The primary purpose of using a forced-air drying oven at 100 °C is to execute a prolonged pre-drying phase for biomass precursors, such as soybean residue. This process is strictly aimed at the thorough removal of physically adsorbed water, which is critical for stabilizing the material before it undergoes chemical modification and high-temperature carbonization.

Core Takeaway Successful synthesis of Fe3O4@Fe-AC composites relies on eliminating moisture variables before processing begins. Proper pre-drying prevents structural failure during carbonization and ensures that all chemical ratios are calculated based on accurate, dry mass.

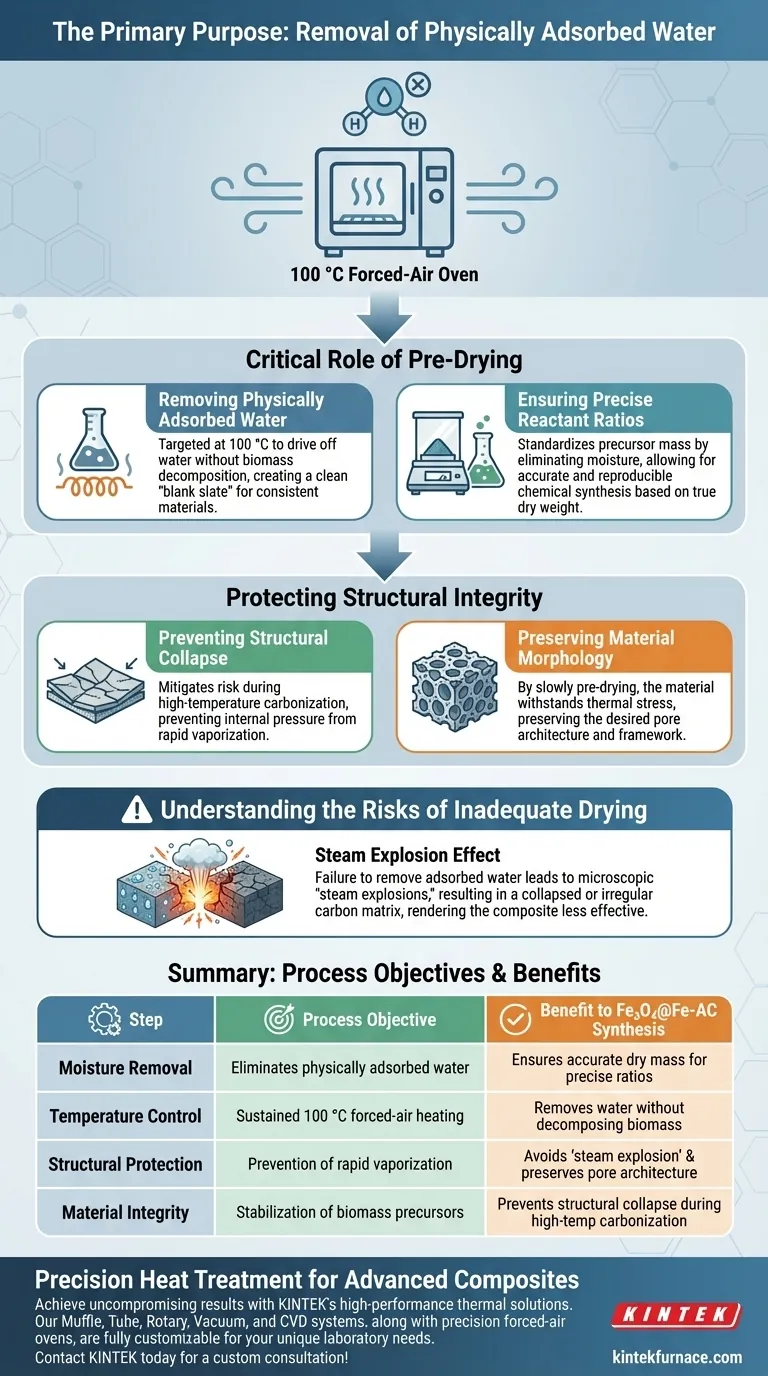

The Critical Role of Pre-Drying

Removing Physically Adsorbed Water

The specific setting of 100 °C is utilized to target physically adsorbed water trapped within the biomass structure.

