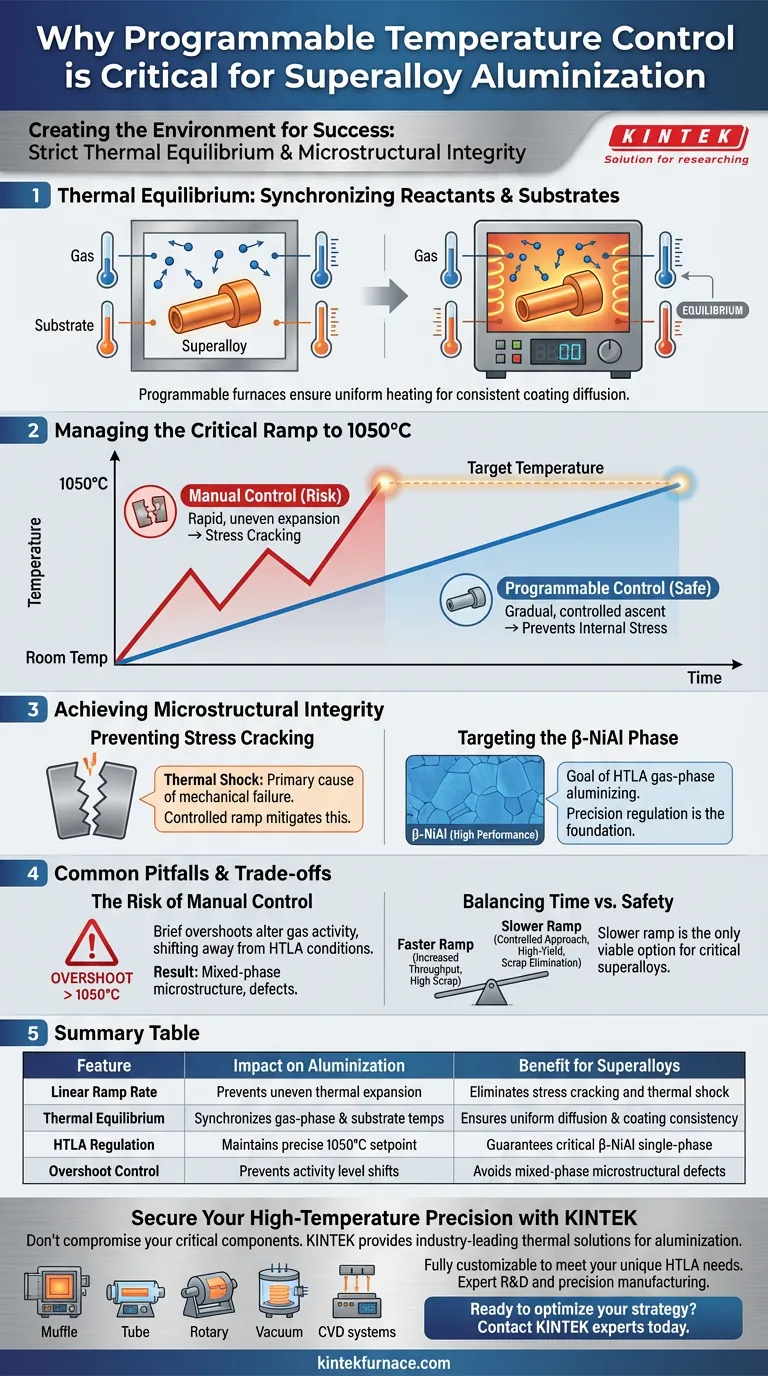

Programmable temperature control creates the necessary environment for successful aluminization by ensuring strict thermal equilibrium between the superalloy substrate and the gas-phase reactants. Without this precise management, particularly during the ramp from room temperature to 1050°C, the material becomes vulnerable to severe stress cracking and microstructural inconsistencies.

Precision heating is not just about reaching a setpoint; it is the defining mechanism that enables High-Temperature Low-Activity (HTLA) aluminizing. By synchronizing the temperature of the gas and the substrate, you secure the formation of the critical $\beta$-NiAl single-phase microstructure while eliminating the risks of thermal shock.

The Role of Thermal Equilibrium

Synchronizing Reactants and Substrates

The aluminization process relies on a delicate chemical interaction between the gas-phase reactants and the solid superalloy substrate.

