Beyond simple isolation, a vacuum chamber fundamentally enhances processes by removing the atmospheric particles that cause unwanted chemical reactions and physical interference. This leads directly to reduced contamination, superior material properties, and increased equipment longevity by preventing the damaging effects of oxidation.

A vacuum is not a passive environment; it is an active tool. By removing air and other contaminants, you are not just protecting a process from the outside world—you are fundamentally improving its outcome by eliminating the primary source of chemical and physical defects.

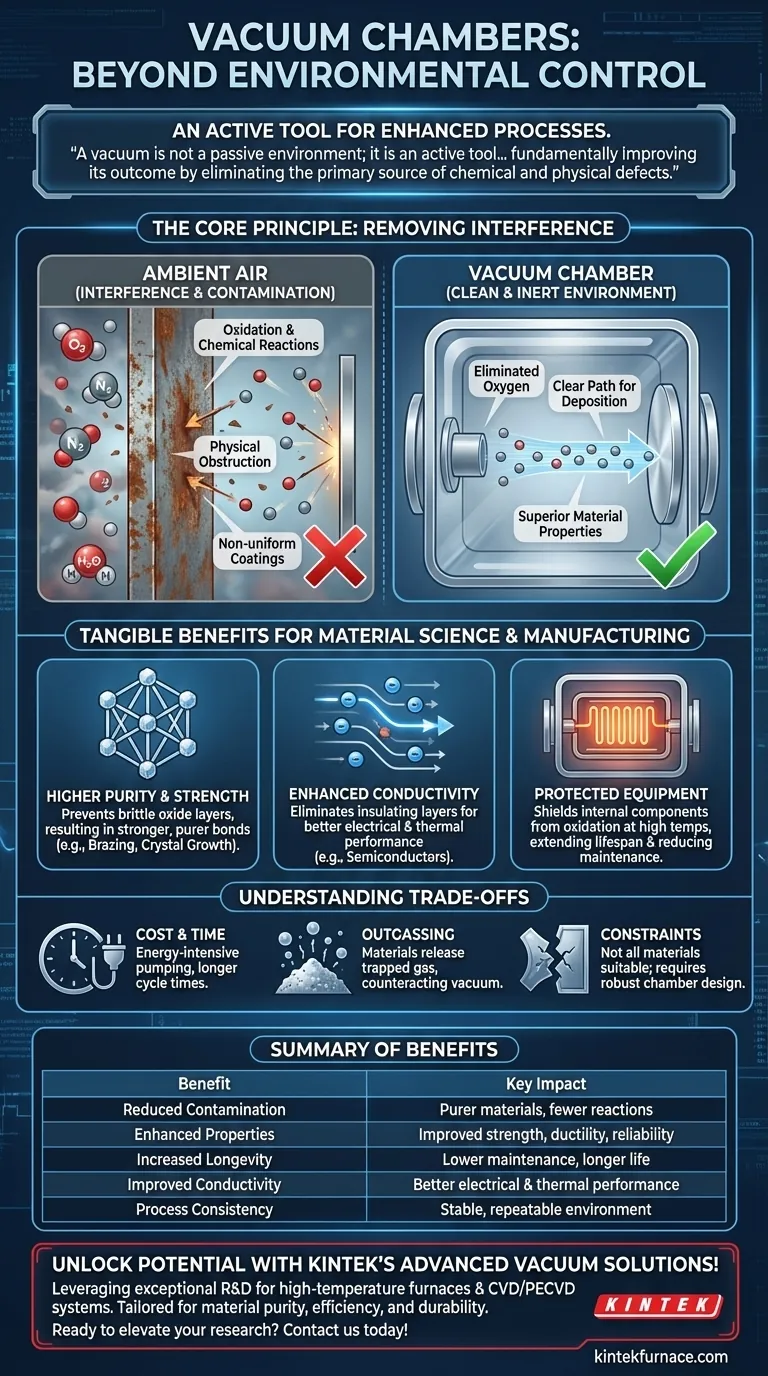

The Core Principle: Removing Interference

The primary function of a vacuum chamber is to pump out the molecules of air and other gases. This seemingly simple action has profound effects because it removes the agents of interference from your process.

Eliminating Unwanted Chemical Reactions

The air around us is about 21% oxygen, a highly reactive element. For many materials, exposure to oxygen causes oxidation—a chemical reaction that degrades material properties.

