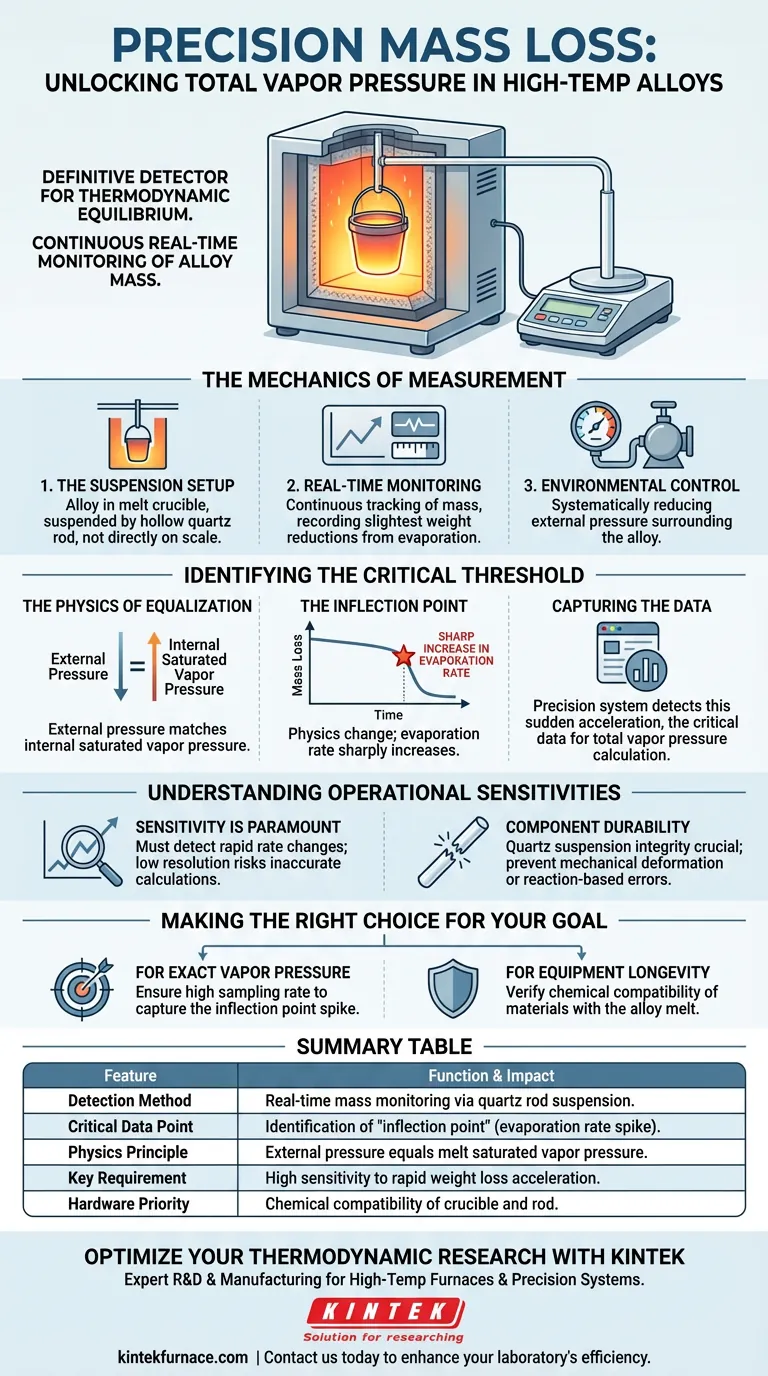

A precision mass loss measurement system serves as the definitive detector for identifying the thermodynamic equilibrium of an alloy in high-temperature environments. By suspending a melt crucible—typically via a hollow quartz rod—this system continuously monitors the sample's weight in real-time to detect specific changes in evaporation behavior as environmental conditions shift.

The system acts as a "tripwire" to identify the critical inflection point where evaporation rates spike. This sharp increase in mass loss signals that the external pressure has equalized with the melt's saturated vapor pressure, providing the exact data point needed to determine total vapor pressure.

