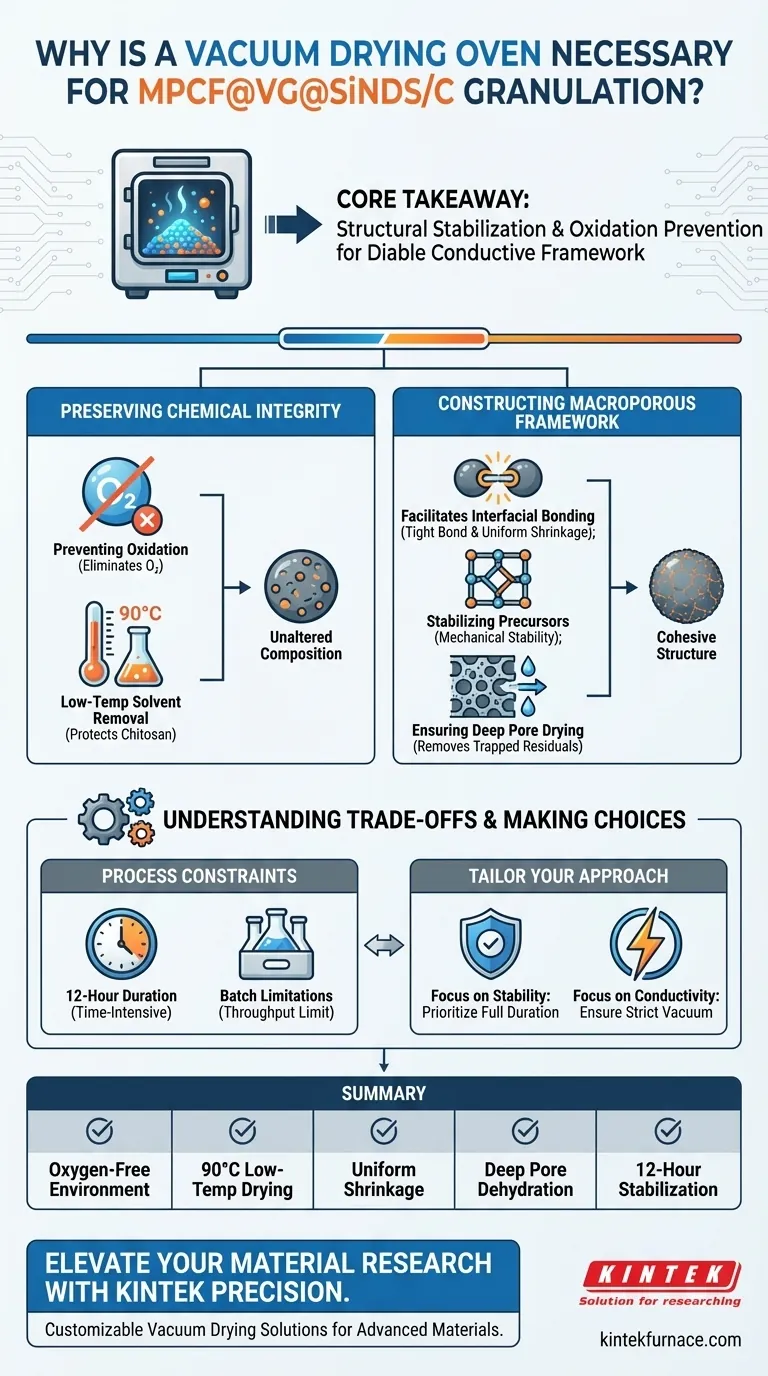

The use of a vacuum drying oven is a non-negotiable step in ensuring the structural and chemical integrity of MPCF@VG@SiNDs/C granules. By processing chitosan and functional composite slurries at a controlled 90 °C for 12 hours, the oven removes solvents efficiently while completely preventing material oxidation. This precise dehydration creates a tight, necessary bond between organic precursors and nanodots, establishing the foundation for a stable macroporous conductive framework.

Core Takeaway: Vacuum drying is not merely about moisture removal; it is a structural stabilization process that prevents oxidation and facilitates the critical interfacial bonding required to build a durable, high-performance conductive framework.

Preserving Chemical Integrity

To achieve high performance in MPCF@VG@SiNDs/C materials, the chemical composition must remain unaltered during the drying phase.

Preventing Oxidation

The primary function of the vacuum oven is to eliminate oxygen during the heating process. Functional composite materials and nanodots are highly susceptible to oxidation when exposed to air at elevated temperatures.

