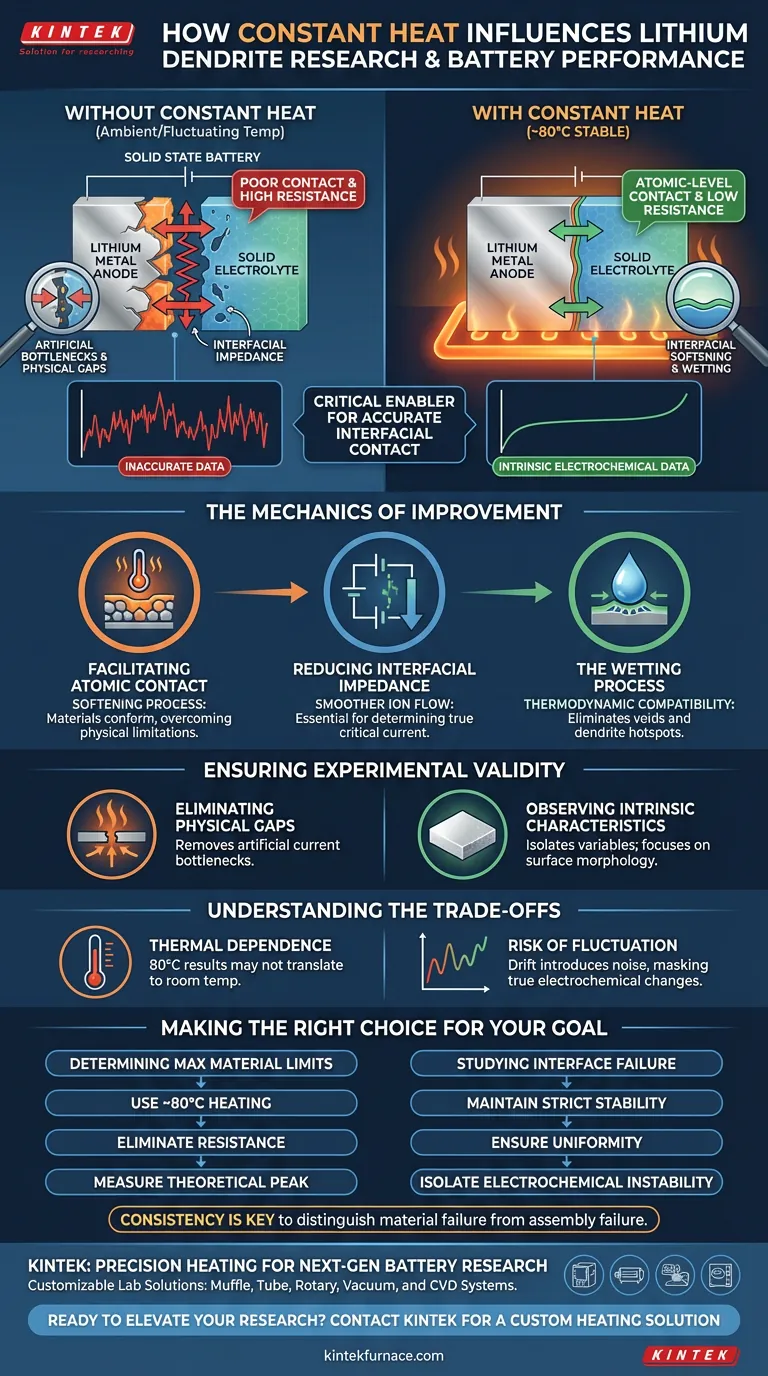

A constant temperature heating device acts as a critical enabler for accurate interfacial contact. By maintaining a stable thermal environment—often around 80°C—it facilitates atomic-level contact between the lithium metal anode and the solid electrolyte. This process significantly reduces interfacial impedance, which is a primary barrier to accurate measurement in solid-state battery experiments.

The application of consistent heat induces an interfacial softening and wetting process. This ensures that the data collected regarding critical current reflects the intrinsic electrochemical capabilities of the material, rather than physical defects or poor contact points.

The Mechanics of Interfacial Improvement

Facilitating Atomic-Level Contact

The primary function of the heating device is to overcome the physical limitations of solid-solid interfaces.

At elevated temperatures, the materials undergo a softening process. This allows the lithium metal anode to conform more perfectly to the surface of the solid electrolyte, establishing contact at the atomic level.

