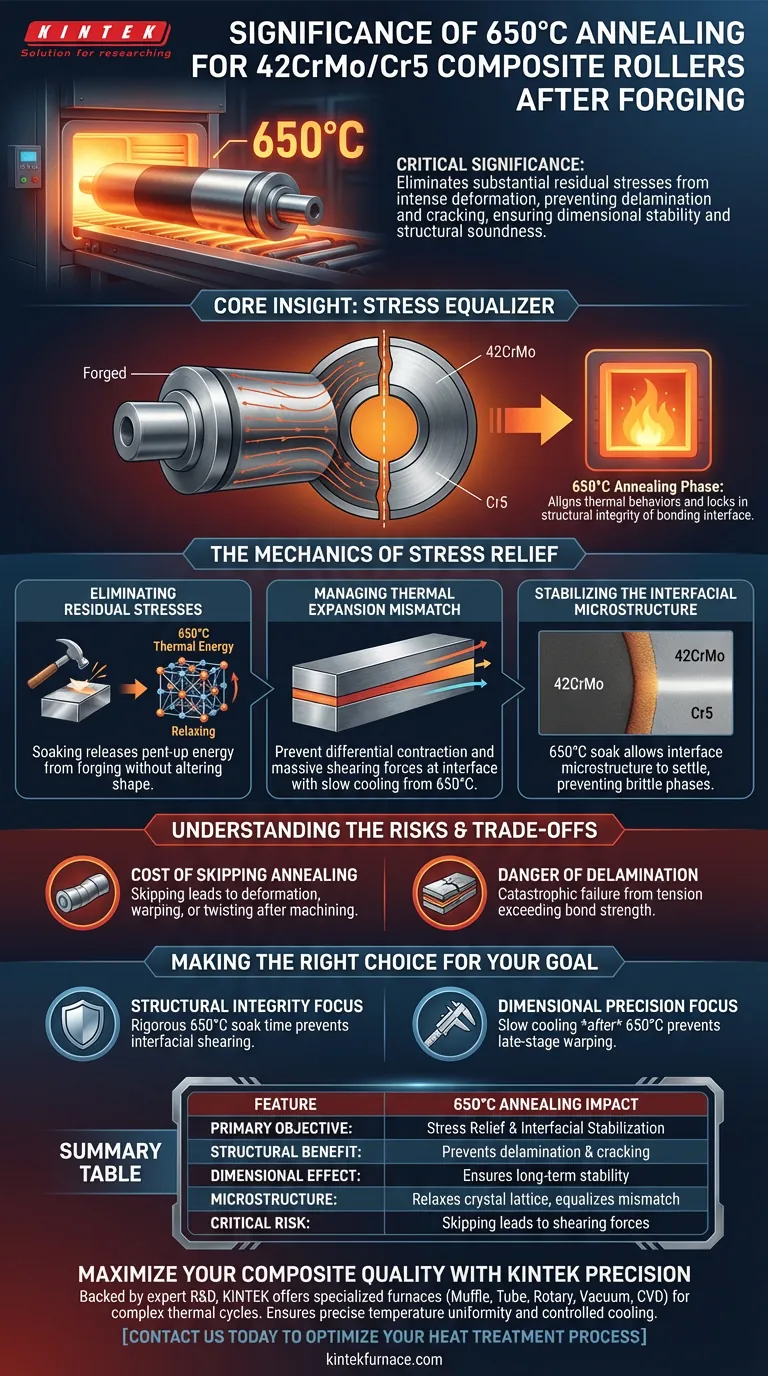

The critical significance of annealing 42CrMo/Cr5 composite rollers at 650°C lies in the elimination of substantial residual stresses created during the intense deformation of forging. By maintaining this constant temperature and following it with slow cooling, you prevent the composite materials from delaminating or cracking, thereby ensuring the component remains dimensionally stable and structurally sound.

Core Insight The forging process leaves composite metals in a highly stressed state with mismatched internal tensions. The 650°C annealing phase acts as a "stress equalizer," allowing the distinct metal layers to align their thermal behaviors and locking in the structural integrity of the bonding interface.

