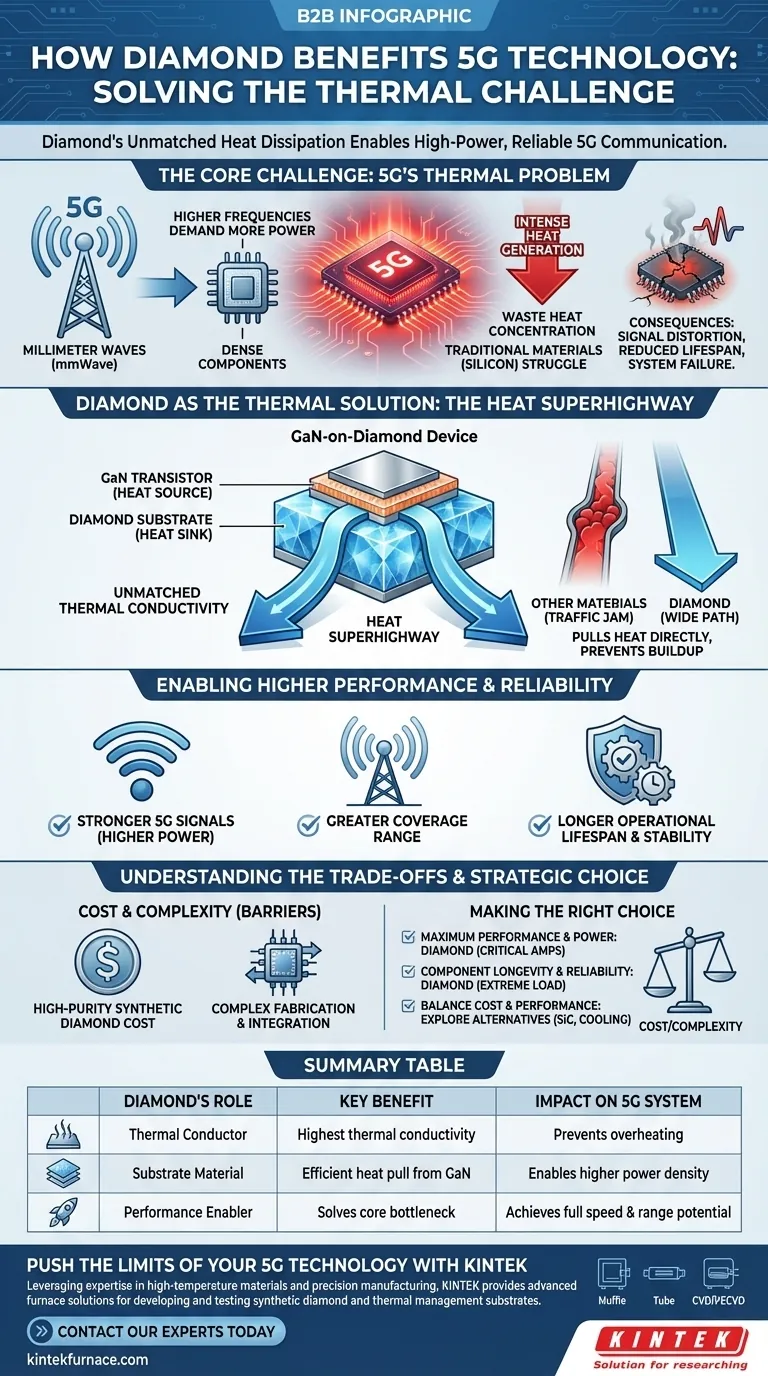

In short, diamond’s primary benefit to 5G technology is its unmatched ability to dissipate heat. As a substrate material for high-power electronic components, its exceptional thermal conductivity allows 5G systems to operate at the high power levels required for fast, reliable communication without overheating and failing.

5G technology pushes electronic components to their thermal limits, creating a critical performance bottleneck. Diamond isn't just an improvement; it's an enabling material that solves this core heat problem, allowing 5G to reach its full potential for power and speed.

The Core Challenge: 5G's Thermal Problem

To understand diamond's role, we must first understand why 5G generates so much heat. The leap in performance from 4G to 5G creates a fundamental engineering challenge centered on thermal management.

Higher Frequencies Demand More Power

5G leverages much higher frequency bands, including millimeter waves (mmWave), to achieve its massive bandwidth and speed.

Transmitting signals at these higher frequencies requires significantly more power concentrated into smaller, denser electronic components.

The Enemy is Heat

This intense concentration of power in a small area generates an immense amount of waste heat.

Materials traditionally used in electronics, like silicon or even advanced compounds, struggle to channel this heat away quickly enough.

Why Excess Heat is Catastrophic

When heat is not effectively removed, the consequences are severe.

It degrades the performance of radio frequency (RF) components, leading to signal distortion and reduced data speeds. Over time, it dramatically shortens the lifespan of the electronics and can cause complete system failure.

Diamond as the Thermal Solution

Diamond's unique physical properties make it the ideal solution for this specific thermal bottleneck. It acts less like a component and more like a fundamental enabler for the high-power parts of the system.

Unmatched Thermal Conductivity

Diamond has the highest thermal conductivity of any known bulk material, far surpassing copper and silicon.

Think of it as a heat superhighway. While other materials create a traffic jam for heat, diamond provides a wide, open path for thermal energy to escape from the active component.

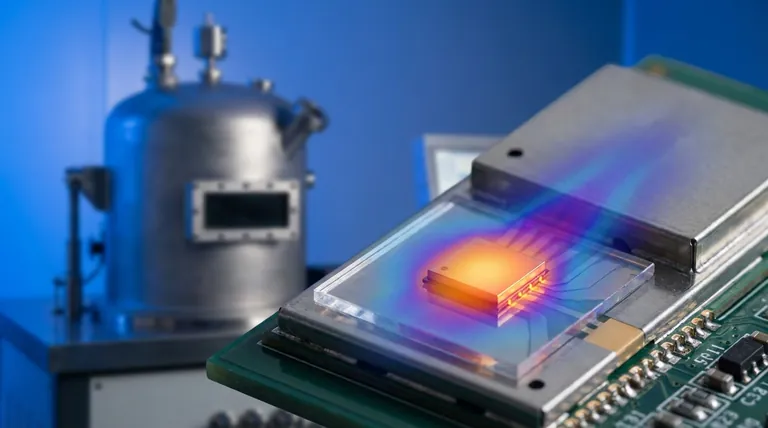

The Role of the Diamond Substrate

In 5G applications, high-power transistors, often made of Gallium Nitride (GaN), are grown or bonded directly onto a thin wafer of engineered diamond.

This diamond substrate acts as a highly efficient heat sink. It pulls heat directly from the source—the transistor—and spreads it out, preventing a dangerous thermal buildup.

Enabling Higher Performance and Reliability

By effectively solving the heat problem, diamond substrates allow engineers to push their components harder.

This means GaN-on-diamond devices can operate at higher power levels, resulting in stronger 5G signals, greater coverage range from base stations, and more stable, reliable network operation.

Understanding the Trade-offs

While diamond is a near-perfect thermal solution, its adoption is governed by practical and economic realities. It is not a universal replacement for all substrate materials.

The Significant Cost Factor

High-purity, electronics-grade synthetic diamond is expensive to produce. This cost is a major consideration, especially when compared to traditional substrate materials like silicon carbide (SiC).

This means its use is typically reserved for the most performance-critical and thermally stressed applications where no other material will suffice.

Manufacturing and Integration Complexity

Integrating diamond into existing semiconductor fabrication processes is a complex engineering challenge.

Perfectly bonding a layer of GaN to a diamond substrate without introducing defects that would impede thermal transfer requires specialized techniques and adds to the overall manufacturing cost and complexity.

Making the Right Choice for Your Goal

The decision to leverage diamond is a strategic one, based on balancing performance requirements against cost and complexity.

- If your primary focus is maximum 5G network performance and power: Using diamond substrates for critical power amplifiers in base stations is the most effective path to overcome thermal limits.

- If your primary focus is component longevity and reliability under extreme load: Diamond's superior heat dissipation directly translates to a longer operational lifespan and increased stability for high-power RF systems.

- If your primary focus is a balance of cost and performance: You may explore advanced cooling technologies or other substrate materials like SiC, accepting that you will not reach the absolute peak power density that diamond enables.

Ultimately, diamond serves as a crucial tool that unlocks the upper echelon of 5G performance by solving its most fundamental thermal constraint.

Summary Table:

| Diamond's Role in 5G | Key Benefit | Impact on 5G System |

|---|---|---|

| Thermal Conductor | Highest thermal conductivity of any bulk material | Prevents overheating in high-power components |

| Substrate Material | Efficiently pulls heat from GaN transistors | Enables higher power density and stable operation |

| Performance Enabler | Solves the core thermal bottleneck | Allows 5G to achieve full potential for speed and range |

Push the Limits of Your 5G Technology with KINTEK's Advanced Thermal Solutions

Is thermal management the bottleneck holding back your high-frequency 5G components? Our expertise in high-temperature materials and precision manufacturing is directly applicable to the challenges of next-generation electronics.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions crucial for developing and testing materials like synthetic diamond. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements for materials research, including those for advanced thermal management substrates.

Let's solve your thermal challenges together. Contact our experts today to discuss how our solutions can enhance your 5G R&D and manufacturing processes.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

People Also Ask

- What limitations does CVD have in coating large surfaces? Overcome Scale Challenges with Custom Solutions

- What are the uses of chemical vapour deposition? Powering Modern Tech from Chips to Solar Panels

- How does the availability of specialized furnace systems benefit chemical research? Optimize Your Thermal Processing

- What are the key properties of diamond that make it a promising semiconductor material? Unlock Next-Gen Electronics

- How does a CVD machine work? Master the Technology for High-Quality Thin Film Deposition