The primary function of a vacuum oven in the heat treatment of molybdenum-based catalyst precursors is the thorough removal of moisture and volatile solvents while preventing premature oxidation. By operating at lower temperatures under reduced pressure, the oven ensures the chemical stability of the precursor pores before the material undergoes high-temperature sintering or calcination.

A vacuum oven provides a controlled, low-oxygen environment that enables deep dehydration at reduced temperatures. This step is critical to preserving the structural integrity and chemical purity of the catalyst precursor, preventing unwanted oxidative degradation and structural collapse.

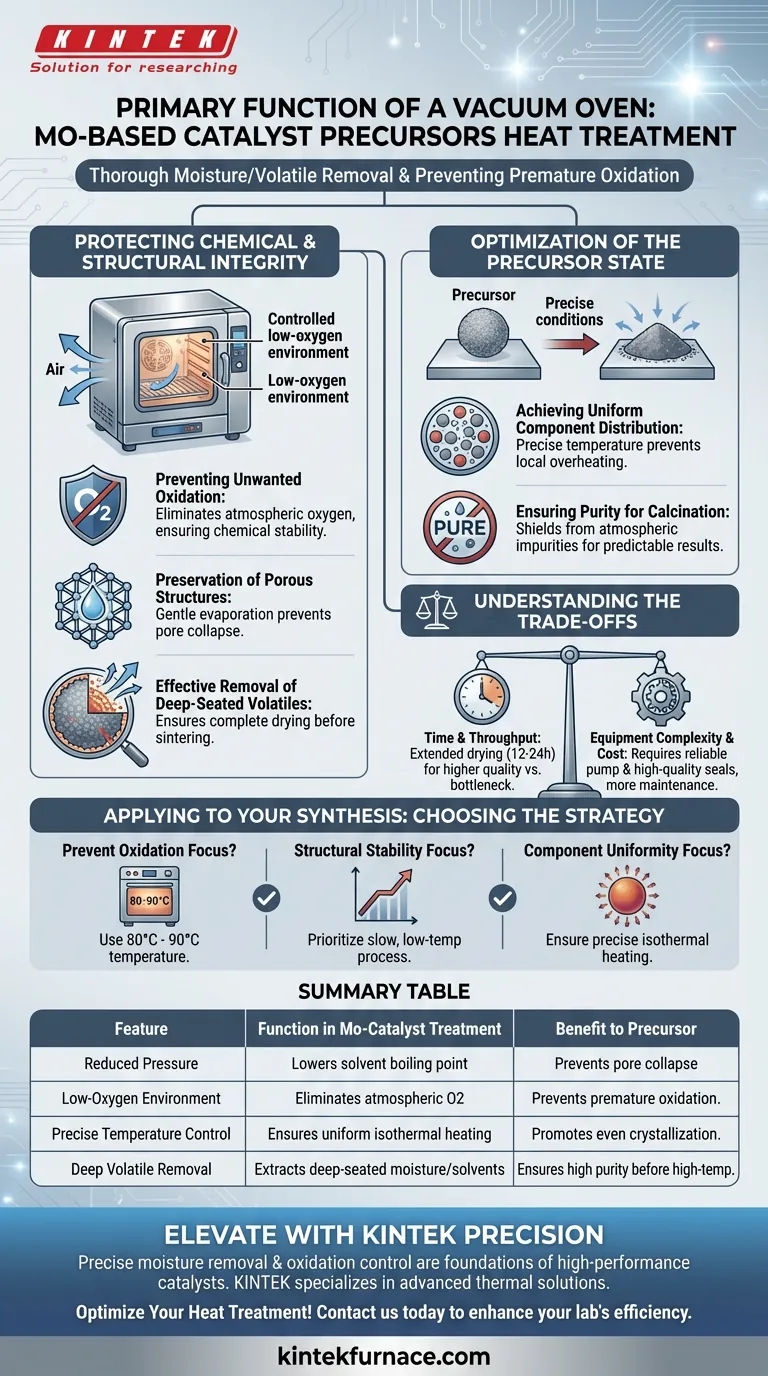

Protecting Chemical and Structural Integrity

Preventing Unwanted Oxidation

Mo-based precursors are often sensitive to atmospheric oxygen at elevated temperatures. The vacuum environment eliminates oxygen from the drying chamber, ensuring the chemical stability of the samples is maintained throughout the process.