The Mechanics of Stress Relief

Eliminating Residual Stresses

Forging involves high-pressure mechanical deformation, often occurring after heating the billet to temperatures as high as 1150°C. This creates significant internal energy and tension within the molecular structure of the metal.

Soaking the roller at 650°C provides the thermal energy necessary for the crystal lattice to relax. This releases the pent-up energy from the forging process without altering the fundamental shape of the roller.

Managing Thermal Expansion Mismatch

The primary challenge with a composite roller (42CrMo combined with Cr5) is that these two distinct materials expand and contract at different rates.

If the roller cools uncontrolled from the forging temperature, one metal will contract faster than the other. This differential contraction generates massive shearing forces at the interface where the metals meet.

Stabilizing the Interfacial Microstructure

The 650°C soak is specifically targeted to stabilize the bond between the core and the composite layer.

By holding at this temperature, you allow the microstructure at the interface to settle into a stable equilibrium. This prevents the formation of brittle phases or micro-cracks that could propagate and cause failure under load.

Understanding the Risks and Trade-offs

The Cost of Skipping Annealing

It is often tempting to accelerate production by shortening the cooling cycle. However, in composite manufacturing, this is a fatal error.

Skipping or rushing the 650°C phase almost invariably results in deformation. The internal stresses will eventually relieve themselves, causing the roller to warp or twist after machining is complete.

The Danger of Delamination

The most severe risk is catastrophic cracking or delamination.

Without the equalization provided by the annealing furnace, the tension between the 42CrMo core and the Cr5 outer layer can exceed the bond strength. This causes the layers to separate, rendering the expensive forging a total loss.

Making the Right Choice for Your Goal

To ensure the longevity and performance of your composite rollers, you must prioritize the thermal cycle over throughput speed.

- If your primary focus is Structural Integrity: rigorous adherence to the 650°C soak time is non-negotiable to prevent interfacial shearing.

- If your primary focus is Dimensional Precision: Ensure the cooling phase after the 650°C soak is sufficiently slow to prevent late-stage warping.

Treat the annealing phase not as a passive cooling period, but as an active manufacturing step that dictates the final quality of the bond.

Summary Table:

| Feature | 650°C Annealing Impact |

|---|---|

| Primary Objective | Stress Relief & Interfacial Stabilization |

| Structural Benefit | Prevents delamination & cracking at the bond interface |

| Dimensional Effect | Ensures long-term stability and prevents post-machining warping |

| Microstructure | Relaxes the crystal lattice and equalizes thermal expansion mismatch |

| Critical Risk | Skipping leads to shearing forces and catastrophic failure |

Maximize Your Composite Quality with KINTEK Precision

Don't let residual stress compromise your high-value forgings. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab high-temp furnaces designed to master the complex thermal cycles required for composite materials.

Our advanced furnace technology ensures the precise temperature uniformity and controlled cooling rates necessary to prevent delamination and stabilize your 42CrMo/Cr5 components. Contact us today to optimize your heat treatment process and secure the structural integrity of your unique engineering projects.

Visual Guide

References

- Ming Li, S.W. Xin. Interface Microstructure and Properties of 42CrMo/Cr5 Vacuum Billet Forged Composite Roll. DOI: 10.3390/ma18010122

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the function of a laboratory vacuum drying oven when loading metal nanoparticles onto porous carbon particles?

- What is the purpose of performing a quenching treatment? Optimize Doped Alkali Halide Crystal Spectral Analysis

- What is the primary function of a laboratory blast drying oven? Essential Prep for La-EPS-C-450 Ceramic Adsorbents

- What role does a laboratory blast drying oven play in the preparation of Ti-doped Mn3O4? Optimize Your Precursor Quality

- What are the primary advantages of using powder metallurgy for Ti and TiZr alloys? Achieve Ultimate Structural Precision

- What is the importance of transferring freshly deposited CuO films directly into a 125°C oven? Ensure Film Adhesion

- What role does an oscillating heating stage play in WO3 thin film growth? Control Kinetics and Crystal Orientation

- Why is a high-purity argon flow required during the thermal reduction of nitrogen-doped graphene oxide?