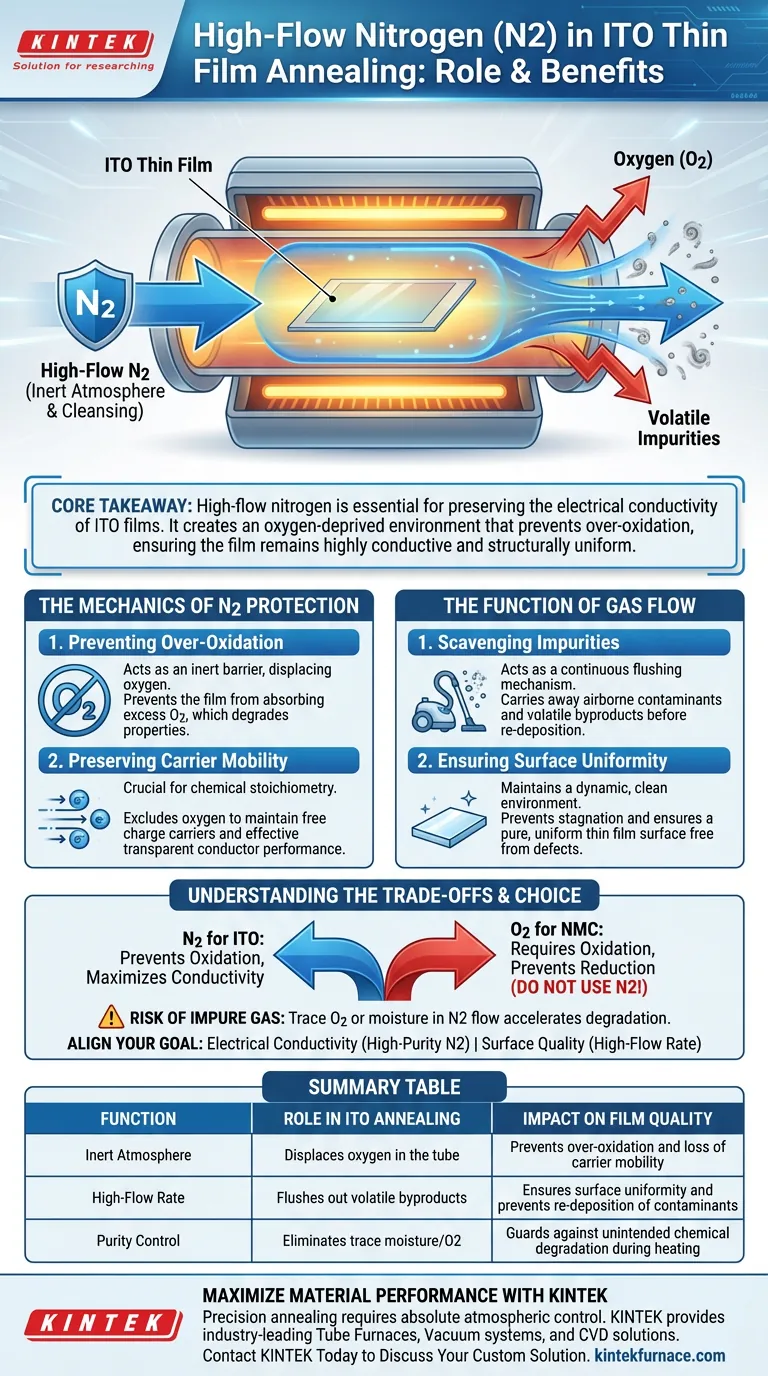

High-flow nitrogen (N2) serves as a critical protective and cleansing agent during the annealing of Indium Tin Oxide (ITO) thin films. Its primary function is to establish an inert atmosphere that prevents the film from absorbing excess oxygen, while simultaneously sweeping away volatile impurities released during the heating process.

Core Takeaway The introduction of high-flow nitrogen is essential for preserving the electrical conductivity of ITO films. It creates an oxygen-deprived environment that prevents over-oxidation—a reaction that degrades carrier mobility—ensuring the film remains highly conductive and structurally uniform.

The Mechanics of Nitrogen Protection

Preventing Over-Oxidation

The central challenge in annealing ITO is managing oxygen levels. At high temperatures, materials are highly reactive and prone to absorbing oxygen from the environment.