By removing oxygen, a vacuum chamber creates a chemically inert environment. This prevents metals from rusting, sensitive electronics from degrading, and chemical compounds from reacting in unintended ways.

Preventing Physical Obstruction

Even non-reactive gases like nitrogen can cause problems. In processes like thin-film deposition or coating, individual gas molecules act as physical obstacles.

Atoms of the material being deposited can collide with these gas molecules, deflecting them from their intended path. This leads to non-uniform coatings and structural defects, compromising the quality of the final product. A vacuum clears this path, ensuring a direct line of sight between the source and the target.

Tangible Benefits for Material Science and Manufacturing

By controlling the chemical and physical environment at a molecular level, vacuum chambers deliver critical advantages that are impossible to achieve in ambient conditions.

Achieving Higher Material Purity and Strength

Contaminants, especially oxides, create weak points within a material's structure. In metallurgy, for example, vacuum brazing or welding prevents the formation of brittle oxide layers in the joint.

This results in a stronger, more ductile, and more reliable bond. In crystal growth, a vacuum ensures that impurities from the air are not incorporated into the crystal lattice, leading to a much purer and more perfect final structure.

Enhancing Electrical and Thermal Conductivity

Oxide layers and other impurities act as insulators. They impede the flow of electrons (electrical current) and phonons (heat), degrading a material's conductive properties.

Processing materials in a vacuum prevents the formation of these insulating layers. This is critical for manufacturing high-performance semiconductors, superconductors, and thermal management components where maximum conductivity is essential.

Protecting Sensitive Equipment

The benefits of preventing oxidation extend to the equipment itself. Many processes, such as plasma etching or heat treating, run at high temperatures that accelerate oxidation.

Operating in a vacuum protects not only the material being processed but also the internal components of the chamber, such as heating elements and fixtures. This significantly increases their operational lifespan and reduces maintenance costs.

Understanding the Trade-offs

While powerful, vacuum technology is not a universal solution and comes with its own set of challenges that require careful management.

The Cost of Purity: Pumping and Time

Achieving a high-quality vacuum is an energy- and time-intensive process. It requires sophisticated and expensive pumps, and the "pump-down" time to reach the target pressure can significantly add to the overall cycle time of a manufacturing process.

The Challenge of Outgassing

A perfect vacuum is a theoretical ideal. In reality, materials placed inside the chamber—and even the chamber walls themselves—will slowly release trapped gases and moisture. This phenomenon, known as outgassing, actively works against the vacuum pump and can be a major source of contamination if not properly managed.

Material and Design Constraints

Not all materials are suitable for use in a vacuum. Plastics can break down, and some materials have high vapor pressures, meaning they will essentially evaporate and contaminate the chamber. The chamber itself must be robustly engineered to withstand immense external atmospheric pressure without leaking or collapsing.

Applying Vacuum Principles to Your Goal

The decision to use a vacuum system depends entirely on what you need to achieve. The level of vacuum required is dictated by the specific contaminants or interference you are trying to remove.

- If your primary focus is material purity (e.g., semiconductors, medical implants): Your goal is to eliminate reactive gases like oxygen and water vapor that cause chemical contamination and degrade performance.

- If your primary focus is physical structure (e.g., optical coatings, aerospace alloys): You need to remove all particles that could physically obstruct processes like thin-film deposition or create voids in brazed joints.

- If your primary focus is process consistency (e.g., mass manufacturing): A vacuum provides a perfectly stable and repeatable environment, free from the unpredictable fluctuations in humidity, pressure, and airborne particulates found in ambient air.

Ultimately, a vacuum is a powerful tool for refining and perfecting materials and processes at a molecular level.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Reduced Contamination | Prevents oxidation and unwanted chemical reactions, leading to purer materials |

| Enhanced Material Properties | Improves strength, ductility, and reliability in processes like brazing and crystal growth |

| Increased Equipment Longevity | Protects internal components from oxidation, reducing maintenance costs |

| Improved Conductivity | Eliminates insulating layers for better electrical and thermal performance |

| Process Consistency | Provides a stable, repeatable environment free from atmospheric fluctuations |

Unlock the full potential of your laboratory with KINTEK's advanced vacuum solutions!

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, enhancing material purity, process efficiency, and equipment durability.

Ready to elevate your research and manufacturing outcomes? Contact us today to discuss how our tailored solutions can benefit your specific applications!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure