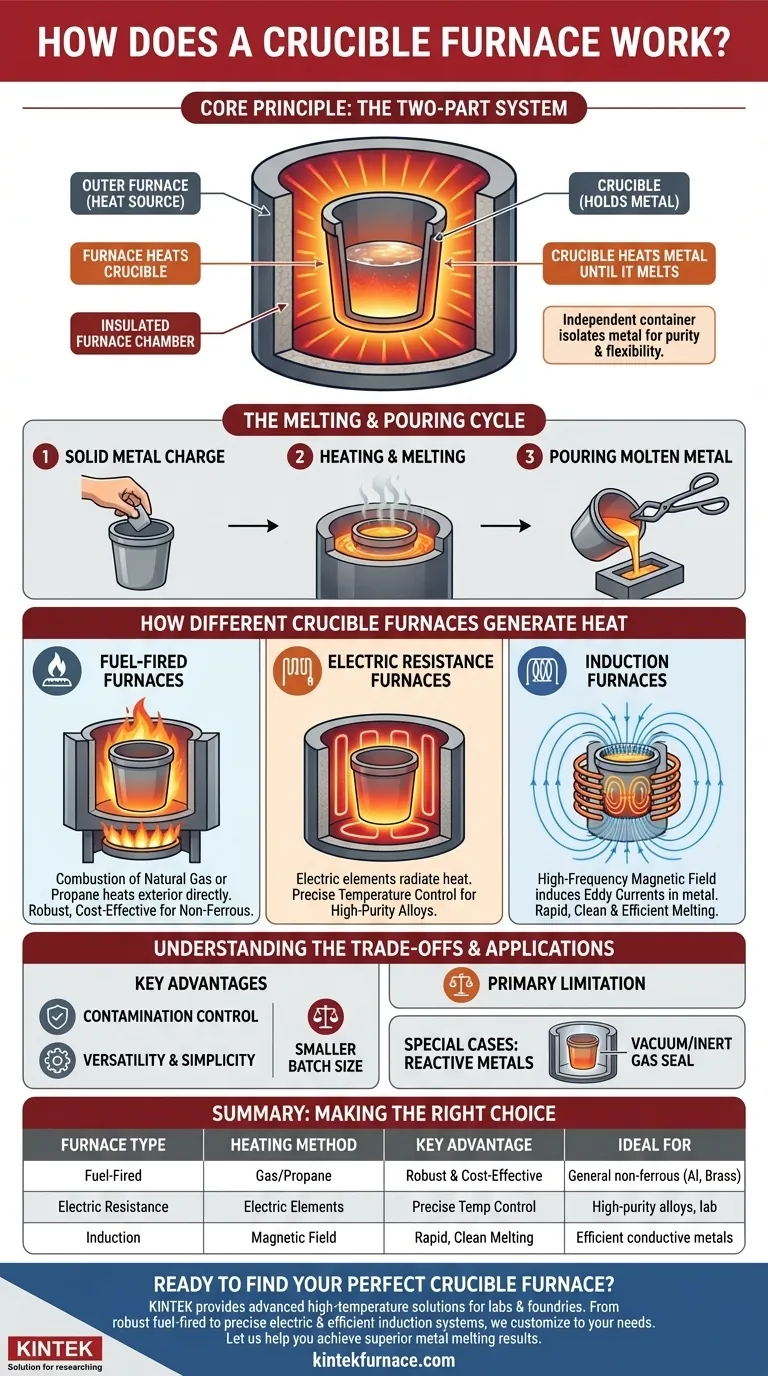

At its core, a crucible furnace works by using a two-part system: an outer furnace that generates heat and an inner, removable pot called a crucible that holds the metal. The furnace heats the crucible, and the crucible, in turn, transfers that heat to the metal inside it until it melts. Once the metal is liquid, the crucible is removed from the furnace for pouring.

The defining principle of a crucible furnace is the use of an independent container—the crucible—to isolate the metal. This simple concept provides flexibility and prevents contamination, while the specific method of heating (fuel, electric resistance, or induction) determines the furnace's efficiency, precision, and application.

The Core Components and Process

A crucible furnace's operation is straightforward, revolving around two primary components working in sequence. Understanding each part clarifies the entire process.

The Crucible: The Heart of the Furnace

The crucible is a pot made from a refractory material, meaning it can withstand extreme temperatures without melting or degrading. Common materials include graphite or high-grade fire clay.

