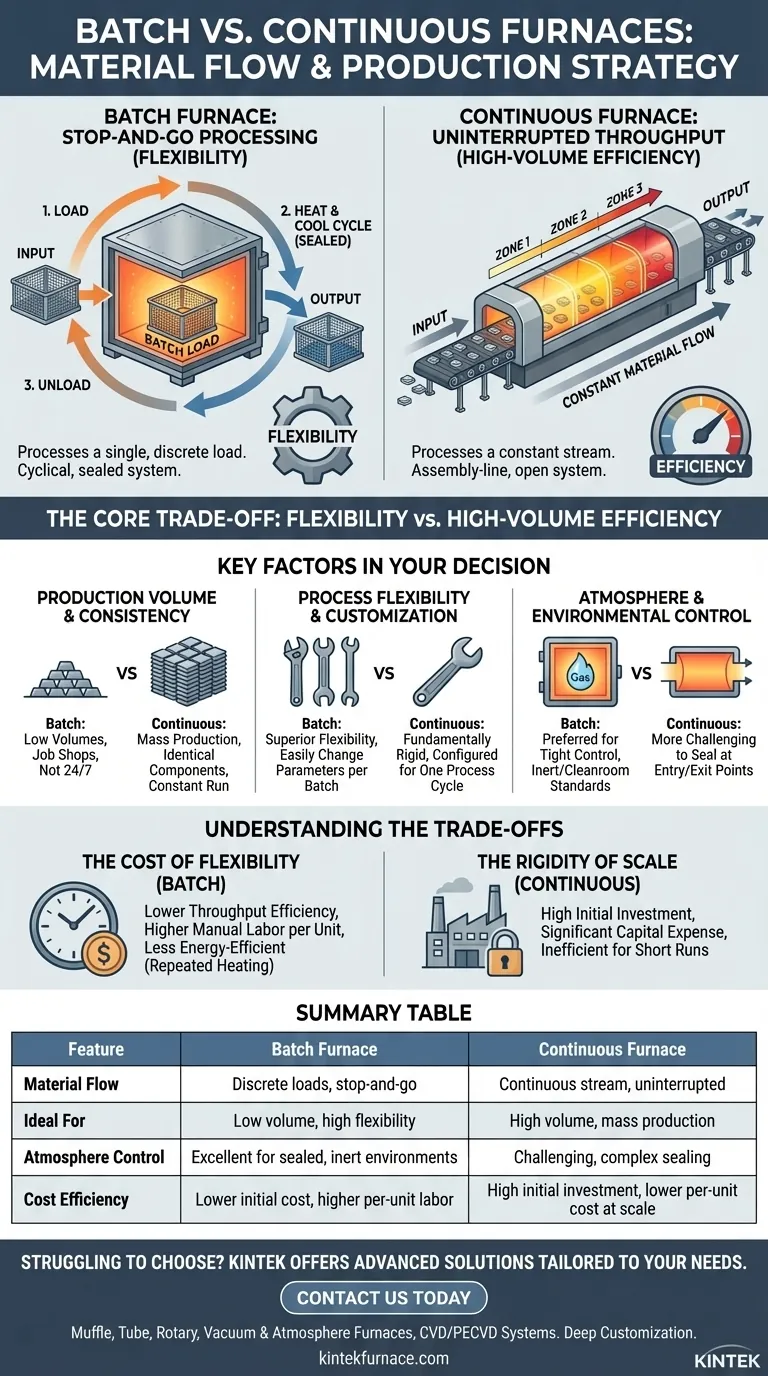

At a fundamental level, the difference between these two technologies lies in how they handle material flow. A batch furnace processes a single, discrete load of material at a time in a sealed chamber, completing a full heating and cooling cycle before it can be unloaded. In contrast, a continuous furnace processes a constant stream of material that moves through different temperature zones, entering one end and exiting the other without interruption.

The decision between a batch and continuous furnace is not about which is superior, but which model aligns with your production strategy. The core trade-off is between the flexibility of a batch furnace and the high-volume efficiency of a continuous furnace.

The Core Operational Difference: Process Flow

Understanding how material moves through each furnace is the key to grasping their distinct advantages and applications.

The Batch Furnace: Stop-and-Go Processing

A batch furnace operates on a distinct, cyclical basis. An entire lot, or "batch," of material is loaded into the furnace at once.