For the coating to form correctly, these two distinct states of matter must be in thermal equilibrium. Programmable furnaces ensure that the gas and the metal heat at a synchronized rate, allowing for uniform diffusion.

Managing the Critical Ramp

The transition from room temperature to the target processing temperature of 1050°C is the most volatile phase of the process.

A programmable controller regulates this ascent with exactitude. By controlling the ramp rate, the furnace prevents the rapid, uneven expansion that creates internal stress within the component.

Achieving Microstructural Integrity

Preventing Stress Cracking

Thermal shock is the primary cause of mechanical failure during high-temperature treatments.

If the temperature rises too aggressively, the thermal gradient across the part causes stress cracking. Programmable control mitigates this by enforcing a gradual, consistent rise in temperature.

Targeting the $\beta$-NiAl Phase

The ultimate goal of this process is to achieve a specific microstructure known as the $\beta$-NiAl single-phase.

This structure is only attainable through High-Temperature Low-Activity (HTLA) gas-phase aluminizing. Precision temperature regulation is the "foundation" of HTLA, ensuring the coating develops the correct phase composition without unwanted byproducts.

Common Pitfalls and Trade-offs

The Risk of Manual Control

Attempting to manage this process without programmable steps often leads to "overshoot," where the temperature briefly exceeds 1050°C.

Even brief overshoots can alter the activity level of the gas, shifting the process away from HTLA conditions. This results in a mixed-phase microstructure that lacks the performance characteristics of pure $\beta$-NiAl.

Balancing Time vs. Safety

A programmable ramp is often slower than a direct heating method, which adds time to the production cycle.

However, the trade-off is non-negotiable. While a faster ramp might increase throughput, it drastically increases the scrap rate due to stress fractures, making the slower, controlled approach the only viable option for critical superalloys.

Optimizing Your Aluminization Strategy

To ensure high-yield results during superalloy aluminization, align your thermal profile with your specific material goals:

- If your primary focus is preventing mechanical failure: Prioritize a slow, linear ramp rate to 1050°C to minimize thermal shock and eliminate stress cracking.

- If your primary focus is coating performance: Ensure strict adherence to the HTLA temperature parameters to guarantee the formation of the $\beta$-NiAl single-phase microstructure.

Precision in temperature control is not merely a feature of the furnace; it is the engineering constraint that defines the quality of the final superalloy component.

Summary Table:

| Feature | Impact on Aluminization Process | Benefit for Superalloys |

|---|---|---|

| Linear Ramp Rate | Prevents uneven thermal expansion | Eliminates stress cracking and thermal shock |

| Thermal Equilibrium | Synchronizes gas-phase and substrate temps | Ensures uniform diffusion and coating consistency |

| HTLA Regulation | Maintains precise 1050°C setpoint | Guarantees critical $\beta$-NiAl single-phase |

| Overshoot Control | Prevents activity level shifts | Avoids mixed-phase microstructural defects |

Secure Your High-Temperature Precision with KINTEK

Don't let manual control or temperature overshoots compromise your critical superalloy components. KINTEK provides industry-leading thermal solutions designed for the rigorous demands of aluminization.

Backed by expert R&D and precision manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you require a benchtop unit or a high-capacity industrial furnace, our systems are fully customizable to meet your unique HTLA processing needs, ensuring the perfect $\beta$-NiAl microstructure every time.

Ready to optimize your aluminization strategy?

Contact KINTEK experts today to find the ideal programmable furnace for your laboratory or production line.

Visual Guide

References

- Effect of Ni-Based Superalloy on the Composition and Lifetime of Aluminide Coatings. DOI: 10.3390/ma18133138

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the significance of using high-temperature heating equipment to reach 1250°C for alloys? Stress Test Excellence

- What are the advantages of using a fixed-bed flow reactor? Precision Tools for Ammonia Decomposition Catalytic Activity

- How does first-order Padé approximation address technical challenges in electric furnace temperature regulation models?

- What role do high-temp furnaces play in co-firing SOFCs? Master Ceramic Densification and Sintering

- What heat treatment conditions are required for SDSS2507 solution treatment? Achieve Precise 1100°C Thermal Profiles

- Why is a vacuum drying oven necessary for MPCF@VG@SiNDs/C granulation? Ensure Framework Stability and Prevent Oxidation

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What role does a laboratory oven play in the drying phase of Co–Mg catalyst precursors? Ensuring Component Uniformity