Its primary job is to act as a clean, durable container for the metal charge. This isolates the molten metal from the furnace's internal atmosphere and heating elements, which is critical for maintaining metal purity.

The Furnace Chamber: The Heat Source

The furnace itself is an insulated chamber designed to generate and contain intense heat. This heat is then transferred to the crucible placed inside.

The method used to generate this heat is the main differentiator between types of crucible furnaces.

The Melting and Pouring Cycle

The process is simple and cyclical. First, solid metal is placed into the crucible. The crucible is then placed inside the furnace chamber.

The furnace is activated, heating the crucible and melting the metal inside. Once the metal reaches the desired temperature, the crucible is lifted out using tongs or a mechanical manipulator and the molten metal is poured into a mold.

How Different Crucible Furnaces Generate Heat

While the crucible concept is constant, the technology used to deliver heat varies significantly. This choice impacts everything from heating speed and precision to operational cost.

Fuel-Fired Furnaces

These are the traditional workhorses, using the combustion of fuel like natural gas or propane to generate heat. The flame directly heats the exterior of the crucible.

This method is robust and common for melting non-ferrous metals like aluminum, brass, and bronze in small foundries and workshops.

Electric Resistance Furnaces

These furnaces operate much like a kiln or a high-temperature oven. They use electric heating elements arranged inside the insulated chamber.

When powered, these elements glow red-hot, transferring heat to the crucible primarily through radiation. This method offers excellent and highly programmable temperature control, making it ideal for applications requiring thermal precision.

Induction Furnaces

This is a more modern and highly efficient method. An induction coil is wrapped around a non-conductive crucible (or a conductive one, like graphite).

When a high-frequency alternating current is passed through the coil, it creates a powerful, fluctuating magnetic field. This field induces electrical eddy currents directly within the conductive metal charge, causing it to heat up and melt rapidly due to its own electrical resistance. It is an exceptionally clean and fast way to melt metal.

Understanding the Trade-offs and Applications

The decision to use a crucible furnace, and which type, involves balancing its inherent advantages against its limitations.

Key Advantage: Contamination Control

Because the metal only ever touches the inert crucible, there is no contamination from combustion byproducts or the furnace lining. This is essential for producing high-quality alloys.

Key Advantage: Versatility and Simplicity

Crucible furnaces are ideal for smaller batch operations. The ability to melt a batch, pour it, and quickly start another with a different alloy provides significant flexibility. The process is relatively simple to manage.

Primary Limitation: Batch Size

Crucible furnaces are generally not used for the massive-scale production seen in the steel industry, where other furnace types are more efficient for melting tons of metal at once. They are best suited for batches measured in pounds or kilograms, not tons.

Special Cases: Reactive Metals

For metals like titanium that react aggressively with air when hot, the crucible concept is adapted. The entire crucible and induction coil assembly can be enclosed in a hermetically sealed chamber. This allows melting to occur in a vacuum or under an inert gas like argon, completely protecting the metal.

Making the Right Choice for Your Application

The best crucible furnace is the one that aligns with your specific material, quality requirements, and operational scale.

- If your primary focus is general-purpose, small-scale non-ferrous melting: A fuel-fired or simple electric resistance furnace is a cost-effective and reliable choice.

- If your primary focus is high-purity alloys or precise temperature control: An electric resistance furnace with a programmable controller offers superior accuracy.

- If your primary focus is rapid, clean, and efficient melting of conductive metals: An induction furnace is the modern, high-performance solution.

- If your primary focus is melting reactive metals like titanium: A specialized vacuum induction crucible furnace is the only suitable option.

Ultimately, the crucible furnace remains a foundational tool in metallurgy because its core principle of separation is both simple and profoundly effective.

Summary Table:

| Furnace Type | Heating Method | Key Advantage | Ideal For |

|---|---|---|---|

| Fuel-Fired | Gas/Propane Combustion | Robust & Cost-Effective | General non-ferrous metals (Al, Brass) |

| Electric Resistance | Electric Heating Elements | Precise Temperature Control | High-purity alloys, lab use |

| Induction | Magnetic Field (Eddy Currents) | Rapid, Clean Melting | Efficient melting of conductive metals |

Ready to Find Your Perfect Crucible Furnace?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and foundries with advanced high-temperature furnace solutions. Whether you need the robust simplicity of a fuel-fired furnace, the precise control of an electric model, or the high efficiency of an induction system, our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to meet your unique experimental and production requirements.

Let us help you achieve superior metal melting results. Contact our experts today for a personalized solution!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Induction Melting Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab