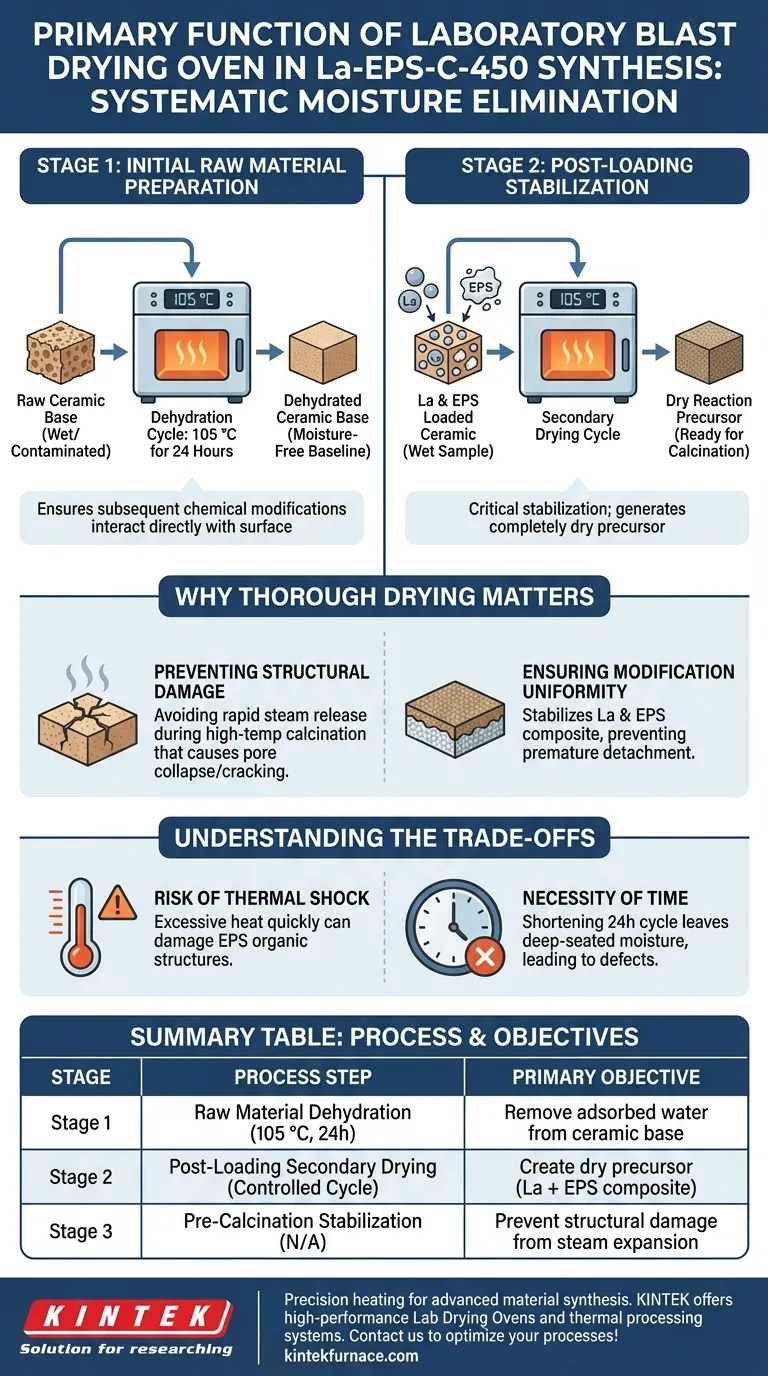

The primary function of a laboratory blast drying oven in the synthesis of La-EPS-C-450 is to systematically eliminate moisture at two distinct points in the preparation workflow. It is initially employed to dehydrate cleaned raw ceramic materials at 105 °C for 24 hours and is subsequently used for the secondary drying of samples after they have been loaded with lanthanum (La) and extracellular polymeric substances (EPS).

The drying process is not merely about water removal; it is a critical stabilization step that generates a completely dry reaction precursor. This ensures the material is physically stable and ready for the rigors of the subsequent high-temperature calcination process.

Stage 1: Initial Raw Material Preparation

Dehydrating the Ceramic Base

Before any modification occurs, the raw ceramic substrate must be completely free of contaminants and moisture.

