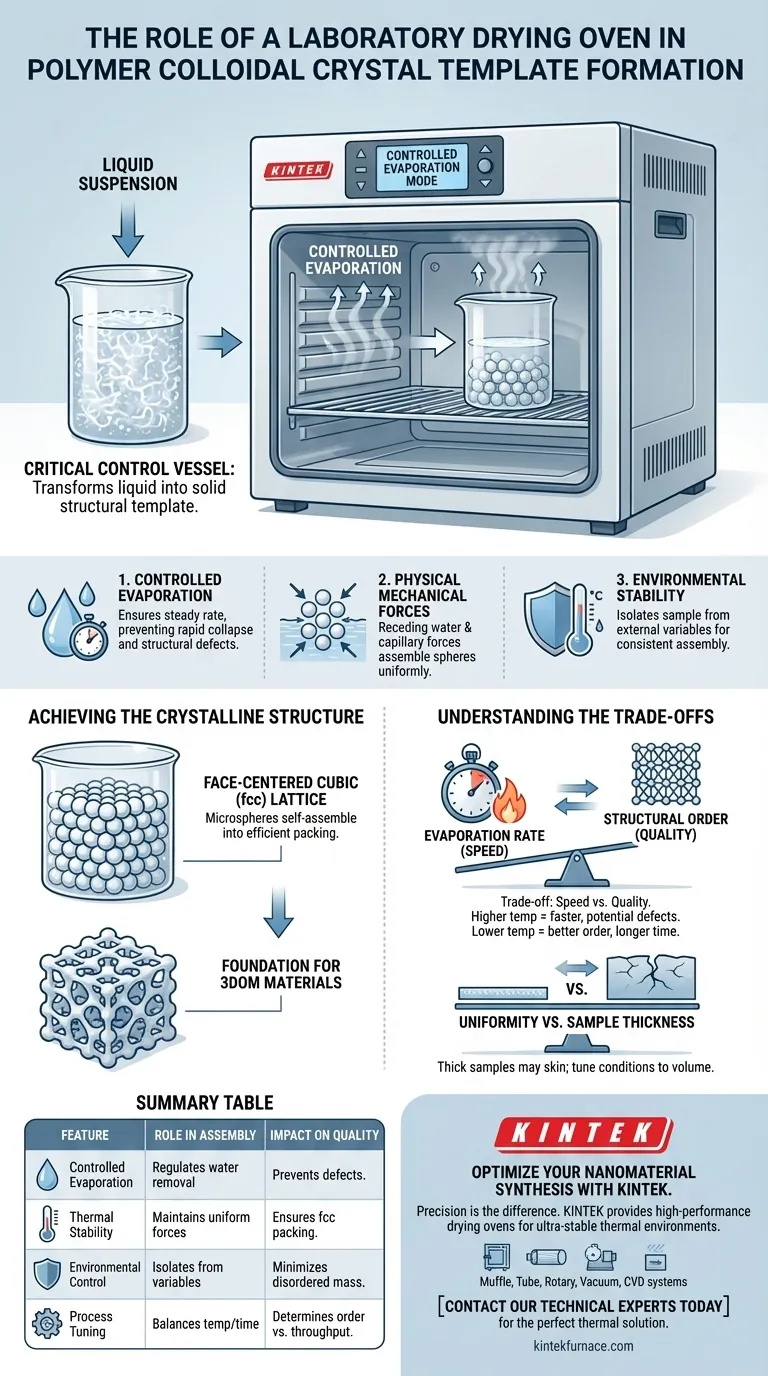

A laboratory drying oven acts as the critical control vessel for transforming liquid suspensions into solid structural templates. Its primary function is to facilitate the controlled evaporation of water from polymer microsphere suspensions. By maintaining a highly stable environment, the oven enables the microspheres to self-assemble into a precise crystalline structure, rather than drying into a disorganized mass.

The drying oven provides the stable thermal environment required for microspheres to organize via physical mechanical forces. This process results in a face-centered cubic (fcc) lattice, which serves as the essential foundation for synthesizing three-dimensional ordered macroporous (3DOM) materials.

The Mechanics of Colloidal Self-Assembly

To understand the oven's role, one must look beyond simple drying and understand the physics of assembly. The oven dictates the rate and uniformity of the phase transition.

