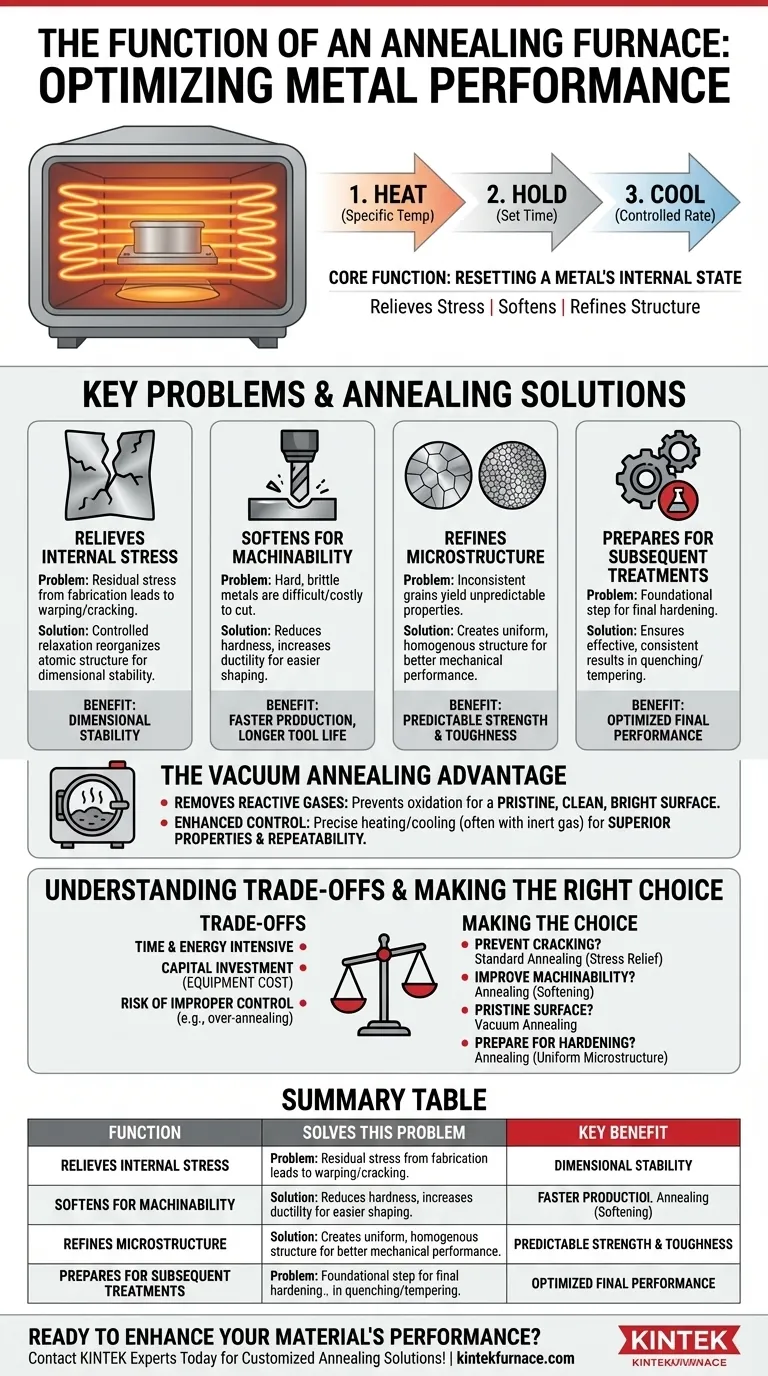

At its core, an annealing furnace is a tool for resetting a metal's internal state. It is a specialized oven that heats a metal to a specific temperature, holds it there for a set time, and then cools it at a controlled rate. This process relieves internal stresses, softens the metal, refines its internal structure, and prepares it for subsequent manufacturing steps.

While often seen as just a "softening" process, annealing is a strategic engineering step. Its primary purpose is to correct the structural defects introduced by prior manufacturing and prepare the material for optimal performance in its final application.

The Core Problems Annealing Solves

The annealing process is not an arbitrary step; it is a precise solution to common problems that arise during metal fabrication.

Relieving Internal Stress

Processes like casting, forging, rolling, and welding create significant residual stress within a material's structure. This locked-in stress can cause the workpiece to warp, deform, or even crack over time or during later machining.

