Choosing the right heat treatment furnace is a critical decision that directly impacts operational efficiency, product quality, and overall cost-effectiveness. Selecting a furnace is not merely about reaching a certain temperature; it's about matching the equipment's specific capabilities to the unique demands of your material and process. An inappropriate choice leads to wasted energy, reduced productivity, and results that fail to meet required specifications.

The core challenge is not just heating a material, but controlling a thermal process. The right furnace provides the precise control over temperature, atmosphere, and capacity necessary to achieve repeatable, high-quality results in either a flexible laboratory environment or a high-throughput industrial setting.

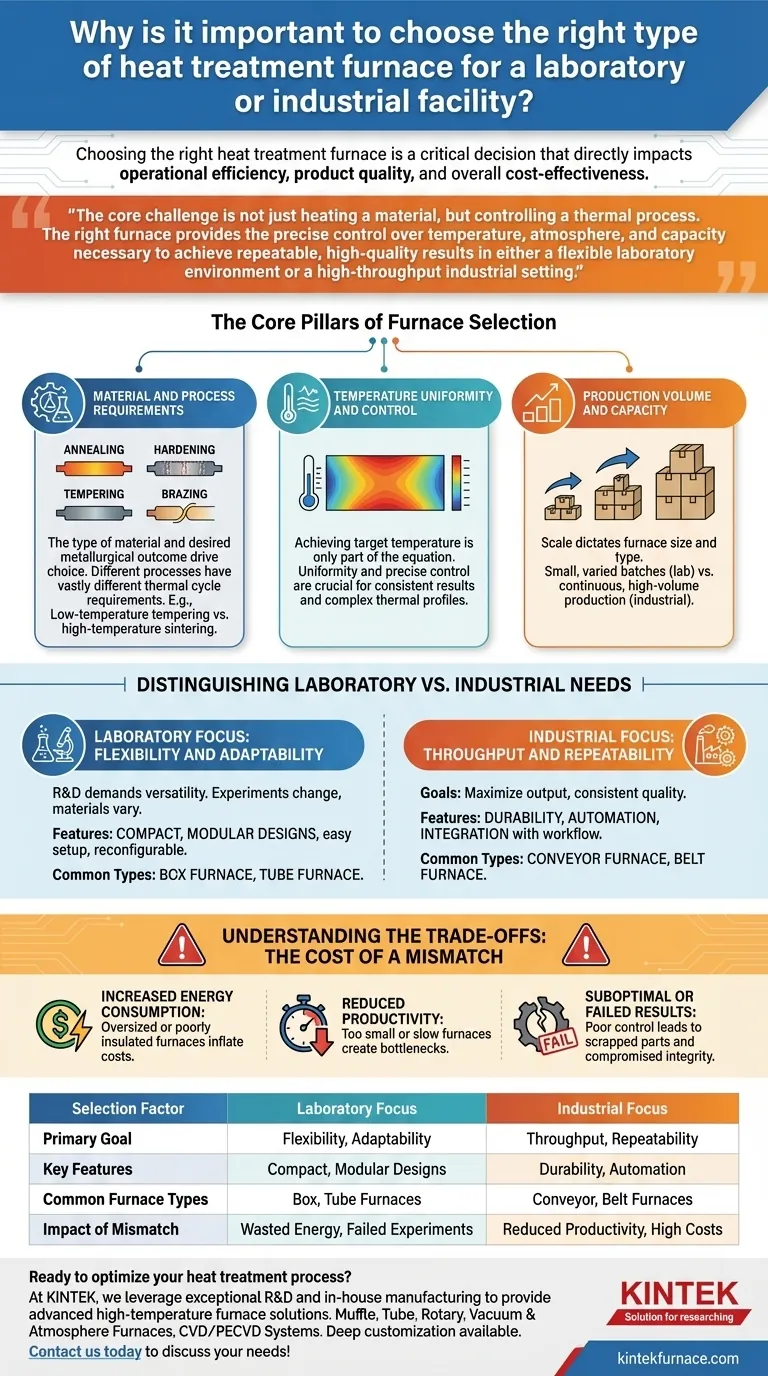

The Core Pillars of Furnace Selection

The decision process must be grounded in a clear understanding of your specific technical and operational requirements. These pillars form the foundation for a successful investment.

Material and Process Requirements

The type of material you are processing and the desired metallurgical outcome are the primary drivers of your choice. Different materials and heat treatment processes like annealing, hardening, tempering, or brazing have vastly different thermal cycle requirements.

A furnace designed for low-temperature tempering of steel, for example, is entirely unsuitable for high-temperature sintering of ceramics.

Temperature Uniformity and Control

Achieving the target temperature is only part of the equation. Temperature uniformity—ensuring the entire workload is at the same temperature—is crucial for consistent results.

Precise temperature control allows you to execute complex heating and cooling profiles accurately, which is essential for developing specific microstructures and material properties.

Production Volume and Capacity

The scale of your operation dictates the necessary size and type of furnace. A mismatch here creates significant inefficiency.

For small, varied batches typical of a laboratory, a box furnace or tube furnace is often ideal. For continuous, high-volume industrial production, a conveyor or belt furnace is necessary to keep pace with the production line.

Distinguishing Laboratory vs. Industrial Needs

While the core principles are the same, the priorities for laboratory and industrial applications are distinct.

The Laboratory Focus: Flexibility and Adaptability

Research and development environments demand versatility. Experiments change, materials vary, and processes are constantly being refined.

Therefore, laboratory furnaces often feature compact, modular designs. This allows for easy setup, reconfiguration, and adaptability to a wide range of tests while working within the budget constraints common to R&D departments.

The Industrial Focus: Throughput and Repeatability

In a production setting, the primary goals are maximizing output and ensuring every part meets the exact same quality standard. Consistency is paramount.

Industrial furnaces are built for durability, automation, and integration into a larger manufacturing workflow. The focus is on reliable, repeatable performance, cycle after cycle, to ensure high throughput and minimal downtime.

Understanding the Trade-offs: The Cost of a Mismatch

Selecting the wrong furnace is not a minor inconvenience; it has significant and costly consequences that ripple through your entire operation.

Increased Energy Consumption

An oversized furnace or one with poor insulation will consume far more energy than necessary to process a workload, leading to inflated operational costs. This is a constant and unnecessary drain on resources.

Reduced Productivity

A furnace that is too small for your production volume creates a bottleneck, slowing down the entire manufacturing process. Similarly, a furnace with slow heat-up or cool-down times can severely limit your daily throughput.

Suboptimal or Failed Results

This is the most critical failure. An incorrect furnace—whether due to poor temperature uniformity, inadequate atmosphere control, or an improper thermal cycle—can fail to produce the desired material properties. This leads directly to scrapped parts, wasted materials, and compromised product integrity.

Making the Right Choice for Your Goal

To select the correct furnace, you must first define your primary objective. Your goal will guide you to the right balance of features, capacity, and cost.

- If your primary focus is research and development: Prioritize flexible, compact, and modular furnaces that can adapt to a wide range of experimental needs.

- If your primary focus is high-volume industrial production: Select a durable furnace optimized for consistent throughput, repeatability, and integration with your production line.

- If your primary focus is cost-effectiveness: Carefully match the furnace's size, energy efficiency, and capabilities directly to your specific workload to avoid waste in both capital and operational spending.

Making an informed choice ensures your heat treatment process is a reliable asset, not an operational liability.

Summary Table:

| Selection Factor | Laboratory Focus | Industrial Focus |

|---|---|---|

| Primary Goal | Flexibility, Adaptability | Throughput, Repeatability |

| Key Features | Compact, Modular Designs | Durability, Automation |

| Common Furnace Types | Box, Tube Furnaces | Conveyor, Belt Furnaces |

| Impact of Mismatch | Wasted Energy, Failed Experiments | Reduced Productivity, High Costs |

Ready to optimize your heat treatment process? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to precisely meet your unique experimental or production requirements. Whether you're in a lab or industrial facility, we can help you achieve superior efficiency and quality. Contact us today to discuss how our furnaces can benefit your operation!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation