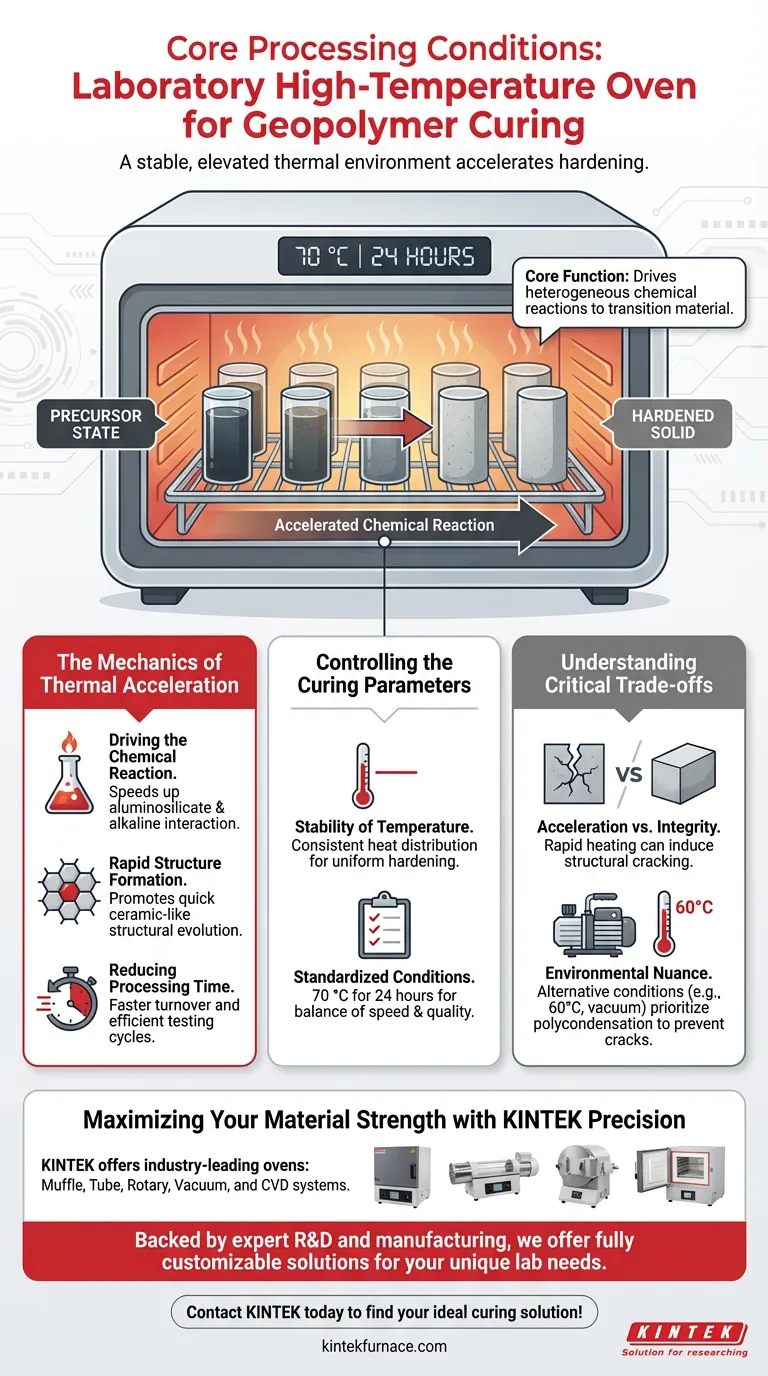

A laboratory high-temperature oven provides a stable, elevated thermal environment designed to accelerate the hardening process of geopolymer specimens. By maintaining specific conditions—typically 70 °C for a duration of 24 hours—the oven drives the necessary chemical reactions to transition the material from a precursor state to a hardened solid.

The core function of this thermal processing is to accelerate the heterogeneous chemical reaction between aluminosilicate precursors and alkaline solutions. This controlled heat treatment rapidly develops a ceramic-like structure, significantly reducing the time required for the material to reach its design strength.

The Mechanics of Thermal Acceleration

Driving the Chemical Reaction

The fundamental purpose of the oven is to provide the thermal energy required to speed up the heterogeneous chemical reaction.