The blast drying oven operates at 105 °C for a continuous 24-hour cycle to treat the cleaned raw materials.

Establishing a Baseline

This step removes physically adsorbed water from the ceramic structure.

By starting with a thoroughly dehydrated base, researchers ensure that subsequent chemical modifications interact directly with the ceramic surface rather than with residual moisture.

Stage 2: Post-Loading Stabilization

Secondary Drying of the Composite

Once the ceramic has been loaded with lanthanum (La) and EPS, the material becomes a "wet sample" again.

The blast drying oven is utilized a second time to perform secondary drying on these modified samples.

Preparing for Calcination

The goal of this stage is to create a "dry reaction precursor."

The material must be completely devoid of free moisture before it enters the high-temperature calcination phase.

Why Thorough Drying Matters

Preventing Structural Damage

While the primary reference focuses on the "what," understanding the "why" is essential for process control.

If moisture remains within the internal structure during high-temperature processing, rapid steam release can occur.

This sudden expansion can cause irregular pore collapse or structural cracking, compromising the mechanical integrity of the final adsorbent.

Ensuring Modification Uniformity

Proper drying ensures that the La and EPS components are settled onto the ceramic surface without interference from evaporating solvents during the heating ramp.

This stabilizes the composite structure, preventing the "binder" or active components from detaching or degrading prematurely.

Understanding the Trade-offs

The Risk of Thermal Shock

While blast drying is efficient, specific temperature control is vital.

Applying excessive heat too quickly to a wet composite can damage temperature-sensitive components, such as the organic structures within EPS.

The Necessity of Time

There is often a temptation to shorten the 24-hour drying cycle to speed up production.

However, shortening this window risks leaving deep-seated moisture in the ceramic pores, which will inevitably lead to defects during the final calcination.

Making the Right Choice for Your Goal

To ensure the highest quality La-EPS-C-450 adsorbent, apply the drying process based on your specific preparation phase:

- If your primary focus is substrate integrity: Strictly adhere to the 105 °C temperature for 24 hours for raw materials to guarantee the complete removal of physically adsorbed water.

- If your primary focus is coating stability: Ensure the secondary drying phase is exhaustive to produce a fully dry precursor, preventing steam-induced damage during calcination.

Successful adsorbent preparation relies on the blast drying oven effectively acting as the gatekeeper between wet chemistry and high-temperature thermal treatment.

Summary Table:

| Stage | Process Step | Temperature & Duration | Primary Objective |

|---|---|---|---|

| Stage 1 | Raw Material Dehydration | 105 °C for 24 Hours | Remove adsorbed water from ceramic base |

| Stage 2 | Post-Loading Secondary Drying | Controlled Cycle | Create dry precursor (La + EPS composite) |

| Stage 3 | Pre-Calcination Stabilization | N/A | Prevent structural damage from steam expansion |

Precision heating is the backbone of advanced material synthesis. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside lab drying ovens, all customizable for your unique research needs. Whether you are preparing ceramic adsorbents or complex composites, our equipment ensures the thermal stability and uniformity your project demands. Contact KINTEK today to optimize your lab's thermal processes!

Visual Guide

References

- Yaoyao Lu, Ren‐Cun Jin. Lanthanum and Sludge Extracellular Polymeric Substances Coprecipitation-Modified Ceramic for Treating Low Phosphorus-Bearing Wastewater. DOI: 10.3390/w17081237

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the role of a customized drying station with nitrogen purging? Optimize Polymer Blend Membrane Processing

- Why must raw kaolin undergo heat treatment for DLP 3D printing? Control Viscosity for Precision Printing

- What is the primary purpose of using a laboratory constant temperature drying oven for fuel sample preparation?

- What role does an RTA system play in processing SiN thin films? Unlock High-Performance Quantum & Optical Materials

- Why is the water quenching process necessary for high-entropy alloys? Master Phase Purity and Microstructural Integrity

- Why is an equivalent diffusion combustion heat source term integrated into the furnace temperature field simulation?

- How is the graphitization degree quantified using Raman spectroscopy? Master the $I_D/I_G$ Ratio for Carbon Materials

- How do laboratory thermostatic baths contribute to the phosphoric acid treatment of 3Y-TZP ceramics? Boost Bioactivity