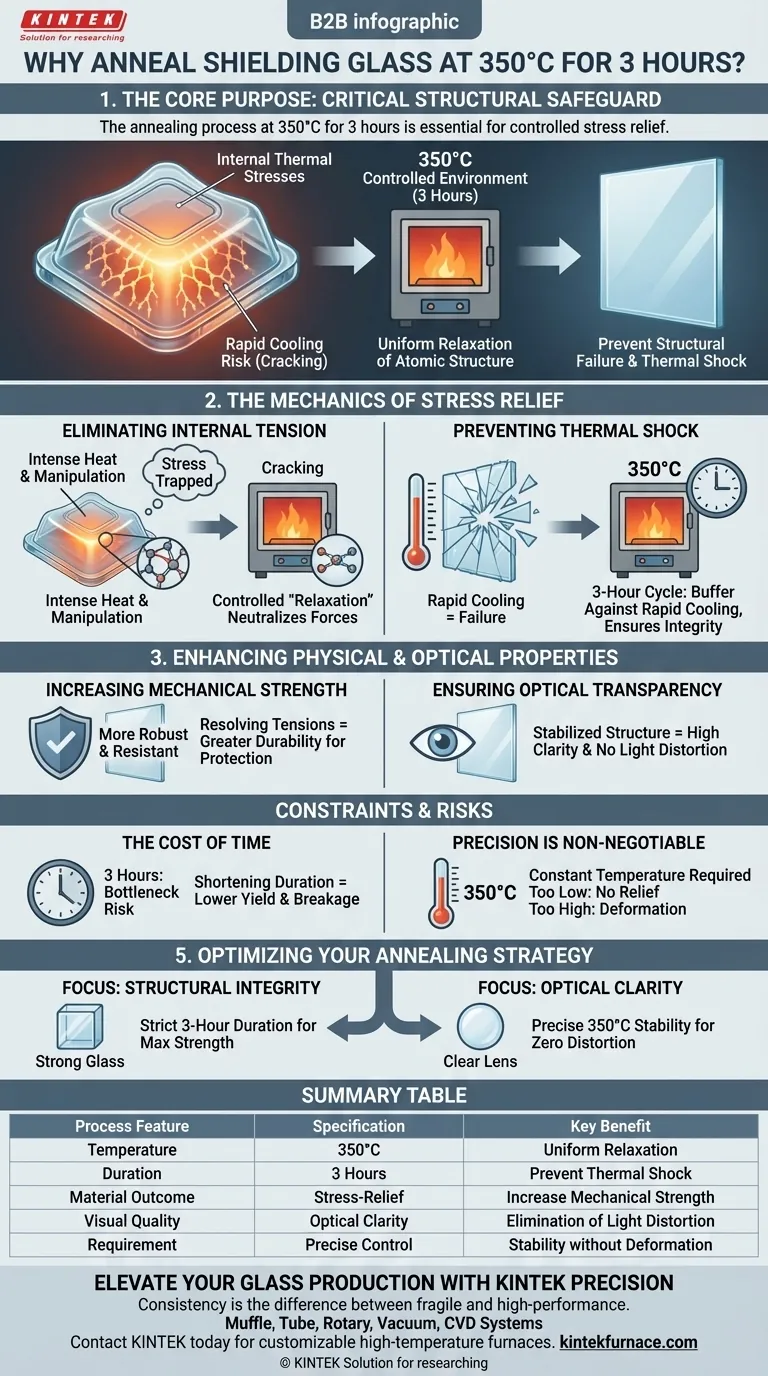

The annealing process is a critical structural safeguard. It is necessary to hold shielding glass at 350°C for three hours to allow internal thermal stresses to release slowly and uniformly. This specific thermal cycle prevents the catastrophic cracking associated with rapid cooling while locking in essential material properties.

The primary purpose of this 3-hour heat treatment is to prevent structural failure caused by thermal shock. By maintaining a precise 350°C environment, the glass relaxes its internal structure, ensuring both physical durability and high optical transparency.

The Mechanics of Stress Relief

Eliminating Internal Tension

During the molding process, glass is subjected to intense heat and manipulation. This creates significant internal thermal stresses within the material's atomic structure.

If the glass is allowed to cool naturally or unevenly, these stresses become trapped. The annealing furnace provides a controlled environment where the glass can "relax," effectively neutralizing these internal forces.

Preventing Thermal Shock

Glass is highly susceptible to failure when subjected to rapid temperature changes. The most immediate risk of bypassing the annealing stage is cracking.

The three-hour cycle at 350°C acts as a buffer. It prevents the rapid cooling that leads to fractures, ensuring the structural integrity of the newly molded sample remains intact.

Enhancing Physical and Optical Properties

Increasing Mechanical Strength

Beyond simply preventing cracks, annealing actively improves the quality of the final product. A key benefit of this process is a significant increase in mechanical strength.

By resolving internal tensions, the glass becomes more robust and resistant to external pressures. This is vital for shielding applications where protective capability is paramount.

Ensuring Optical Transparency

Shielding glass must often provide clear visibility alongside protection. Internal stress can distort light or create structural inconsistencies that mar clarity.

The annealing process ensures high optical transparency. By stabilizing the material structure, the glass maintains the clarity required for its intended functional use.

Understanding the Constraints and Risks

The Cost of Time

The most obvious trade-off is the impact on production throughput. Dedicating three hours to a static heating cycle creates a potential bottleneck in manufacturing.

However, attempting to shorten this duration often results in a lower yield due to breakage or hidden structural weaknesses.

Precision is Non-Negotiable

The effectiveness of this process relies entirely on temperature stability. The furnace must provide a precise constant temperature.

Fluctuations around the 350°C mark can render the process ineffective. If the temperature drops too low, stress is not relieved; if it spikes too high, the glass may deform.

Optimizing Your Annealing Strategy

To get the most out of your shielding glass production, consider your specific performance goals when managing the annealing phase.

- If your primary focus is Structural Integrity: Adhere strictly to the full three-hour duration to maximize mechanical strength and eliminate fracture risks.

- If your primary focus is Optical Clarity: Ensure the furnace temperature remains precisely constant at 350°C to prevent distortions that affect transparency.

Consistency in the annealing phase is the single most important factor in transitioning from a molded shape to a reliable, high-performance safety product.

Summary Table:

| Process Feature | Specification | Key Benefit |

|---|---|---|

| Temperature | 350°C | Uniform relaxation of internal atomic structure |

| Duration | 3 Hours | Prevention of thermal shock and spontaneous cracking |

| Material Outcome | Stress-Relief | Significant increase in mechanical strength and durability |

| Visual Quality | Optical Clarity | Elimination of light distortion for high-transparency |

| Requirement | Precise Control | Ensures stability without material deformation |

Elevate Your Glass Production with KINTEK Precision

Consistency in heat treatment is the difference between a fragile sample and a high-performance safety product. KINTEK provides the advanced thermal technology required to master delicate processes like glass annealing. Backed by expert R&D and world-class manufacturing, we offer high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your specific laboratory or industrial needs.

Don't let thermal stress compromise your yield. Contact KINTEK today to discover how our customizable high-temperature furnaces can optimize your annealing cycles and guarantee the structural integrity of your materials.

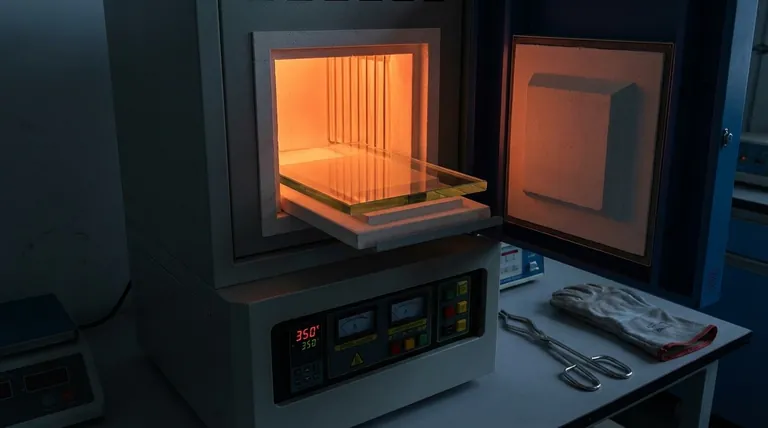

Visual Guide

References

- Mohamed Elsafi, Taha A. Hanafy. Experimental study of different oxides in B2O3–ZnO–BaO glass system for gamma-ray shielding. DOI: 10.1038/s41598-025-85230-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the applications of heat treatment furnaces in the aerospace industry? Enhance Component Performance for Extreme Conditions

- Why is a constant temperature oven required for CoCrFeNiMn alloy powders? Ensure Superior Defect-Free Deposition

- How does the orientation of glass within a tempering furnace affect quality? Optimize Optical and Physical Properties

- What is the importance of controlling gas flow rates during purging? Prevent Thermal Stress and Equipment Failure

- What is Physical Vapor Deposition (PVD)? Master Thin Film Coating for Enhanced Materials

- Why is dual heat treatment required for SnO2 nanoparticles? Optimize Oxidation for Superior Performance

- How does a precision carbon dioxide gas flow control system influence the precipitation of high-purity lithium carbonate?

- What role does a vacuum oven play in the post-treatment of nano-hydroxyapatite coatings? Ensure Crack-Free Integrity