges during high-temperature heat treatment. Its primary function is to intercept residual gases present in the furnace, preventing them from reacting with the flange's sealing surface. By absorbing these contaminants, the foil ensures the flange remains clean and capable of forming a reliable ultra-high vacuum (UHV) seal.

Core Takeaway: Even in high-quality vacuum furnaces, residual gases can oxidize niobium at high temperatures. Wrapping flanges in niobium foil effectively "sacrifices" the foil to these impurities, preserving the integrity of the sealing surface essential for superconducting radio frequency (SRF) performance.

The Mechanics of Contamination Control

The "Getter" Effect

At the high temperatures required for heat treatment, niobium becomes highly reactive. It acts as a "getter," meaning it actively attracts and absorbs gases like oxygen and hydrogen from its environment.

The Sacrificial Barrier

Because the foil is made of the same material as the cavity, it exhibits the same reactivity. By wrapping it around the flange, the foil reacts with the residual furnace gases before they can reach the cavity component.

The foil essentially "takes the hit," absorbing oxidation and contamination so the underlying flange does not.

Protecting the Critical Interface

Preserving the Sealing Surface

The specific area being protected—the flange—is the most mechanically critical part of the cavity's exterior. This surface must act as a perfect seat for gaskets to maintain a vacuum.

If this surface becomes contaminated or oxidized, it creates a hard, brittle layer. This layer creates irregularities that prevent a proper seal during assembly.

Ensuring Vacuum Integrity

The ultimate goal of this protection is reliability during the vertical testing and final assembly phases.

Superconducting radio frequency components require an Ultra-High Vacuum (UHV) to function. If the flange surface is compromised during heat treatment, the UHV seal will likely fail, rendering the component unusable until expensive repairs are performed.

Critical Considerations and Risks

The Consequence of Omission

Skipping the foil wrap is a fundamental process error. Without this barrier, the heavy, structural flange becomes the "getter" for impurities.

This results in a surface that is chemically altered, often requiring aggressive machining or polishing to restore, which risks altering the precise dimensions of the component.

Coverage Consistency

For the protection to be effective, the wrapping must be thorough. Gaps in the foil allow residual gases to bypass the sacrificial layer and attack the sealing surface directly.

Ensuring Process Reliability

To ensure the success of your niobium cavity preparation, apply the following principles:

- If your primary focus is Assembly: Inspect the sealing surfaces immediately after heat treatment; a clean surface indicates successful sacrificial protection.

- If your primary focus is Process Control: Ensure standard operating procedures mandate thorough foil coverage on all flange surfaces prior to furnace loading.

Reliable performance begins with a pristine vacuum seal, protected by the simple application of a sacrificial layer.

Summary Table:

| Feature | Purpose in Heat Treatment |

|---|---|

| Material | High-purity Niobium Foil |

| Primary Role | Sacrificial "Getter" shield |

| Protected Area | Cavity Flange Sealing Surfaces |

| Target Contaminants | Residual Oxygen, Hydrogen, and Surface Oxidation |

| Process Benefit | Ensures Reliable Ultra-High Vacuum (UHV) Sealing |

Upgrade Your Thermal Processing Precision with KINTEK

Don't let residual gas contamination compromise your SRF performance. KINTEK provides the high-performance furnace technology and expertise needed to protect your most critical components.

Backed by expert R&D and manufacturing, we offer specialized Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of superconducting cavity preparation. Whether you need precise temperature uniformity or advanced vacuum control, our lab high-temp furnaces ensure your components remain pristine.

Ready to optimize your heat treatment results? Contact us today to discuss your custom furnace needs.

Visual Guide

References

- Christopher Bate, Jacob Wolff. Correlation of srf performance to oxygen diffusion length of medium temperature heat treated cavities<sup>*</sup>. DOI: 10.1088/1361-6668/ad9fe8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the purpose of heating the nickel nitrate and biomass mixture to 150°C? Achieve Superior Catalyst Dispersion

- How does a constant temperature heating device influence rare earth leaching? Boost Extraction Efficiency to 95.72%

- What are the process advantages of using a microwave hydrothermal high-pressure reactor? Master V-NbOPO4@rGO Synthesis

- What roles does a laboratory constant-temperature drying oven play in evaluating eggshell adsorbents? Key Insights

- Why is a jaw crusher used for initial magnesite ore crushing? Maximize Efficiency & Protect Your Mill

- How does a hybrid microwave sintering furnace compare to traditional furnaces? Optimize BZT Ceramic Production

- How do h-BN targets improve memristor switching ratios? Maximize Logic Windows with High-Purity Precursors

- Why is it necessary to grind iron concentrate to 5-10 microns? Optimize Your Iron Ore Reduction Kinetics