The chamber is then sealed, and the entire batch undergoes a specific heat treatment profile. Once the cycle is complete and the material has cooled, the furnace is opened and unloaded. This "stop-and-go" method makes it a sealed system, ideal for precise control.

The Continuous Furnace: Uninterrupted Throughput

A continuous furnace functions more like an assembly line. Material is constantly fed into one end of the furnace and moves through it, typically on a conveyor belt.

As the material travels, it passes through various zones set to different temperatures to achieve the desired treatment profile. Finished products are discharged continuously from the other end. This design is built for uninterrupted, high-volume operation.

Key Factors in Your Decision

Your choice will be driven by your specific production needs regarding volume, product mix, and environmental control.

Production Volume and Consistency

This is the most critical deciding factor. Continuous furnaces are designed for mass production of identical or very similar components. Their efficiency shines when they are run constantly to produce a high volume of a single product type.

Batch furnaces are better suited for lower volumes, job shops, or situations where production is not 24/7. They handle discrete quantities and can be shut down between cycles without significant efficiency loss.

Process Flexibility and Customization

Batch furnaces offer superior flexibility. Because each load is a separate event, you can easily change the temperature, time, and atmospheric parameters for every single batch. This is essential for industries that produce a wide variety of parts or require frequent process adjustments.

Continuous furnaces are fundamentally rigid. They are typically configured for one specific process cycle. Changing the temperature profile is a major undertaking, making them unsuitable for varied or customized production runs.

Atmosphere and Environmental Control

The sealed nature of a batch furnace makes it the preferred choice for processes requiring a tightly controlled inert atmosphere or cleanroom standards. The integrity of the sealed chamber prevents contamination and ensures atmospheric purity throughout the cycle.

While continuous furnaces can operate with controlled atmospheres, maintaining a perfect seal at the entry and exit points is more challenging and complex.

Understanding the Trade-offs

Neither furnace type is a perfect solution for all scenarios. You must weigh their inherent compromises.

The Cost of Flexibility (Batch Furnaces)

The primary trade-off for the flexibility of a batch furnace is lower throughput efficiency. The need to load, cool, and unload for every cycle increases manual labor requirements per unit.

Furthermore, repeatedly heating the furnace from a cooler state for each new batch is less energy-efficient compared to a continuous furnace that maintains a constant operating temperature.

The Rigidity of Scale (Continuous Furnaces)

The high efficiency of a continuous furnace comes at the cost of high initial investment and a lack of flexibility. These systems are a significant capital expense and are only cost-effective when their high capacity is fully utilized.

Running a continuous furnace for short production runs or with frequent changeovers is highly inefficient and negates its primary economic advantages. They demand a stable, high-volume production schedule to be justified.

Making the Right Choice for Your Goal

Select the furnace that directly serves your primary operational objective.

- If your primary focus is process flexibility and product customization: A batch furnace is the clear choice, allowing you to tailor each cycle to different product requirements.

- If your primary focus is high-volume, consistent mass production: A continuous furnace will deliver superior efficiency and lower per-unit labor costs once it is running at scale.

- If your primary focus is operating in a tightly controlled cleanroom or inert atmosphere: The sealed system of a batch furnace provides more reliable environmental control for sensitive processes.

Ultimately, understanding this core distinction between flexibility and scale empowers you to align your equipment choice with your strategic production goals.

Summary Table:

| Feature | Batch Furnace | Continuous Furnace |

|---|---|---|

| Material Flow | Discrete loads, stop-and-go | Continuous stream, uninterrupted |

| Ideal For | Low volume, high flexibility | High volume, mass production |

| Atmosphere Control | Excellent for sealed, inert environments | Challenging, complex sealing |

| Cost Efficiency | Lower initial cost, higher per-unit labor | High initial investment, lower per-unit cost at scale |

Struggling to choose the right furnace for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to enhance your production efficiency and achieve superior results with our expert solutions!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab

- What is a Quartz Tube Furnace and what is its primary function? Essential for Real-Time Material Observation

- What is the necessity of using vacuum-sealed quartz tubes? Ensuring Integrity in Ti-Cu Alloy Heat Treatment

- What technical requirements affect the external thermal strength of furnace tubes? Optimize for High-Temp Performance

- What happens to convective and radiative heat transfer effects at high furnace gas temperatures? Radiation Dominates for Superior Heating