At this temperature, water is effectively driven off without initiating the thermal decomposition of the organic biomass itself. This creates a "clean slate" for the material, ensuring that the starting material is consistent.

Ensuring Precise Reactant Ratios

One of the most immediate benefits of this drying step is the standardization of the precursor's mass.

If the biomass contains varying amounts of moisture, it is impossible to calculate precise reactant ratios for subsequent chemical modifications. By removing the water, you ensure that the weight you measure is the actual biomass, allowing for accurate and reproducible chemical synthesis.

Protecting Structural Integrity

Preventing Structural Collapse

The most significant long-term risk of skipping this step occurs during the later stages of synthesis, specifically high-temperature carbonization.

If water remains trapped within the biomass when it is subjected to high heat, it will undergo rapid vaporization. This sudden expansion of steam can exert internal pressure that destroys the material's pores and framework.

Preserving Material Morphology

By pre-drying the material slowly at 100 °C, you mitigate the risk of this violent phase change.

This creates a stable precursor that can withstand the thermal stress of carbonization without suffering from structural collapse, thereby preserving the desired architecture of the final composite.

Understanding the Risks of Inadequate Drying

The "Steam Explosion" Effect

It is vital to understand that water is not inert during high-temperature processing; it is a potential structural hazard.

Failing to remove adsorbed water leads to a phenomenon similar to a microscopic steam explosion inside the material. This results in a collapsed or irregular carbon matrix, rendering the Fe3O4@Fe-AC composite less effective for its intended application.

Ensuring Success in Composite Synthesis

To maximize the quality of your final material, you must view the drying oven not as a storage step, but as a critical synthesis parameter.

- If your primary focus is Chemical Accuracy: Ensure prolonged drying to establish a true dry weight, which guarantees that your dopants and modifiers are added in the exact stoichiometric ratios required.

- If your primary focus is Structural Stability: Prioritize this step to eliminate internal moisture, preventing the pore collapse that occurs when wet biomass is exposed to rapid heating.

A disciplined approach to pre-drying is the single most effective way to ensure both the chemical precision and physical durability of your final composite.

Summary Table:

| Step | Process Objective | Benefit to Fe3O4@Fe-AC Synthesis |

|---|---|---|

| Moisture Removal | Eliminates physically adsorbed water | Ensures accurate dry mass for precise reactant ratios |

| Temperature Control | Sustained 100 °C forced-air heating | Removes water without decomposing the organic biomass |

| Structural Protection | Prevention of rapid vaporization | Avoids "steam explosion" and preserves pore architecture |

| Material Integrity | Stabilization of biomass precursors | Prevents structural collapse during high-temperature carbonization |

Precision Heat Treatment for Advanced Composites

Achieve uncompromising results in your synthesis with KINTEK’s high-performance thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as precision forced-air ovens.

Whether you are preparing Fe3O4@Fe-AC composites or conducting complex high-temp carbonization, our systems are fully customizable to meet your unique laboratory needs. Ensure structural integrity and chemical accuracy in every batch.

Ready to elevate your material research? Contact KINTEK today for a custom consultation!

Visual Guide

References

- Ka Chun Li, Xijun Hu. Fe<sub>3</sub>O<sub>4</sub>@Fe Core–Shell Okara-Derived Activated Carbon for Superior Polysulfide Control in Lithium–Sulfur Batteries. DOI: 10.1021/acs.jpcc.5c02606

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does the precise control of heating rates affect sewage sludge biochar? Master Stability & Metal Stabilization

- What role does high-vacuum thermal evaporation equipment play in CsPbBr3 detectors? Optimize Electrode Fabrication

- What are the typical applications for drying ovens? Essential Uses in Labs and Industry

- How does a temperature-programmed system influence molybdenum carbide formation? Expert Catalyst Synthesis Guide

- What gas is used in a graphite furnace? A Guide to Argon vs. Nitrogen for Optimal Analysis

- Why is a vacuum or inert gas environment required during ball milling? Protect Your Nanocrystalline Alloy Purity

- Why must nickel-based bimetallic catalyst precursors be treated in a blast drying oven? Prevent Structural Failure

- How is a mass spectrometer utilized in TPO tests for catalysts? Enhance Your Material Characterization