Controlled Evaporation

The oven is not used to dry the material as quickly as possible. Instead, it ensures the water evaporates at a controlled, steady rate. This pacing is vital to prevent the rapid collapse of the suspension, which would lead to structural defects.

Utilizing Physical Mechanical Forces

As the water evaporates, physical mechanical forces come into play. The receding water line and capillary forces pull the polymer microspheres together. The oven's stable heat ensures these forces act uniformly across the sample.

Environmental Stability

Fluctuations in temperature or humidity can disrupt the assembly process. The laboratory drying oven maintains stable environmental conditions, isolating the sample from external variables that could cause uneven drying or cracking.

Achieving the Crystalline Structure

The ultimate goal of using the oven is to create a specific geometric arrangement of the polymer spheres.

The Face-Centered Cubic (fcc) Lattice

Under the stable conditions provided by the oven, the microspheres naturally arrange themselves into a face-centered cubic (fcc) lattice. This is a highly efficient packing structure where spheres are stacked in layers with minimal wasted space.

Building the Foundation for 3DOM

This ordered lattice is not the final product; it is a template. This structure acts as a "sacrificial mold." The high degree of order achieved in the oven is the essential foundation for creating Three-Dimensional Ordered Macroporous (3DOM) materials.

Understanding the Trade-offs

While the drying oven is essential, the process relies on a delicate balance of variables.

Evaporation Rate vs. Structural Order

There is a distinct trade-off between speed and quality. Higher temperatures increase evaporation speed but often lead to defects or cracks in the crystal lattice. Lower temperatures yield better ordering but significantly extend the processing time.

Uniformity vs. Sample Thickness

The oven applies heat externally. For very thick suspensions, the surface may dry faster than the interior (skinning), disrupting the fcc structure. The drying conditions must be tuned to match the volume of the suspension.

Making the Right Choice for Your Goal

When configuring a laboratory oven for polymer colloidal crystal templates, your settings should reflect your specific end-goals.

- If your primary focus is structural perfection: Prioritize lower temperatures and longer drying times to maximize the order of the fcc lattice.

- If your primary focus is process throughput: Increase the temperature incrementally, but monitor closely for the formation of cracks or disordered domains.

The laboratory drying oven is the instrument that bridges the gap between a chaotic liquid suspension and a precision-engineered nanomaterial template.

Summary Table:

| Feature | Role in Colloidal Assembly | Impact on Template Quality |

|---|---|---|

| Controlled Evaporation | Regulates water removal speed | Prevents structural defects and cracks |

| Thermal Stability | Maintains uniform mechanical forces | Ensures consistent face-centered cubic (fcc) packing |

| Environmental Control | Isolates sample from external variables | Minimizes disordered mass formation |

| Process Tuning | Balances temperature vs. drying time | Determines final structural order vs. throughput |

Optimize Your Nanomaterial Synthesis with KINTEK

Precision is the difference between a disordered mass and a perfect crystalline template. KINTEK provides high-performance laboratory drying ovens designed to deliver the ultra-stable thermal environments necessary for complex colloidal self-assembly.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized lab high-temp furnaces—all fully customizable to meet your unique research requirements. Whether you are developing 3DOM materials or advanced polymers, our equipment ensures the environmental stability your work demands.

Ready to elevate your material science? Contact our technical experts today to find the perfect thermal solution for your laboratory.

Visual Guide

References

- Sebastian Möhle, Peter Strasser. Iridium Oxide Inverse Opal Anodes with Tailored Porosity for Efficient PEM Electrolysis. DOI: 10.1002/adfm.202501261

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the primary purpose of an industrial blast drying oven for Si/HC-X? Optimize Biomass Material Pretreatment

- How does a temperature-controlled heating chamber ensure AEMWE testing accuracy? Unlock Reliable Electrolyzer Data

- Why are high frequencies used in induction heating? For Precise, Rapid Surface Heating

- Why is 800 °C necessary for NCNTs? Unlock Superior Conductivity and Ion Transport

- Why use 10% Carbon Monoxide in black liquor pyrolysis? Prevent sodium volatilization for superior char quality.

- How does a reactor system control chlorine sources in oxychlorination? Master Catalyst Regeneration Control

- What is the function of a solvothermal reactor during Ir-TiO2 synthesis? Enhance Material Doping and Morphology

- Why is high raw material purity essential for magnesium alloy research? Ensure Precise Thermodynamic Data Quality