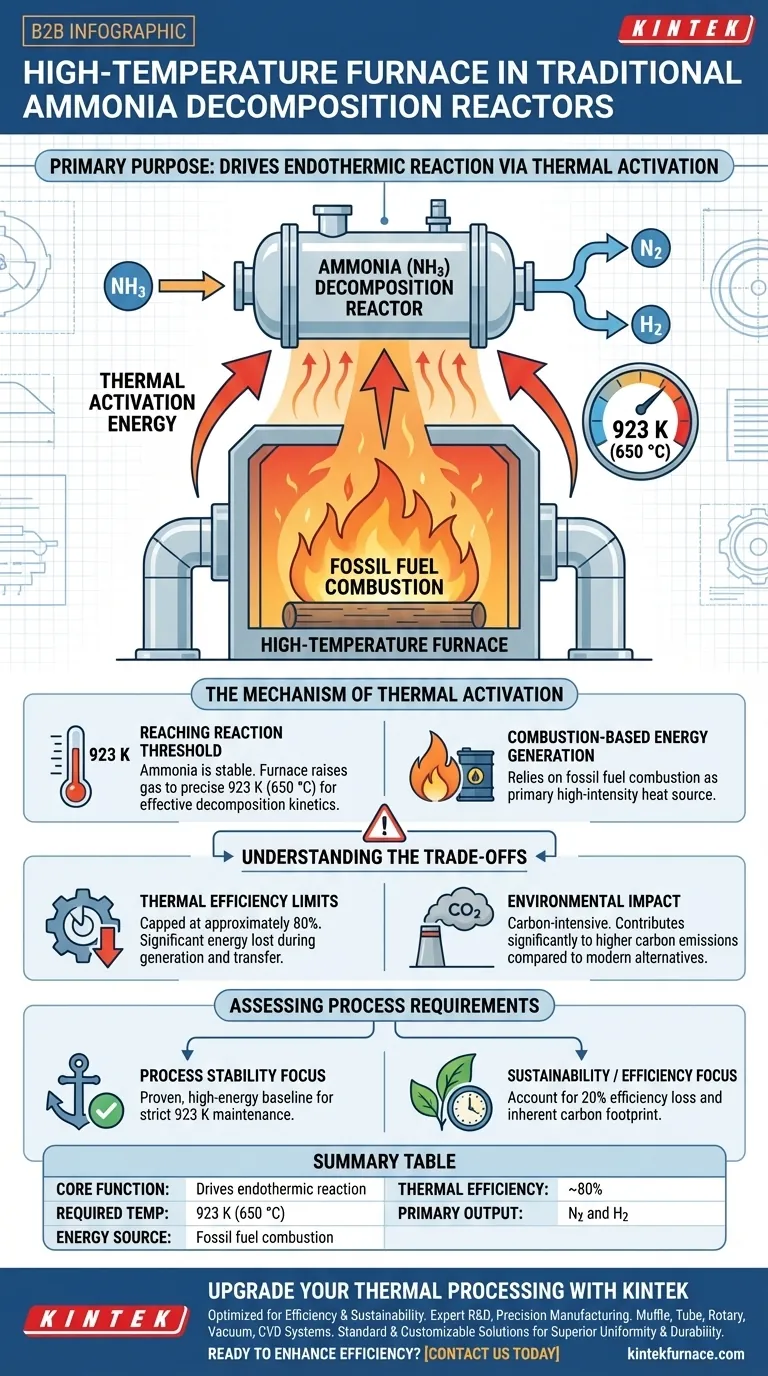

In traditional ammonia decomposition reactors, the high-temperature furnace functions as the central heating unit designed to drive the endothermic reaction. Its specific role is to generate heat via fossil fuel combustion to elevate the ammonia gas to a mandatory reaction temperature of 923 K (650 °C).

The furnace provides the necessary thermal activation energy to break down ammonia, but this reliability comes at the cost of capped thermal efficiency and increased carbon emissions.

The Mechanism of Thermal Activation

Reaching the Reaction Threshold

Ammonia is a stable compound that requires significant energy input to decompose into nitrogen and hydrogen.

The furnace is engineered to raise the temperature of the gas to a precise level of 923 K (650 °C). Without achieving this thermal threshold, the reaction kinetics are insufficient for effective decomposition.

Combustion-Based Energy Generation

Unlike electrically heated or catalytic systems, traditional furnaces rely on the combustion of fossil fuels.

This combustion acts as the primary driver for thermal energy, providing a continuous and high-intensity heat source to the reactor vessel.

Understanding the Trade-offs

Thermal Efficiency Limits

While these furnaces are effective at generating high heat, they struggle with energy retention and transfer.

The thermal efficiency of a traditional furnace in this context is generally capped at approximately 80%. This indicates a significant portion of the energy generated by burning fuel is lost rather than utilized for the reaction.

Environmental Impact

The reliance on fossil fuel combustion creates a direct link between ammonia decomposition and environmental pollutants.

Because the heat generation process is carbon-intensive, these traditional systems contribute significantly to higher carbon emissions compared to modern, electrified, or catalytic alternatives.

Assessing Process Requirements

When evaluating the role of a traditional furnace in your infrastructure, consider the balance between operational stability and environmental cost.

- If your primary focus is process stability: The traditional furnace provides a proven, high-energy baseline capable of maintaining the strict 923 K temperature requirement.

- If your primary focus is sustainability or efficiency: You must account for the 20% thermal efficiency loss and the carbon footprint inherent in fossil fuel combustion systems.

Understanding that the furnace is a tool for thermal activation—not just heat generation—allows you to better evaluate its efficiency relative to its environmental cost.

Summary Table:

| Feature | Specification/Detail |

|---|---|

| Core Function | Drives endothermic reaction via thermal activation |

| Required Temperature | 923 K (650 °C) |

| Energy Source | Fossil fuel combustion |

| Thermal Efficiency | Approximately 80% |

| Primary Output | Nitrogen (N2) and Hydrogen (H2) |

Upgrade Your Thermal Processing with KINTEK

Is your production limited by thermal efficiency or environmental constraints? KINTEK provides high-performance solutions designed to optimize your laboratory and industrial workflows.

Backed by expert R&D and precision manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard high-temperature furnaces or fully customizable systems tailored to your unique decomposition requirements, KINTEK ensures superior temperature uniformity and durability.

Ready to enhance your process efficiency? Contact us today to consult with our specialists!

Visual Guide

References

- Jian Tiong Lim, Hwei Ru Ong. Techno-Economic Analysis of Onsite Sustainable Hydrogen Production via Ammonia Decomposition with Heat Recovery System. DOI: 10.3390/su17125399

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does a precision temperature-controlled heating furnace enhance medium-entropy alloys? Achieve Optimal Hardness

- How does a solvothermal reactor contribute to silver nanowires synthesis? Precision Growth for High-Aspect-Ratio AgNWs

- What are the process advantages of using PVT compared to solution methods for organic crystals? Enhance Purity & Uniformity

- Why is titanium used as a gettering agent in TiCo1-xCrxSb preparation? Achieve Purity in Your Alloy Synthesis

- What role does a high-temperature blast drying oven play in nanocomposite formation? Ensure Structural Stability

- What are the advantages of Spark Plasma Sintering (SPS) for diffusion bonding? Precision in Atomic Diffusion

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- Why is Water Quenching Critical for Metastable Phases in Titanium? Unlock High-Performance Alloy Strength