Annealing provides a controlled "relaxation" period, allowing the metal's atomic structure to reorganize into a lower-stress state, ensuring dimensional stability.

Softening for Machinability

Hard, brittle materials are difficult and expensive to cut, drill, or shape. Annealing reduces hardness and increases ductility, making the metal significantly easier to machine.

This not only speeds up production and reduces tool wear but also allows for the creation of more complex geometries.

Refining the Microstructure

A metal's mechanical properties, like strength and toughness, are dictated by its internal grain structure. Fabrication processes can create inconsistent, coarse, or undesirable grain structures.

Annealing refines these grains, creating a more uniform and homogenous microstructure. This directly translates to more predictable and improved mechanical performance.

Preparing for Subsequent Treatments

Annealing is often a foundational step for other heat treatments. For example, to properly harden a piece of steel through quenching, it must first have a uniform and fine-grained structure.

Annealing creates this ideal starting condition, ensuring the final hardening or tempering process is as effective and consistent as possible.

A Key Variation: The Vacuum Annealing Furnace

While traditional annealing occurs in air, a vacuum furnace performs the process in a near-total vacuum, offering distinct advantages for sensitive applications.

Why Use a Vacuum?

The primary reason for using a vacuum is to remove oxygen and other reactive gases from the environment. This completely prevents oxidation and other surface reactions from occurring during the high-temperature cycle.

The Benefit of a Pristine Surface

Because no oxidation occurs, parts emerge from a vacuum furnace with a bright, clean, and smooth surface. This often eliminates the need for post-processing steps like sandblasting or acid cleaning, saving time and reducing cost.

Enhanced Control and Purity

Vacuum furnaces offer exceptionally precise control over heating and cooling rates. Cooling is often achieved by backfilling the chamber with a high-purity inert gas, like argon or nitrogen.

This level of control results in superior material properties, minimal internal stress, and high process repeatability.

Understanding the Trade-offs

While powerful, annealing is a process with clear operational considerations that must be balanced against its benefits.

Time and Energy Consumption

The controlled, often slow, heating and cooling cycles inherent to annealing make it a time-consuming process. The energy required to maintain high temperatures for extended periods can also be a significant operational cost.

Cost of Equipment

Industrial annealing furnaces, particularly advanced systems like vacuum furnaces, represent a substantial capital investment. This cost must be justified by the required quality and performance of the final product.

The Risk of Improper Control

Annealing is not a "one size fits all" process. Using the wrong temperature, hold time, or cooling rate can be detrimental. For example, over-annealing can cause excessive grain growth, which can actually reduce the material's strength and toughness.

Making the Right Choice for Your Goal

Applying annealing effectively requires matching the process to the desired outcome.

- If your primary focus is preventing post-weld cracking or deformation: Standard annealing is essential for relieving residual stress in the fabricated part.

- If your primary focus is improving the machinability of a tough alloy: Annealing to soften the material is your most direct and effective solution.

- If your primary focus is a perfectly clean, bright surface on a sensitive material: A vacuum annealing furnace is the superior choice to prevent any surface oxidation.

- If your primary focus is preparing a part for a final hardening process: Annealing creates the uniform microstructure necessary for a consistent and effective final treatment.

Ultimately, leveraging an annealing furnace correctly is about strategically controlling a material's internal properties to ensure its reliability and performance.

Summary Table:

| Function | Solves This Problem | Key Benefit |

|---|---|---|

| Relieve Internal Stress | Warping/cracking from fabrication | Ensures dimensional stability |

| Softening (Increase Ductility) | Difficult machining of hard metals | Improves machinability, reduces tool wear |

| Refine Microstructure | Inconsistent material properties | Creates uniform, predictable performance |

| Prepare for Final Hardening | Ineffective heat treatment | Ensures consistent and optimal results |

Ready to enhance your material's performance and reliability?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced annealing solutions tailored to your unique needs. Whether you require a standard atmosphere furnace for stress relief or a high-purity vacuum furnace for oxidation-sensitive materials, our product line—including Muffle, Tube, Rotary, and Vacuum & Atmosphere Furnaces—is backed by deep customization capabilities.

Let us help you achieve superior material properties and process repeatability. Contact our experts today to discuss your specific application and get a customized solution!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- Why is a double-chamber device preferred over a standard electric furnace for sintering? Achieve Oxidation-Free Results