Preservation of Porous Structures

Removing moisture within a vacuum lowers the boiling point of liquids, allowing for gentle evaporation. This prevents the "sudden evaporation" effect that can occur at atmospheric pressure, which often leads to the collapse of delicate porous structures during subsequent high-temperature stages.

Effective Removal of Deep-Seated Volatiles

Standard drying may leave residual solvents trapped deep within the precursor pores. The low-pressure environment of a vacuum oven effectively pulls these volatiles out, ensuring the precursor is completely dry before it reaches the sintering stage.

Optimization of the Precursor State

Achieving Uniform Component Distribution

Precise temperature control in the oven prevents local overheating. This ensures that nitrates and other components concentrate and crystallize gradually and uniformly throughout the solid sample.

Ensuring Purity for Calcination

By drying in a vacuum, the material is shielded from reacting with atmospheric impurities. This results in a "pure" precursor, which is essential for achieving predictable results during the final high-temperature calcination or sintering phases.

Understanding the Trade-offs

Time and Throughput Considerations

Vacuum drying often requires extended periods, such as 12-24 hours, to ensure complete dehydration. While this produces a higher quality catalyst, it can create a bottleneck in high-volume laboratory or industrial workflows.

Equipment Complexity and Cost

Operating a vacuum oven requires a reliable vacuum pump and high-quality seals that can withstand heat. Compared to standard convection ovens, these systems require more frequent maintenance to prevent oil backstreaming or vacuum leaks.

Applying This to Your Catalyst Synthesis

Choosing the Right Drying Strategy

- If your primary focus is preventing oxidation: Use a vacuum oven at temperatures between 80°C and 90°C to ensure the precursor does not react with residual oxygen.

- If your primary focus is structural stability: Prioritize a slow, low-temperature vacuum drying process to prevent pore collapse caused by rapid moisture expansion.

- If your primary focus is component uniformity: Ensure the oven provides precise isothermal heating to avoid localized hot spots that lead to non-uniform crystallization.

By meticulously controlling the vacuum drying phase, you provide a stable, pure foundation for the successful high-temperature transformation of your catalyst precursors.

Summary Table:

| Feature | Function in Mo-Catalyst Treatment | Benefit to Precursor |

|---|---|---|

| Reduced Pressure | Lowers boiling point of solvents | Prevents pore collapse from rapid evaporation |

| Low-Oxygen Environment | Eliminates atmospheric oxygen | Prevents premature oxidation of sensitive Mo-species |

| Precise Temperature Control | Ensures uniform isothermal heating | Promotes even crystallization of components |

| Deep Volatile Removal | Extracts deep-seated moisture/solvents | Ensures high purity before high-temp calcination |

Elevate Your Catalyst Synthesis with KINTEK Precision

Precise moisture removal and oxidation control are the foundations of high-performance molybdenum catalysts. At KINTEK, we specialize in providing the advanced thermal solutions required to protect your material’s structural integrity.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need a specialized laboratory vacuum oven for delicate precursor drying or a customizable high-temperature furnace for industrial calcination, our systems are engineered to meet your unique research needs.

Ready to optimize your heat treatment process? Contact us today to discover how KINTEK’s customizable laboratory furnaces can enhance your lab's efficiency and ensure the purity of your results.

Visual Guide

References

- Mengyun Hou, Chen Chen. Microenvironment reconstitution of highly active Ni single atoms on oxygen-incorporated Mo2C for water splitting. DOI: 10.1038/s41467-024-45533-3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How does a gas evolution analysis system monitor gas release? Optimize Your Casting Integrity

- Why is a high-precision substrate heating system required for BST thin films? Achieve Crystal Growth Success

- What role does a nitrogen protection device play in copper-based halide thin films? Optimize Your Lab Annealing Process

- What is the primary function of compacting PVC and metal oxide mixtures? Enhancing Dechlorination Efficiency

- What is the significance of FE-SEM for SSBSN ceramics? Master Morphological Analysis for Superior Electrical Performance

- What are the requirements for ovens in MOF synthesis? Achieve Precision Thermal Stability for High-Crystallinity

- Why is the base vacuum level of a magnetron co-sputtering system critical for Ru50Mo50(0001) alloy thin films?

- What is the temperature range of a lab furnace? Find Your Perfect Match