At their core, batch furnaces are essential because they provide an unparalleled level of process control and operational flexibility. Unlike continuous systems designed for mass production, batch furnaces allow for the meticulous heat treatment of individual loads, making them indispensable for applications where material integrity and precision are the primary goals.

While continuous furnaces excel at high-volume, repetitive tasks, the true value of a batch furnace lies in its ability to execute highly specific, customizable thermal cycles. This makes it the definitive choice for research, prototyping, and the production of high-value components where quality cannot be compromised.

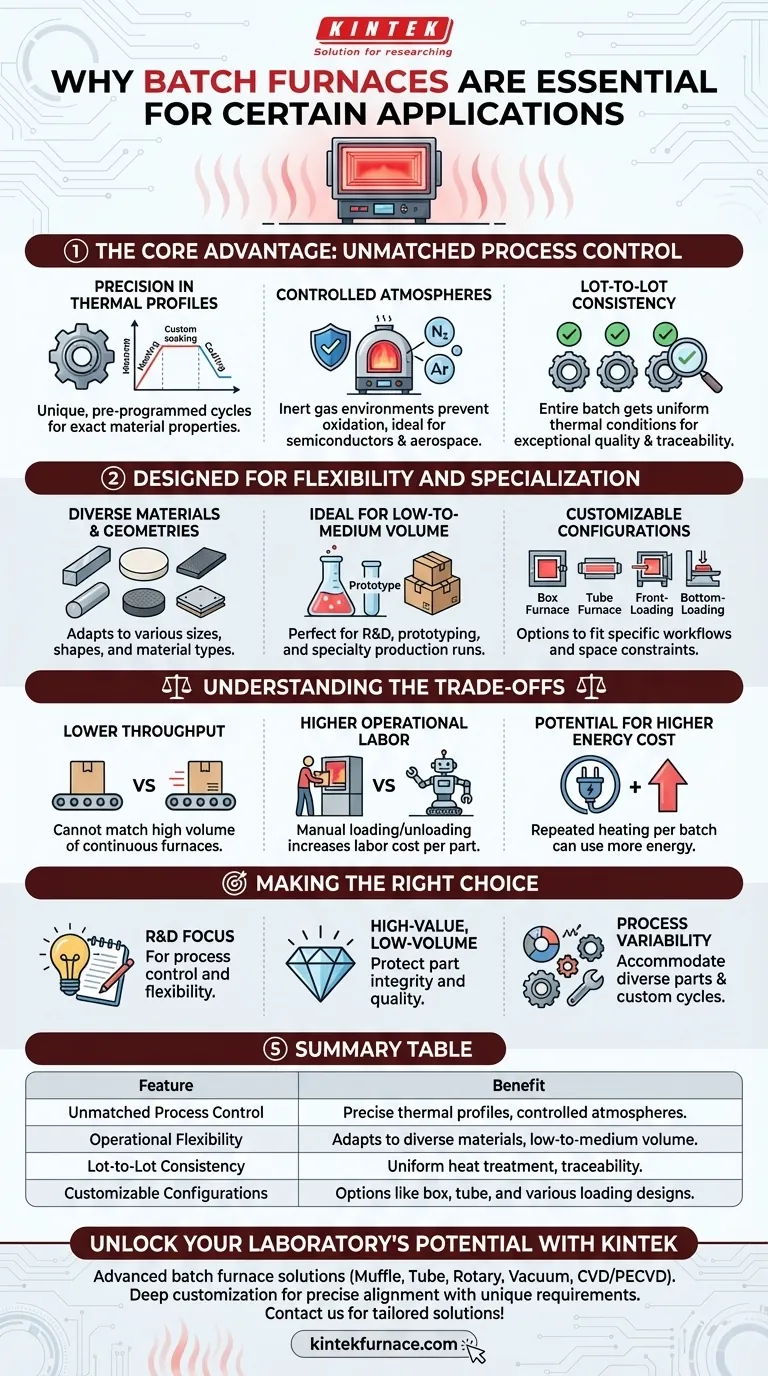

The Core Advantage: Unmatched Process Control

The defining characteristic of a batch furnace is the ability to manage every variable of the heat treatment cycle for a single, contained load. This provides a level of precision that is difficult to achieve in other systems.

