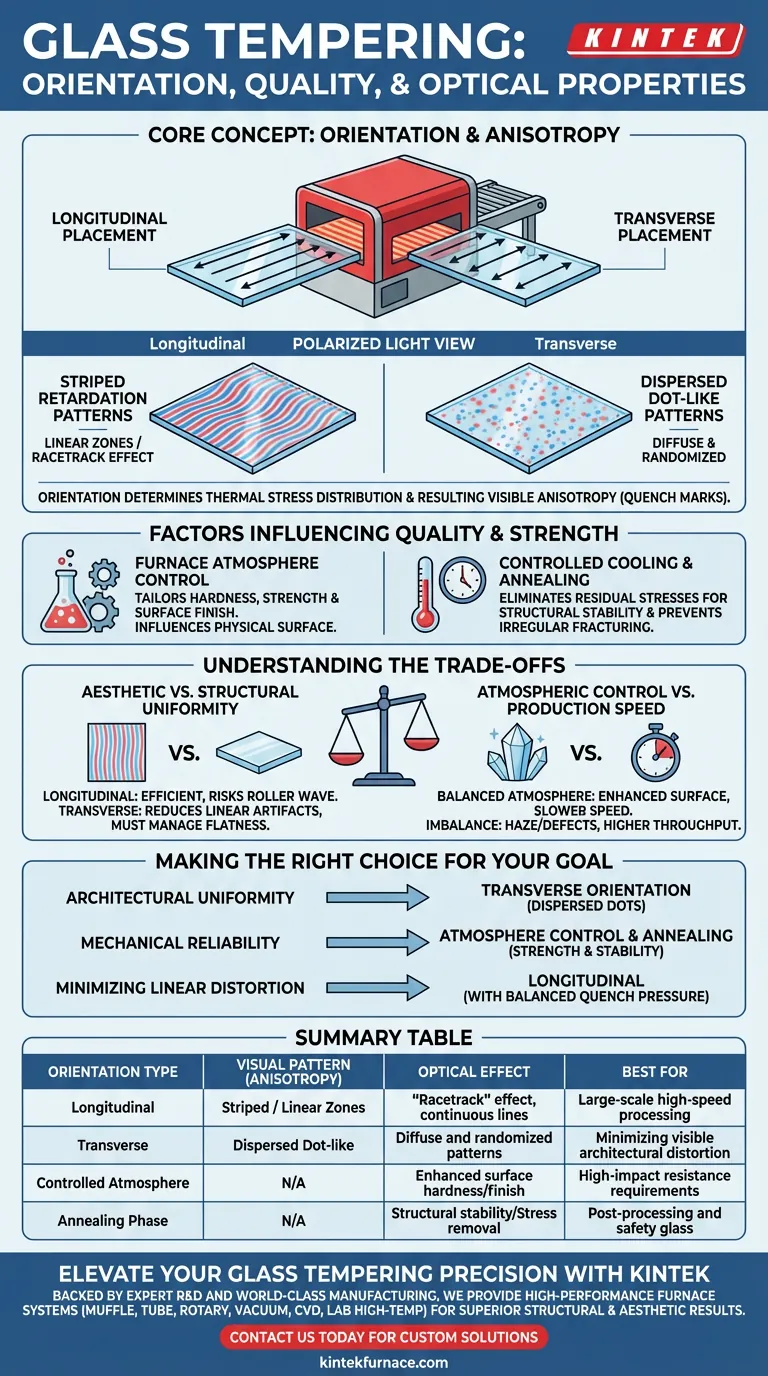

Glass orientation within a tempering furnace serves as the primary determinant for the visual patterns of optical anisotropy, commonly known as quench marks or "leopard spots." By choosing between longitudinal or transverse placement, manufacturers control whether the glass exhibits striped retardation patterns or dispersed dot-like patterns when viewed under polarized light.

The orientation of glass during the tempering process dictates the distribution of thermal stresses, directly shaping the aesthetic quality and optical uniformity of the finished product. Proper alignment is critical for minimizing visible interference patterns and ensuring structural reliability.

The Relationship Between Orientation and Optical Anisotropy

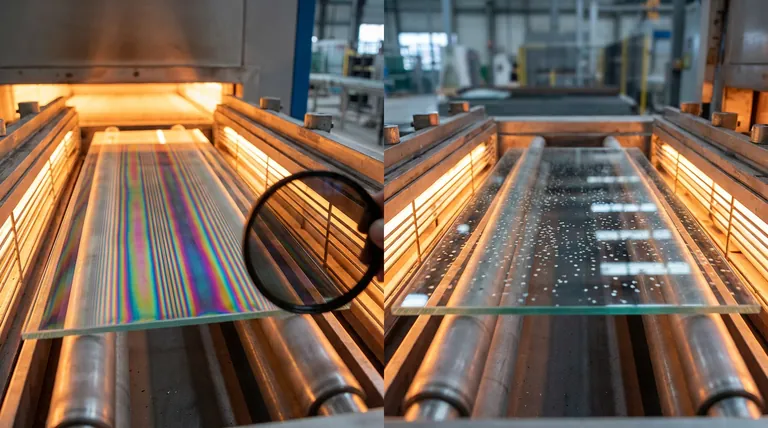

Longitudinal Placement and Striped Patterns

When glass is oriented longitudinally, the cooling air from the quench nozzles typically creates linear zones of stress. This results in striped retardation patterns that are most visible when the glass is viewed at an angle or through polarized lenses. These stripes follow the path of the glass through the furnace, creating a "racetrack" effect that can be prominent in large architectural facades.

Transverse Placement and Dot-like Patterns

Orienting the glass transversely changes how the cooling air interacts with the surface. This method produces dispersed dot-like patterns rather than continuous lines. These "dots" are often perceived as less distracting in certain lighting conditions, as they break up the visual continuity of the anisotropy, making the optical effects appear more diffuse and randomized.

The Role of Polarized Light

Optical anisotropy is not always visible to the naked eye under diffuse light. However, under polarized light conditions—such as light reflecting off water or specific sky conditions—the internal stress distribution becomes visible. The orientation chosen in the furnace determines the geometry of these visible patterns, which can significantly impact the perceived aesthetic quality of high-end installations.

Factors Influencing Material Quality and Strength

The Impact of Furnace Atmosphere

While orientation governs optics, the furnace atmosphere directly influences the physical surface of the glass. By precisely controlling the chemical environment within the furnace, manufacturers can tailor the hardness, strength, and surface finish of the material. This ensures that the glass meets specific mechanical requirements for its intended application, such as high-impact resistance.

Stress Management Through Controlled Cooling

Quality is further refined by managing internal thermal stresses. A controlled process, often involving holding the glass at approximately 480°C for one hour followed by slow cooling, eliminates residual stresses. This "annealing" phase ensures structural stability and prevents irregular fracturing, allowing the glass to be processed into smaller particles without failing due to stress concentrations.

Understanding the Trade-offs

Aesthetic vs. Structural Uniformity

Choosing an orientation is often a compromise between visual aesthetics and mechanical consistency. Longitudinal orientation may be more efficient for certain furnace layouts but risks creating highly visible "roller wave" distortions or stripes. Transverse orientation might reduce these linear artifacts but can introduce different cooling gradients that must be carefully managed to maintain surface flatness.

Atmospheric Control vs. Production Speed

Maintaining a specific furnace atmosphere to enhance surface hardness often requires slower production cycles. If the atmosphere is not perfectly balanced, the glass may suffer from surface haze or microscopic defects. Manufacturers must balance the need for a superior surface finish with the throughput requirements of the tempering line.

Making the Right Choice for Your Goal

To achieve the best results for your specific glass application, consider the following orientation and process strategies:

- If your primary focus is architectural uniformity: Use transverse orientation to produce dispersed dot patterns, which are generally less noticeable in large-scale glass assemblies.

- If your primary focus is mechanical reliability: Prioritize furnace atmosphere control and a rigorous annealing schedule to ensure the glass can withstand post-processing without fracturing.

- If your primary focus is minimizing linear distortion: Align the glass longitudinally but ensure that quench nozzle pressure is perfectly balanced to prevent deep "stripe" anisotropy.

The synergy between glass orientation and thermal control is what ultimately transforms a standard pane into a high-performance optical component.

Summary Table:

| Orientation Type | Visual Pattern (Anisotropy) | Optical Effect | Best For |

|---|---|---|---|

| Longitudinal | Striped / Linear Zones | "Racetrack" effect, continuous lines | Large-scale high-speed processing |

| Transverse | Dispersed Dot-like | Diffuse and randomized patterns | Minimizing visible architectural distortion |

| Controlled Atmosphere | N/A | Enhanced surface hardness/finish | High-impact resistance requirements |

| Annealing Phase | N/A | Structural stability/Stress removal | Post-processing and safety glass |

Elevate Your Glass Tempering Precision with KINTEK

Don't let optical anisotropy or surface defects compromise your product quality. At KINTEK, we understand that precision is non-negotiable. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your specific thermal processing needs.

Whether you are optimizing quench patterns or perfecting furnace atmosphere control, our team of experts is ready to help you achieve superior structural and aesthetic results.

Ready to refine your thermal process? Contact us today to find your custom solution.

Visual Guide

References

- Optical anisotropy effects in laminated tempered glass. DOI: 10.1007/s40940-024-00285-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How do microprocessor-controlled electric furnaces ensure the homogeneity of the Se80In5Te6Sb9 alloy?

- How do high-precision industrial furnaces contribute to thermal stability research in cement composites?

- Why is rapid water quenching necessary after thermal compression? Capture True Microstructures in Medium-Mn Steel

- How does rapid water cooling equipment contribute to the stability of the foaming agent in aluminum foam precursors?

- How do MFCs and Precursor Bottles Work in AP-ALD? Master Precision Vapor Draw for Atomic Coatings

- How does a blast drying oven affect the preparation of BN-C precursors? Optimize Structural Stability and Homogeneity

- What role does a laboratory drying oven play in the formation of polymer colloidal crystal templates? Mastering 3DOM Foundations

- Why is instantaneous heating required for N-GC-X catalyst synthesis? Achieve Superior 2D Nanosheet Morphology