Without this added heat, the interaction between the aluminosilicate precursors and the alkaline activators would proceed much slower.

Rapid Structure Formation

The elevated temperature promotes the quick formation of a rigid, ceramic-like structure.

This structural evolution is critical for transforming the raw chemical mixture into a cohesive solid capable of bearing loads.

Reducing Processing Time

By optimizing the curing environment, the oven significantly reduces the time to design strength.

This allows for faster turnover of specimens and more efficient testing cycles compared to ambient temperature curing.

Controlling the Curing Parameters

Stability of Temperature

The defining feature of laboratory-grade equipment is the ability to provide a stable thermal environment.

Consistent heat distribution is vital to ensure that the hardening process occurs uniformly throughout the specimen volume.

Standardized Conditions

A common and effective processing baseline involves maintaining the specimen at 70 °C for 24 hours.

This specific time-temperature combination is widely used to achieve a balance between reaction speed and material quality.

Understanding Critical Trade-offs

Acceleration vs. Integrity

While heat accelerates strength gain, the method of heating matters.

Rapid temperature increases can induce stress within the material, potentially leading to structural cracking.

Environmental nuance

While a standard high-temperature oven targets 70 °C for strength, other variations (such as vacuum drying ovens) may utilize slightly lower temperatures (e.g., 60 °C).

These alternative environments prioritize the three-dimensional polycondensation process to prevent cracks and ensure a smooth transition from liquid resin to a nanoporous solid.

Optimizing Your Curing Strategy

To select the right processing conditions, you must weigh the need for speed against the need for microstructural perfection.

- If your primary focus is rapid strength development: Utilize a standard high-temperature oven at 70 °C for 24 hours to accelerate the formation of the ceramic-like structure.

- If your primary focus is preventing structural defects: Consider slightly lower temperatures or controlled environments to manage the polycondensation process and minimize cracking risks.

Controlled thermal processing is the decisive factor that transforms reactive chemical precursors into a durable, high-performance geopolymer.

Summary Table:

| Curing Parameter | Standard Condition | Impact on Geopolymer |

|---|---|---|

| Temperature | 70 °C | Accelerates heterogeneous chemical reactions |

| Duration | 24 Hours | Rapidly develops ceramic-like structure and strength |

| Stability | Constant Heat | Ensures uniform hardening and structural integrity |

| Alternative | 60 °C (Vacuum) | Prioritizes polycondensation to minimize cracking |

Maximize Your Material Strength with KINTEK Precision

Ready to transform your precursors into high-performance solids? KINTEK offers industry-leading laboratory high-temperature ovens, including Muffle, Tube, Rotary, Vacuum, and CVD systems, specifically engineered for precise thermal processing. Whether you need rapid strength development or delicate polycondensation control, our equipment provides the stable thermal environment required for superior geopolymer integrity.

Backed by expert R&D and manufacturing, we offer fully customizable solutions for your unique lab needs.

Contact KINTEK today to find your ideal curing solution!

Visual Guide

References

- Marios Valanides, Demetris Nicolaides. Geopolymerization of Recycled Glass Waste: A Sustainable Solution for a Lightweight and Fire-Resistant Material. DOI: 10.3390/recycling9010016

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why are automated Mass Flow Controllers (MFCs) essential in mixed-gas nitriding? Achieve Process Precision

- Why is precise nitrogen flow critical for AlN nanofibers? Mastering High-Performance Nitridation Results

- What is the function of wet ball milling in the synthesis of SPAN? Optimize Your Sulfur Content Through Deep Mixing

- What are the advantages of SLRP compared to traditional high-temperature furnaces? Revolutionizing UHTC Coatings

- What is the primary function of glass matrices in HLW vitrification? Achieve Safe Radioactive Waste Immobilization

- What functions does ammonia (NH3) perform beyond acting as a nitrogen source? Unlock Advanced Surface Engineering

- What are the advantages of using a vacuum drying oven for BiVO4/COF composite photoanodes? Preserve Material Integrity

- Why must the filling of the working medium into a sodium heat pipe be performed inside a protective glovebox?