Precision in Thermal Profiles

Each batch can be subjected to a unique, pre-programmed thermal profile. This includes complex steps for heating, soaking at a specific temperature, and controlled cooling, ensuring the material achieves the exact desired metallurgical or physical properties.

Controlled Atmospheres for Material Integrity

Many advanced applications require processing in a specific environment. Batch furnaces, particularly retort-style designs, excel at creating and maintaining controlled atmospheres of inert gases to prevent oxidation and contamination. This is critical for industries like semiconductors and aerospace.

Ensuring Lot-to-Lot Consistency

Because the entire load is processed as a single unit, every part within the batch experiences virtually identical thermal conditions. This guarantees exceptional consistency and traceability, which is a requirement for many quality-critical sectors.

Designed for Flexibility and Specialization

Batch furnaces are not built for a single purpose; they are designed to adapt to a wide range of operational needs, making them a versatile asset.

Handling Diverse Materials and Geometries

A single batch furnace can be used to process a wide variety of part sizes, shapes, and materials, from metals and ceramics to advanced composites. This adaptability is invaluable for job shops or R&D labs that handle diverse projects.

Ideal for Low-to-Medium Volume Production

Their nature makes them perfectly suited for research, prototyping, and specialty production runs. You can run one cycle for a single prototype or multiple cycles for a small production order with equal efficiency.

Customizable Physical Configurations

Batch furnaces come in numerous forms to suit the application, including box furnaces, tube furnaces, and designs with front-loading or bottom-loading mechanisms. This allows facilities to select a furnace that fits their specific workflow and space constraints.

Understanding the Trade-offs

To make an informed decision, it's crucial to recognize the inherent limitations of a batch processing model. Objectivity requires acknowledging where they do not excel.

Lower Throughput vs. Continuous Furnaces

The most significant trade-off is production volume. By design, batch furnaces cannot match the high throughput of a continuous furnace, which processes parts in an uninterrupted flow.

Higher Operational Labor

Each cycle requires manual or robotic loading and unloading of the furnace. This can result in higher labor costs per part compared to a more automated continuous system.

Potential for Higher Per-Part Energy Cost

While modern units are highly efficient, repeatedly heating the furnace for each new batch can consume more energy per part than a continuous furnace that is held at a constant operating temperature for long periods.

Making the Right Choice for Your Goal

Selecting the correct furnace technology comes down to a clear understanding of your primary operational driver.

- If your primary focus is research and development: A batch furnace provides the process control and flexibility essential for experimenting with new materials and thermal profiles.

- If your primary focus is high-value, low-volume production: The superior control over atmosphere and temperature in a batch furnace protects part integrity and ensures final product quality.

- If your primary focus is process variability: A batch furnace is the ideal choice for accommodating a mix of different part types, materials, and custom heat treatment cycles.

By aligning the furnace's capabilities with your specific application, you can confidently invest in the right thermal processing technology.

Summary Table:

| Feature | Benefit |

|---|---|

| Unmatched Process Control | Enables precise thermal profiles and controlled atmospheres for material integrity. |

| Operational Flexibility | Adapts to diverse materials, geometries, and low-to-medium volume production. |

| Lot-to-Lot Consistency | Ensures uniform heat treatment and traceability for quality-critical applications. |

| Customizable Configurations | Offers options like box, tube, front-loading, or bottom-loading designs to fit specific needs. |

Unlock the full potential of your laboratory with KINTEK's advanced batch furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental requirements, enhancing process control and efficiency. Contact us today to discuss how our tailored solutions can elevate your heat treatment processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab