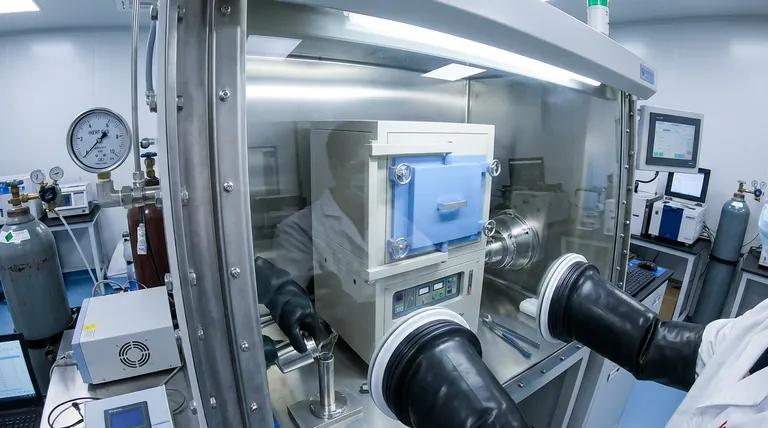

The filling of a sodium heat pipe must be conducted in a glovebox because metallic sodium is an extremely reactive alkali metal that poses immediate safety and performance risks when exposed to standard atmosphere. By utilizing an inert gas environment, you effectively isolate the sodium from oxygen and moisture, preventing violent chemical reactions and ensuring the working fluid remains pure.

Core Takeaway The glovebox environment serves two critical functions: it eliminates the risk of violent combustion caused by atmospheric moisture and prevents the formation of oxide impurities that would compromise the heat pipe's long-term chemical stability.

The Chemical Necessity of Isolation

Reactivity with Oxygen

Metallic sodium has a high affinity for oxygen. Upon contact with air, it oxidizes rapidly, degrading the quality of the metal instantly.

Reactivity with Moisture

The most significant danger lies in sodium's reaction with water vapor present in the atmosphere. This reaction is violent and exothermic, posing a severe physical hazard to the operator and the equipment.

The Role of Inert Gas

Flling the glovebox with an inert gas creates a barrier between the sodium and the environment. This effectively neutralizes the threat of oxidation and hydration during the delicate filling process.

Impact on Heat Pipe Performance

Preserving Purity

For a sodium heat pipe to function correctly, the working medium must be chemically pure. Even trace amounts of oxidation can introduce impurities into the system.

Ensuring Long-Term Stability

The primary reference highlights that chemical stability is essential for the device's operational life. Conducting the filling process in a protected environment ensures that the sodium retains its original properties, preventing degradation over years of use.

The Risks of Inadequate Protection

Safety Hazards

Attempting to handle metallic sodium outside of a controlled, inert environment is a major safety violation. The resulting reaction with ambient moisture can lead to fires or small-scale explosions.

Irreversible Contamination

If the sodium is exposed to air even briefly, oxides form that cannot be easily removed. These contaminants can clog the heat pipe's internal structures or alter the thermal properties of the working fluid, rendering the device inefficient or useless.

Ensuring Process Integrity

If your primary focus is Safety:

Ensure the glovebox maintains a positive pressure of inert gas to prevent any atmospheric leakage that could trigger a violent reaction.

If your primary focus is Device Longevity:

Prioritize the purity of the inert gas source to guarantee zero oxidation, as this directly correlates to the chemical stability of the heat pipe over time.

Strict adherence to this isolation protocol is the only way to guarantee both operator safety and the thermal reliability of the final product.

Summary Table:

| Factor | Atmospheric Risk | Glovebox Benefit |

|---|---|---|

| Chemical Reaction | Violent, exothermic reaction with moisture | Stable, non-reactive environment |

| Medium Purity | Rapid oxidation and contamination | Preserves 100% sodium purity |

| Operator Safety | High risk of fire or explosion | Safe, isolated handling process |

| Device Life | Reduced stability and efficiency | Guaranteed long-term thermal performance |

Secure Your High-Temperature Research with KINTEK

Handling reactive materials like sodium requires precision and safety. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable for your unique laboratory needs. Whether you are developing advanced heat pipes or conducting complex thermal experiments, our equipment provides the stability and control your project demands.

Ready to elevate your thermal processing capabilities? Contact KINTEK today to discuss your custom furnace solution!

References

- Shuaijie Sha, Junjie Wang. Experimental and numerical simulation study of sodium heat pipe with large aspect ratio. DOI: 10.2298/tsci231030059s

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the technical advantages of using a pyrolysis furnace vs. an incinerator? Recover Value from Composites

- What is the function of a high-temperature heating reactor in OPF delignification? Unlock High-Purity Cellulose

- What role does a vacuum oven play in determining the moisture content of mercury-depleted coal adsorbents? Key Insights

- What role do high-temperature sintering furnaces play in ceramic SLA? Unlock 99% Density in 3D Printed Ceramics

- Why Use a Vacuum Drying Oven for Ti3C2 MXene@NiS or Co4S3? Prevent Oxidation and Preserve Catalyst Integrity

- How does temperature control in carbonization furnaces affect structural battery anodes? Optimize Fiber Performance

- Why is annealing in a heat treatment furnace performed on graphite flake/copper composite samples before performance testing? Ensure Data Integrity for Precision Thermal Expansion Measurements

- What are the technical advantages of using a flux-coated filler metal with 20% silver? Optimize Cost & Joint Integrity