The Mechanics of Measurement

The Suspension Setup

To achieve accurate readings inside a high-temperature furnace, the alloy is not weighed directly on a scale. Instead, it is placed in a melt crucible which is suspended by a hollow quartz rod.

Real-Time Monitoring

This suspension system connects to the precision measurement unit, allowing for continuous tracking of the alloy's mass. The system records the slightest weight reductions caused by evaporation over time.

Environmental Control

While the mass is being monitored, the furnace environment is manipulated. Specifically, the external pressure surrounding the alloy is systematically reduced.

Identifying the Critical Threshold

The Physics of Equalization

The goal of the measurement is to find the exact moment of pressure equalization. This occurs when the controlled external environment pressure drops to a level that matches the internal saturated vapor pressure of the alloy melt.

The Inflection Point

When these two pressures equalize, the physics of the alloy change dramatically. The evaporation rate does not just continue steadily; it increases sharply.

Capturing the Data

The precision mass loss system detects this sudden acceleration in weight loss. This specific moment—the "inflection point"—is the critical piece of data used to calculate the total vapor pressure.

Understanding Operational Sensitivities

Sensitivity is Paramount

The effectiveness of this method relies entirely on the system's ability to detect rapid rate changes. A system with low resolution may miss the exact onset of the inflection point, leading to inaccurate vapor pressure calculations.

Component Durability

The use of a quartz suspension rod is standard, but it introduces material constraints. The structural integrity of the suspension system must be maintained at high temperatures to ensure that mass changes are due to evaporation, not mechanical deformation.

Making the Right Choice for Your Goal

To ensure you are deriving accurate thermodynamic data from your furnace operations, consider the following regarding your measurement system:

- If your primary focus is determining exact vapor pressure: Ensure your system's sampling rate is high enough to capture the immediate spike in evaporation rate at the inflection point.

- If your primary focus is equipment longevity: Verify that the quartz suspension rod and crucible materials are chemically compatible with the specific alloy melt to prevent reaction-based mass errors.

Accurate vapor pressure determination depends less on the heat itself, and more on precisely identifying the moment evaporation accelerates.

Summary Table:

| Feature | Function & Impact |

|---|---|

| Detection Method | Real-time monitoring of mass via hollow quartz rod suspension |

| Critical Data Point | Identification of the 'inflection point' where evaporation rates spike |

| Physics Principle | Equalization of external pressure with melt saturated vapor pressure |

| Key Requirement | High sensitivity to capture rapid acceleration in weight loss |

| Hardware Priority | Chemical compatibility of crucible and rod with the alloy melt |

Optimize Your Thermodynamic Research with KINTEK

Precise vapor pressure determination requires equipment that remains stable under extreme conditions. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab high-temp furnaces designed to integrate seamlessly with precision measurement units.

Whether you are studying alloy evaporation or advanced material synthesis, our tailored solutions ensure the accuracy and durability your research demands. Contact us today to discuss your unique project needs and see how KINTEK can enhance your laboratory's efficiency.

Visual Guide

References

- В. Н. Володин, Azamat Tulegenov. Thermodynamics of Liquid Alloys and Vapor–Liquid Equilibrium in the Antimony–Tellurium System. DOI: 10.1007/s12540-023-01564-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the importance of a laboratory oven's programmed heating for epoxy-polyimide curing? Essential Thermal Control

- How does calcination temperature affect CuO grain growth? Optimize Nanoporous Film Morphology and Crystallinity

- What role does a vacuum oven play in determining the moisture content of mercury-depleted coal adsorbents? Key Insights

- What are the equipment requirements for high-temperature furnaces during magnetic biochar synthesis? Find the key specs.

- How does a constant temperature heating device influence battery performance? Enhance Lithium Dendrite Research Accuracy

- How do atomizers and furnaces function in Spray Pyrolysis? Master Nanoparticle Synthesis

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits

- What is the function of a laboratory hot air drying oven in TiO2 treatment? Ensure Uniform Nanoparticle Quality