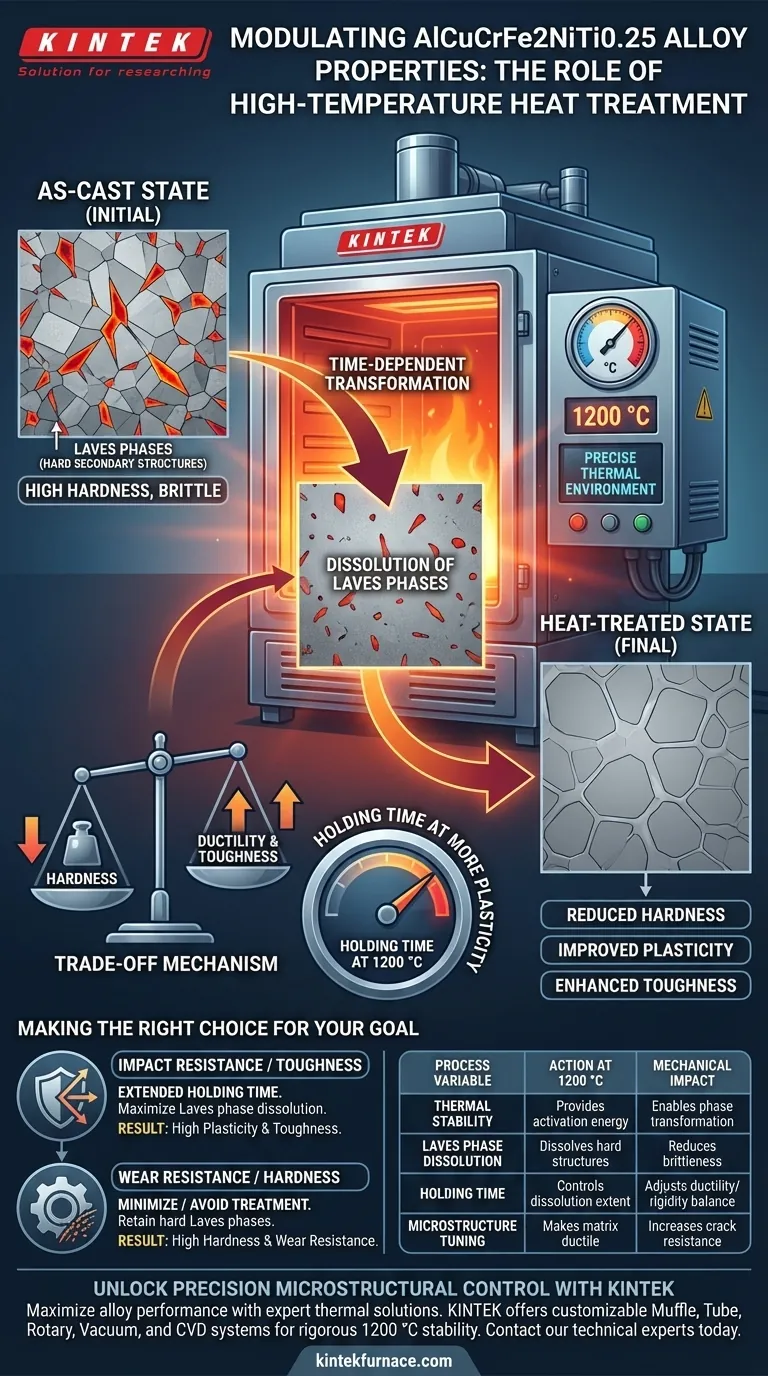

The function of a high-temperature heat treatment furnace for AlCuCrFe2NiTi0.25 alloys is to provide a precise, stable thermal environment at 1200 °C. This specific temperature range is critical for facilitating the gradual dissolution of hard Laves phases back into the alloy's matrix. By controlling the holding time within the furnace, engineers can modulate the material's microstructure to achieve a specific balance of mechanical properties.

Core Takeaway Heat treatment is a microstructural tuning tool, not just a heating process. By dissolving brittle secondary phases at 1200 °C, the furnace transforms the alloy from a state of high hardness to one of significantly improved plasticity and toughness.

