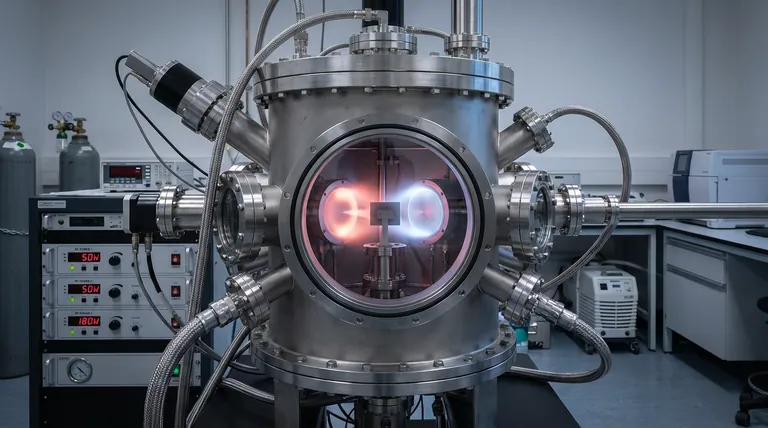

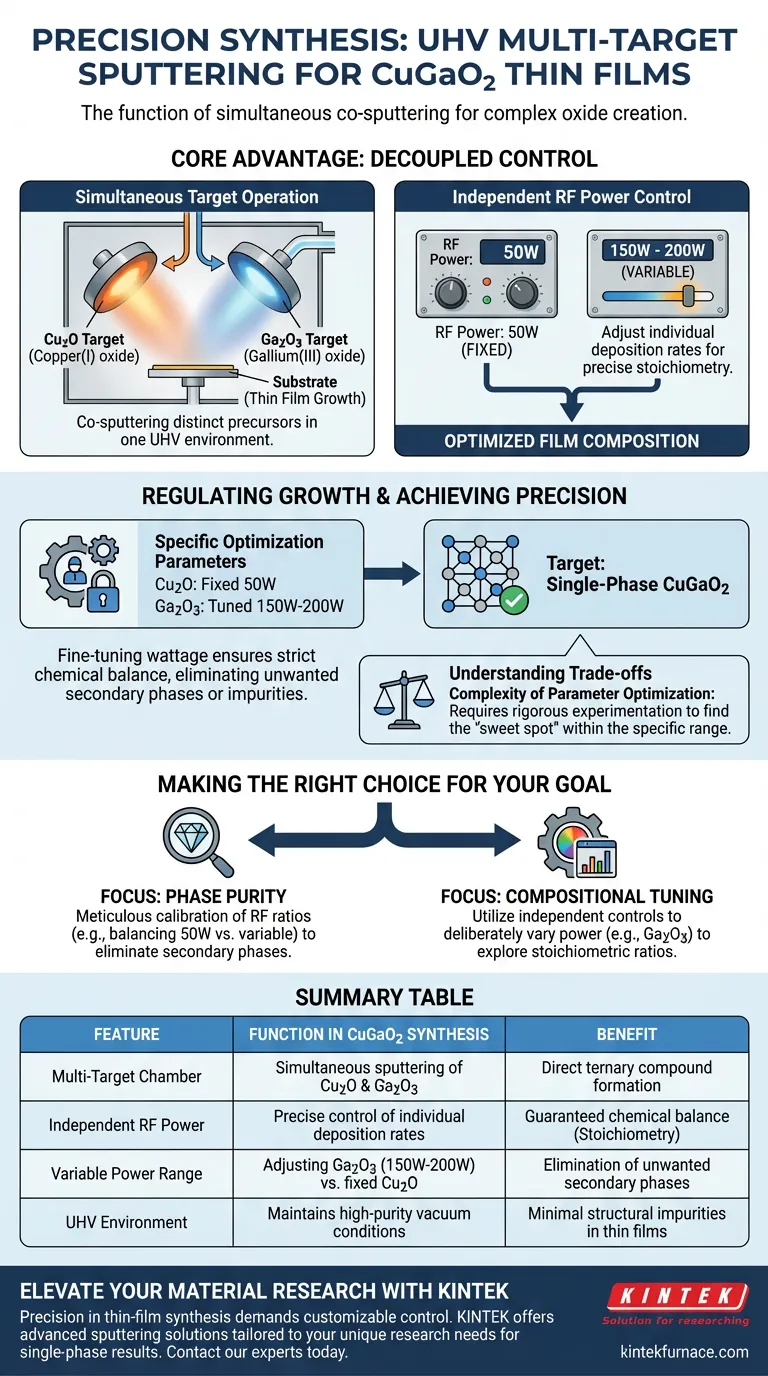

An ultra-high vacuum sputtering system with multi-target capabilities functions as a precision synthesis tool that allows for the simultaneous co-sputtering of distinct source materials, such as Cu2O and Ga2O3, to create complex CuGaO2 thin films. By operating multiple targets within a single chamber, researchers can independently regulate the deposition rate of each element to achieve the exact chemical balance required for the material.

