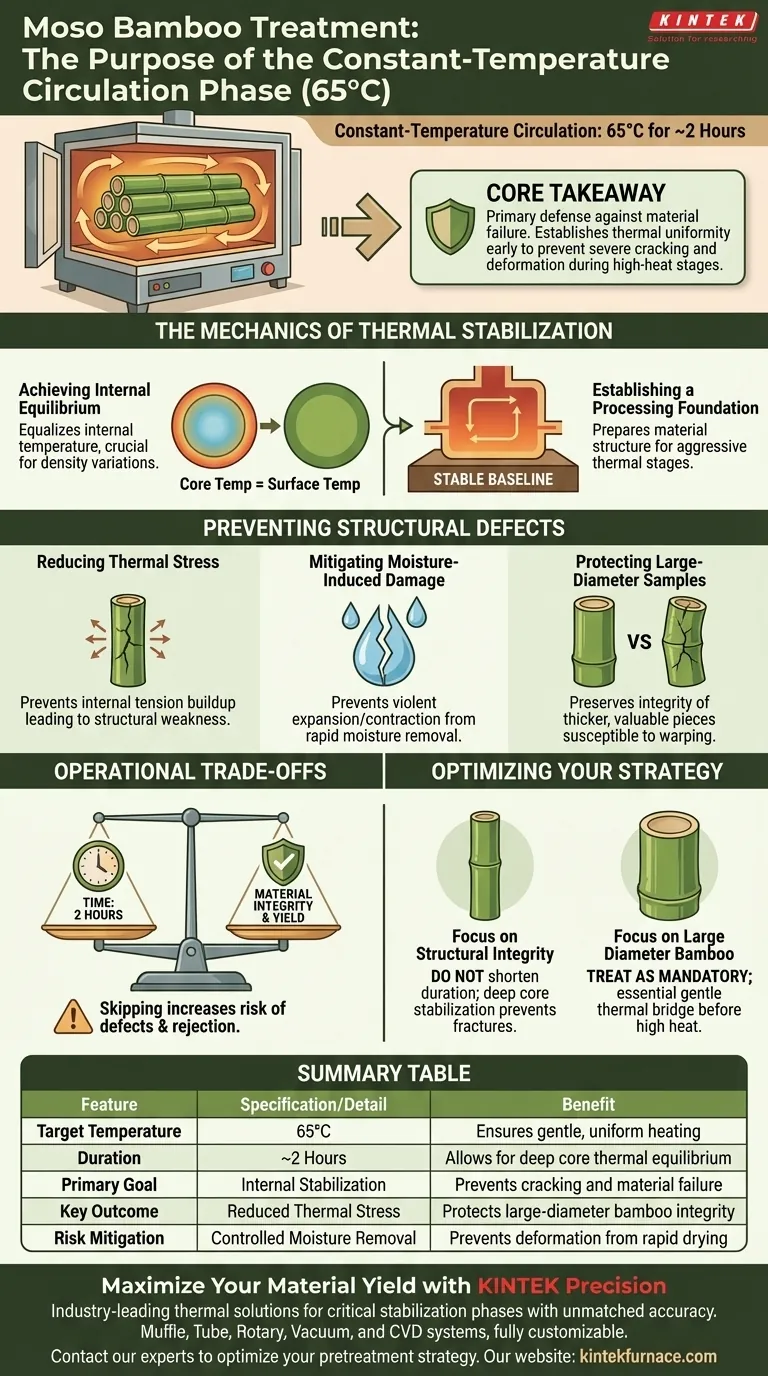

The constant-temperature circulation phase acts as a critical stabilization period where industrial furnaces maintain Moso Bamboo at 65°C for approximately two hours. This specific thermal plateau is designed to equalize the internal temperature of the bamboo samples before they are subjected to higher processing temperatures.

Core Takeaway This phase is the primary defense against material failure. By establishing thermal uniformity early, the process prevents the severe cracking and deformation that typically occur when large-diameter bamboo undergoes rapid moisture removal during later, high-heat stages.

The Mechanics of Thermal Stabilization

Achieving Internal Equilibrium

Bamboo is a material with significant density and thickness variations. This pretreatment phase ensures that the temperature at the core of the bamboo matches the surface temperature.

Establishing a Processing Foundation

Maintaining the furnace at 65°C for two hours creates a stable baseline. This uniformity prepares the material's physical structure for the more aggressive thermal stages that follow.

Preventing Structural Defects

Reducing Thermal Stress

When bamboo is heated unevenly, internal tension builds up rapidly. This "thermal stress" is a leading cause of structural weakness in the final product.

Mitigating Moisture-Induced Damage

Rapid moisture removal acts as a shock to the bamboo's cellular structure. By preheating the material gently, the system prevents the violent expansion or contraction that leads to splitting.

Protecting Large-Diameter Samples

Thicker bamboo poles are disproportionately susceptible to warping and cracking. This phase is specifically cited as a method to preserve the integrity of these larger, more valuable pieces.

Understanding the Operational Trade-offs

Time vs. Material Integrity

The primary trade-off in this phase is the allocation of processing time (two hours) against the risk of yield loss. While skipping this low-temperature hold might accelerate the production cycle, it drastically increases the probability of rejecting the final product due to defects.

The Limits of Stabilization

While effective, this phase is a preventative measure, not a cure. It establishes a foundation for improved physical properties, but it relies on the subsequent high-temperature stages being executed correctly to lock in those benefits.

Optimizing Your Treatment Strategy

To maximize the quality of Moso Bamboo products, consider how this phase aligns with your specific production goals:

- If your primary focus is Structural Integrity: Do not shorten the two-hour duration, as deep core stabilization is the only way to prevent internal fractures in the finished good.

- If your primary focus is Processing Large Diameter Bamboo: Treat the 65°C circulation phase as mandatory, as these samples cannot withstand high-heat drying without this gentle thermal bridge.

Effective pretreatment is not just about heating; it is about creating the thermal stability required for the bamboo to survive the drying process intact.

Summary Table:

| Feature | Specification/Detail | Benefit |

|---|---|---|

| Target Temperature | 65°C | Ensures gentle, uniform heating |

| Duration | Approximately 2 Hours | Allows for deep core thermal equilibrium |

| Primary Goal | Internal Stabilization | Prevents cracking and material failure |

| Key Outcome | Reduced Thermal Stress | Protects large-diameter bamboo integrity |

| Risk Mitigation | Controlled Moisture Removal | Prevents deformation from rapid drying |

Maximize Your Material Yield with KINTEK Precision

Don't let structural defects compromise your high-value Moso Bamboo production. KINTEK provides industry-leading thermal solutions designed to manage critical stabilization phases with unmatched accuracy.

Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the unique thermal profiles of organic materials like bamboo. Whether you need precise low-temperature circulation or high-heat processing, KINTEK lab high-temp furnaces ensure your products survive the drying process intact and defect-free.

Ready to optimize your pretreatment strategy? Contact our experts today to discover how our custom furnace solutions can enhance your laboratory or industrial efficiency.

Visual Guide

References

- Yesun Kim, Se‐Yeong Park. Improvement of Moso Bamboo (Phyllostachys pubescens) Properties Using a Heat Treatment Process for Landscaping Materials and Evaluation of Its Durability against Biotic/Abiotic Factors. DOI: 10.3390/f15010101

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does industrial heating equipment play in the manufacturing process of 55Si2 spring steel during winding?

- How does the elimination of double oxide films improve T7 over-aging? Unlock Superior Ductility in Aluminum Alloys

- How does calcination temperature affect CuO grain growth? Optimize Nanoporous Film Morphology and Crystallinity

- Why is a high-temperature sintering furnace critical for BCZT ceramics? Achieving High Densification and Performance

- How does diamond benefit 5G technology? Unlock Peak Performance with Superior Thermal Management

- What are the advantages of heterogeneous catalysts in HTL? Boost Biofuel Quality and Process Efficiency

- What is the function of a planetary high-energy ball mill in Al2O3/TiC ceramics? Achieve Sub-Micron Precision Today

- Why is a pre-melting process required in phase equilibrium studies? Reset Your Sample for Precise Results