The Mechanism of Property Modulation

Thermal Stability at 1200 °C

The primary role of the furnace is to maintain a consistent temperature of 1200 °C. This high thermal energy is necessary to activate the atomic diffusion required for phase transformation within the AlCuCrFe2NiTi0.25 alloy. Without this stable high-temperature environment, the microstructural changes required to alter the alloy's properties cannot occur efficiently.

Dissolution of Laves Phases

In its as-cast or initial state, this alloy contains "Laves phases." These are hard, secondary structures distributed throughout the material. The heat treatment furnace enables these second phases to gradually dissolve back into the primary matrix.

Time-Dependent Transformation

The extent of this dissolution is directly related to the "holding time" within the furnace. As the alloy remains at 1200 °C for longer periods, the dissolution of the hard phases becomes more complete. This allows for precise control over how much of the Laves phase remains in the final product.

Resulting Mechanical Changes

Reduction in Hardness

As the hard Laves phases dissolve, the overall hardness of the alloy decreases. The furnace essentially removes the internal "reinforcements" that contribute to extreme rigidity. This reduction is described as moderate, meaning the material retains structural integrity but loses its peak hardness.

Improvement in Plasticity

The most significant benefit of this heat treatment is the gain in plasticity. By removing the brittle second phases, the matrix becomes more ductile. This allows the material to deform under stress without fracturing immediately.

Enhancement of Toughness

Alongside plasticity, the alloy's toughness improves significantly. The heat-treated microstructure is better equipped to absorb energy and resist crack propagation, making the material more durable in dynamic applications.

Understanding the Trade-offs

Hardness vs. Ductility

It is vital to recognize that this process involves a direct trade-off. You are sacrificing hardness to gain toughness.

If an application relies heavily on surface hardness—for example, to resist abrasive wear—extended holding times in the furnace may be detrimental. The dissolution of the Laves phase removes the very structures that provide that hardness. Therefore, the furnace is not improving all properties, but rather shifting the balance toward ductility and away from brittleness.

Making the Right Choice for Your Goal

The use of a high-temperature furnace should be dictated by the specific mechanical requirements of your final component.

- If your primary focus is Impact Resistance/Toughness: Utilize the furnace at 1200 °C with sufficient holding time to dissolve the Laves phases, thereby maximizing plasticity.

- If your primary focus is Wear Resistance/Hardness: Minimize or avoid this specific heat treatment to retain the hard Laves phases within the matrix.

Ultimately, the furnace serves as a dial to adjust the alloy's ductility at the expense of its hardness.

Summary Table:

| Process Variable | Action at 1200 °C | Mechanical Impact |

|---|---|---|

| Thermal Stability | Provides activation energy for atomic diffusion | Enables microstructural phase transformation |

| Laves Phase Dissolution | Hard secondary structures dissolve into matrix | Reduces brittleness and peak hardness |

| Holding Time | Controls the extent of phase dissolution | Adjusts the balance between ductility and rigidity |

| Microstructure Tuning | Matrix becomes more ductile and uniform | Increases energy absorption and crack resistance |

Unlock Precision Microstructural Control with KINTEK

Maximize the performance of your advanced alloys with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous 1200 °C stability required for AlCuCrFe2NiTi0.25 alloys. Whether you need to maximize wear resistance or enhance impact toughness, our high-temp furnaces provide the precise thermal environment your research demands.

Ready to elevate your material properties? Contact our technical experts today to find the perfect furnace for your lab.

Visual Guide

References

- J.Y. Huang, Yunhai Su. The Effect of Solution Treatment on the Microstructure and Properties of AlCuCrFe2NiTi0.25 High-Entropy Hardfacing Alloy. DOI: 10.3390/cryst15020117

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the significance of using a 650°C annealing furnace for 42CrMo/Cr5 composite rollers after forging?

- What is the importance of providing technical documentation for high-temperature furnaces in multiple languages?

- What is the purpose of a high-temperature calcination furnace in Sol-Gel? Achieve High Purity and Crystallinity

- What is a sintering furnace used for? Fuse Powders into Dense, High-Performance Parts

- What information does TG-DTG provide for AASC? Analyze Thermal Stability and Hydration Products

- Why is a two-stage sintering process used for porous LATP? Master Structural Integrity and Porosity

- What is the function of coke and flux in lithium battery recycling? Optimize Metal Recovery and Slag Separation

- How does a reactor system control chlorine sources in oxychlorination? Master Catalyst Regeneration Control