Low-Temperature Solvent Removal

Vacuum environments lower the boiling point of solvents. This allows for efficient drying at 90 °C, a temperature that effectively removes moisture without thermally degrading the sensitive organic components like chitosan.

Constructing the Macroporous Framework

The granulation process is not just about drying; it is about setting the physical structure of the material prior to carbonization.

Facilitating Interfacial Bonding

A specific advantage of vacuum drying is the promotion of a "tight bond" between organic precursors and nanodots. As solvents evaporate under vacuum, the chitosan matrix shrinks uniformly around the functional particles.

Stabilizing the Precursors

This bonding process is critical for mechanical stability. It ensures that the organic precursors and nanodots are locked into a cohesive structure, which is a prerequisite for constructing a stable macroporous conductive framework.

Ensuring Deep Pore Drying

While surface drying is simple, the complex structure of these materials can trap solvents deep within microscopic pores. The vacuum environment forces these residuals out, ensuring the material is thoroughly dehydrated from the inside out.

Understanding the Trade-offs

While vacuum drying is essential for quality, it introduces specific process constraints that must be managed.

Process Duration

The process is time-intensive, requiring a 12-hour cycle at 90 °C. Attempting to rush this process by increasing temperature or vacuum pressure too quickly can lead to structural defects or incomplete bonding.

Batch Limitations

Unlike continuous airflow drying, vacuum drying is typically a batch process. This limits throughput and requires careful scheduling to maintain production flow without creating bottlenecks.

Making the Right Choice for Your Goal

To maximize the quality of your MPCF@VG@SiNDs/C granules, tailor your drying approach to your specific performance metrics.

- If your primary focus is Structural Stability: Prioritize the full 12-hour duration to guarantee that the bond between organic precursors and nanodots is fully established.

- If your primary focus is Conductivity and Purity: Ensure strict vacuum adherence to prevent even trace oxidation, which can compromise the conductive network of the nanodots.

Precise control over the drying environment is the difference between a loose aggregate and a high-performance conductive framework.

Summary Table:

| Feature | Impact on MPCF@VG@SiNDs/C Material |

|---|---|

| Oxygen-Free Environment | Prevents oxidation of sensitive nanodots and functional composites. |

| 90 °C Vacuum Drying | Lowers solvent boiling points to protect organic precursors from thermal degradation. |

| Uniform Shrinkage | Promotes tight interfacial bonding between chitosan and nanodots. |

| Deep Pore Dehydration | Removes trapped residuals from complex macroporous structures. |

| 12-Hour Cycle | Ensures full structural stabilization and mechanical integrity. |

Elevate Your Material Research with KINTEK Precision

Don't let oxidation or structural defects compromise your high-performance conductive frameworks. KINTEK provides industry-leading vacuum drying solutions specifically designed for the delicate processing of advanced materials like MPCF@VG@SiNDs/C.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique laboratory or production needs. Ensure your organic precursors and nanodots achieve the perfect bond with our stable, high-precision thermal equipment.

Ready to optimize your granulation process? Contact our laboratory specialists today to find the ideal furnace configuration for your research.

Visual Guide

References

- Zhenwei Li, Jie Yu. Macroporous Directed and Interconnected Carbon Architectures Endow Amorphous Silicon Nanodots as Low-Strain and Fast-Charging Anode for Lithium-Ion Batteries. DOI: 10.1007/s40820-023-01308-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Induction Melting Furnace

People Also Ask

- What experimental conditions do physical property measurement systems provide for TaAs2? Explore Cryogenic Transport

- Why is a laboratory blast drying oven necessary for Ni-TiN catalysts? Ensure Precision in Precursor Treatment

- What is the basic principle of a sintering furnace? Transform Powder into Dense, Strong Components

- What role do high-temp furnaces play in co-firing SOFCs? Master Ceramic Densification and Sintering

- What role does Iodine (I2) play as a transport agent in CVT for FexTaSe2? Unlock Efficient Single Crystal Growth

- What is the function of the annealing furnace? Strategically Control Material Properties for Reliability

- What advantages does AlMe2iPrO (DMAI) offer over Trimethylaluminum (TMA)? Achieve Superior Area Selectivity

- Why is a vacuum sealing process necessary for the synthesis of TaAs2 single crystals? Ensuring Purity in CVT Method