Nitrogen acts as an inert barrier, displacing oxygen within the tube furnace. This prevents the ITO film from over-oxidizing, a chemical change that fundamentally alters the material's properties.

Preserving Carrier Mobility

The electrical performance of ITO relies heavily on its specific chemical stoichiometry.

If the film absorbs too much oxygen (over-oxidation), the number of free charge carriers decreases. By excluding oxygen, nitrogen preserves the carrier mobility required for the film to function effectively as a transparent conductor.

The Function of Gas Flow

Scavenging Impurities

The "high-flow" aspect of the process is just as critical as the gas type. As the tube furnace heats up, the substrate and film may release trace impurities or volatile byproducts.

A continuous, high-volume flow of nitrogen acts as a flushing mechanism. It actively carries these airborne contaminants out of the heating zone before they can re-deposit onto the film.

Ensuring Surface Uniformity

By maintaining a constant flow, the environment inside the tube remains dynamic and clean.

This prevents the stagnation of gases and ensures that the thin film surface remains pure and uniform, free from defects caused by settling particulate matter or chemical contaminants.

Understanding the Trade-offs

Atmosphere Specificity

It is vital to understand that nitrogen annealing is specific to materials like ITO that require protection from oxidation.

Conversely, materials like NMC (Nickel Manganese Cobalt) thin films require an oxygen-rich environment to prevent reduction and maintain their chemical structure. Using nitrogen on an oxide-dependent material would strip it of necessary oxygen, while using oxygen on ITO would destroy its conductivity.

The Risk of Impure Gas

The effectiveness of this process relies entirely on the purity of the nitrogen source.

If the nitrogen supply contains even trace amounts of oxygen or moisture, the high-flow rate will inadvertently introduce these contaminants to the hot film, accelerating the very oxidation and degradation you are trying to prevent.

Making the Right Choice for Your Goal

To maximize the quality of your ITO films, align your furnace settings with your specific performance metrics:

- If your primary focus is Electrical Conductivity: Prioritize high-purity nitrogen flow to strictly limit oxygen exposure and maximize carrier mobility.

- If your primary focus is Surface Quality: Ensure the flow rate is sufficient to rapidly evacuate any volatile impurities generated during the ramp-up phase.

By controlling the atmosphere with high-flow nitrogen, you convert the tube furnace from a simple heater into a precision tool for chemical stabilization.

Summary Table:

| Function | Role in ITO Annealing | Impact on Film Quality |

|---|---|---|

| Inert Atmosphere | Displaces oxygen in the tube | Prevents over-oxidation and loss of carrier mobility |

| High-Flow Rate | Flushes out volatile byproducts | Ensures surface uniformity and prevents re-deposition of contaminants |

| Purity Control | Eliminates trace moisture/O2 | Guards against unintended chemical degradation during heating |

Maximize Your Material Performance with KINTEK

Precision annealing requires more than just heat; it requires absolute atmospheric control. KINTEK provides industry-leading Tube Furnaces, Vacuum systems, and CVD solutions designed to maintain the high-purity environments essential for ITO and semiconductor research.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique gas flow and temperature requirements. Whether you are optimizing electrical conductivity or surface uniformity, our technical team is ready to help you configure the perfect setup.

Ready to elevate your thin film research?

Contact KINTEK Today to Discuss Your Custom Solution

Visual Guide

References

- Hessa I. Alabdan, Tapas K. Mallick. Monolithic Use of Inert Gas for Highly Transparent and Conductive Indium Tin Oxide Thin Films. DOI: 10.3390/nano14070565

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the purpose of performing a final annealing treatment? Optimize Your Heterojunction Device Performance

- Why is XPS used to analyze manganese catalysts? Master Surface Valence States for Enhanced Reactivity

- Why is a planetary ball mill required for processing activated carbon? Achieve <30μm Particles for Superior Slurry

- What is the effect of 750°C to 950°C on activated carbon? Optimize Pore Structure & Surface Area

- What is the function of a high-temperature heat treatment furnace? Optimize AlCuCrFe2NiTi0.25 Alloy Properties

- Why is a 1:1 mixture of NaNO3 and KNO3 used in molten salt baths? Optimize Quenching Performance

- What is the significance of 1200 °C in ZrO2:Ti synthesis? Unlock Phase Purity in High-Performance Ceramics

- Why must ultra-high purity argon be continuously supplied for Aluminum-Silicon alloys? Ensure Viscosity Data Accuracy