Reducing Interfacial Impedance

Poor contact naturally creates high resistance, known as interfacial impedance.

By using a heating device to ensure better physical mating of the components, you actively lower this impedance. This allows for a smoother flow of ions, which is essential for determining the true critical current density the cell can handle.

The Wetting Process

Heat promotes a phenomenon known as "wetting" between the anode and the electrolyte.

This is not "wet" in the liquid sense, but rather a thermodynamic compatibility where the materials bond more effectively. This wetting eliminates microscopic voids that would otherwise act as hotspots for dendrite nucleation.

Ensuring Experimental Validity

Eliminating Physical Gaps

Without controlled heating, physical gaps often persist between battery components.

These gaps create artificial bottlenecks for current. If you attempt to measure critical current with these gaps present, your results will be skewed by the physical geometry of the gap rather than the chemistry of the battery.

Observing Intrinsic Characteristics

The ultimate goal of using a constant temperature is data fidelity.

By standardizing the thermal environment and removing physical contact issues, you isolate the variables. This ensures that any dendrite growth or failure observed during cycling is caused by the surface morphology and electrochemical nature of the materials, not by inconsistent assembly.

Understanding the Trade-offs

Thermal Dependence vs. Real-World Application

While heating is necessary for the experiment, it introduces a specific conditionality to your data.

Results obtained at 80°C represent the material's performance at that temperature. These results may not directly translate to room-temperature performance, where the interface is more rigid and impedance is naturally higher.

The Risk of Fluctuation

The "constant" aspect of the device is just as important as the heat itself.

If the heating device allows temperatures to drift, the interfacial resistance will fluctuate in real-time. This introduces noise into the data, making it impossible to distinguish between electrochemical changes and simple thermal variance.

Making the Right Choice for Your Goal

To ensure your critical current evaluations are valid, apply the heating strategy based on your specific research focus:

- If your primary focus is determining maximum material limits: Use the heating device to reach ~80°C to eliminate all physical contact resistance and measure the theoretical peak performance.

- If your primary focus is studying interface failure mechanisms: Maintain strict temperature stability to ensure that any observed dendrite growth is a result of electrochemical instability, not physical delamination.

Consistency in thermal application is the only way to distinguish between a material failure and an assembly failure.

Summary Table:

| Factor | Influence of Constant Heating | Impact on Data Accuracy |

|---|---|---|

| Interfacial Contact | Facilitates atomic-level contact through material softening | High: Eliminates physical gaps and voids |

| Impedance | Significantly reduces interfacial resistance | High: Isolates intrinsic electrochemical behavior |

| Wetting Process | Promotes thermodynamic compatibility between anode and electrolyte | Medium: Prevents hotspots for dendrite nucleation |

| Data Fidelity | Standardizes thermal environment to remove noise | High: Distinguishes material failure from assembly failure |

Precision Heating for Next-Gen Battery Research

Don't let interfacial impedance or thermal fluctuations compromise your lithium dendrite research. KINTEK provides high-precision thermal solutions specifically designed for the rigorous demands of solid-state battery testing.

Backed by expert R&D and manufacturing, KINTEK offers a wide range of lab solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique experimental needs. Whether you are aiming to reach theoretical peak performance at 80°C or study complex interface failure mechanisms, our equipment ensures the stability required for reliable data.

Ready to elevate your battery material characterization? Contact KINTEK today for a custom heating solution.

Visual Guide

References

- Shengming Zhang, Peter G. Bruce. Influence of contouring the lithium metal/solid electrolyte interface on the critical current for dendrites. DOI: 10.1039/d3ee03322h

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- What is the function of a laboratory vacuum drying oven in BAFPAE processing? Maintain Precursor Purity and Stability

- How do continuous furnaces differ from batch furnaces? Choose the Right Furnace for Your Production Needs

- What is the role of MgO powder in Nickel-Aluminum VCS? Achieve Precise Thermal Control & Powder Quality

- What are the advantages of using a vacuum oven for drying porous carbon? Protect Microstructures & Prevent Oxidation

- Why is a high-precision programmed heating furnace essential for the annealing reduction of intermetallic compounds?

- How does the sintering process enhance conventional ceramics with Alumina? Boost Strength and Insulation

- Why is vacuum sealing technology essential for K2In2As3 synthesis? Master High-Purity Solid-State Reactions

- What is the significance of using different sizes of steel working ampoules? Precision vs. Efficiency in Lab Research