The core advantage of this system is the ability to decouple the control of individual precursors, enabling independent radio frequency (RF) power adjustments to optimize film composition and ensure the formation of single-phase CuGaO2.

Achieving Compositional Precision

Simultaneous Target Operation

The defining feature of this system is its ability to house and operate multiple target positions within the same vacuum environment.

Instead of relying on a single, pre-mixed target, the system utilizes separate targets for the constituent materials, specifically Cu2O (Copper(I) oxide) and Ga2O3 (Gallium(III) oxide).

Operating these targets simultaneously is essential for synthesizing the ternary compound CuGaO2 directly on the substrate.

Independent RF Power Control

To achieve the correct stoichiometry, the system allows for the independent adjustment of radio frequency (RF) power for each target.

Different materials have different sputtering yields; applying the same power to both targets would likely result in an incorrect chemical ratio.

Independent control allows the operator to "throttle" the deposition rate of one material up or down without affecting the other.

Regulating Growth via Power Adjustments

Specific Optimization Parameters

Precise regulation of sputtering rates is achieved by locking one variable while tuning the other.

For example, the primary reference notes that a researcher can maintain the Cu2O target at a fixed 50W.

Simultaneously, the power applied to the Ga2O3 target can be adjusted between 150W and 200W.

Targeting Single-Phase Synthesis

The ultimate goal of this differential power application is to synthesize single-phase CuGaO2.

If the ratio of Copper to Gallium is incorrect due to improper power settings, the resulting film may contain unwanted secondary phases or structural impurities.

By fine-tuning the wattage within the specified range, the system ensures the film composition is strictly controlled.

Understanding the Trade-offs

Complexity of Parameter Optimization

While multi-target co-sputtering offers superior control, it introduces significant complexity to the process window.

Unlike single-target sputtering, where the stoichiometry is fixed by the source material, this method requires rigorous experimentation to find the "sweet spot."

As indicated by the reference, there is a specific range (150W to 200W for Ga2O3) required for success; deviating outside this optimized window will fail to produce the desired single-phase material.

Making the Right Choice for Your Goal

When utilizing an ultra-high vacuum sputtering system for CuGaO2 synthesis, your approach should depend on your specific material objectives:

- If your primary focus is Phase Purity: meticulous calibration of the RF power ratios (e.g., balancing 50W Cu2O against variable Ga2O3) is required to eliminate secondary phases.

- If your primary focus is Compositional Tuning: utilize the independent target controls to deliberately vary the Ga2O3 power to explore different stoichiometric ratios for experimental analysis.

This system transforms standard physical vapor deposition into a tunable chemical synthesis process, giving you the control necessary to engineer high-quality complex oxides.

Summary Table:

| Feature | Function in CuGaO2 Synthesis | Benefit |

|---|---|---|

| Multi-Target Chamber | Simultaneous sputtering of Cu2O and Ga2O3 | Direct ternary compound formation |

| Independent RF Power | Precise control of individual deposition rates | Guaranteed chemical balance (Stoichiometry) |

| Variable Power Range | Adjusting Ga2O3 (150W-200W) vs. fixed Cu2O | Elimination of unwanted secondary phases |

| UHV Environment | Maintains high-purity vacuum conditions | Minimal structural impurities in thin films |

Elevate Your Material Research with KINTEK

Precision in thin-film synthesis requires more than just high vacuum—it demands customizable control. Backed by expert R&D and manufacturing, KINTEK offers advanced Muffle, Tube, Rotary, Vacuum, and CVD systems, including high-performance sputtering solutions tailored to your unique research needs. Whether you are synthesizing complex oxides like CuGaO2 or developing next-generation semiconductors, our lab high-temp furnaces and deposition systems provide the reliability you need for single-phase results.

Ready to optimize your deposition process? Contact us today to consult with our experts on a solution customized for your laboratory.

Visual Guide

References

- Akash Hari Bharath, Kalpathy B. Sundaram. Deposition and Optical Characterization of Sputter Deposited p-Type Delafossite CuGaO2 Thin Films Using Cu2O and Ga2O3 Targets. DOI: 10.3390/ma17071609

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is staged temperature control required in industrial air drying ovens for carbon nanofibers? Key Safety Insights

- Why is charcoal used as a susceptor in MHH for metal powders? Boost Microwave Efficiency with Hybrid Heating

- How does a precision drying oven influence ZnO gel drying? Achieve Perfect Microporous Structures

- What is the function of a forced air drying oven for biochar? Optimize Moringa Oleifera Shell Pre-treatment

- Why is a laboratory vacuum drying oven required for perovskite nanopowders? Safeguard Nanostructure and Purity

- How do laboratory tablet presses ensure performance in iodine battery prototypes? Optimize Interfacial Contact Today

- What is the primary purpose of using a laboratory constant temperature drying oven for fuel sample preparation?

- Why is an aging station required for Ni-doped LaFeO3 gas sensors? Ensure Stability and Precision