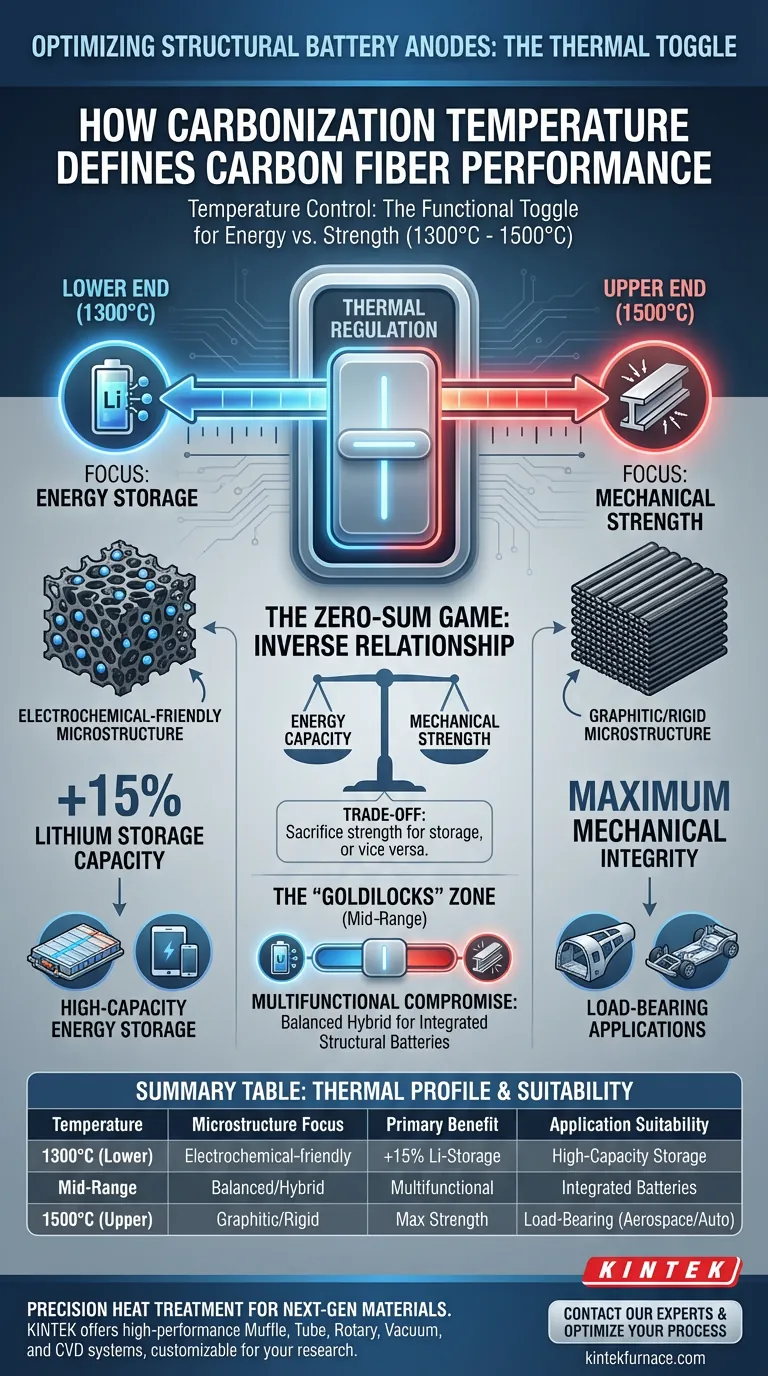

Temperature control acts as the functional toggle that determines whether a carbon fiber acts primarily as a load-bearing beam or an energy storage device. Within a high-temperature carbonization furnace, specifically between 1300°C and 1500°C, the chosen heat profile directly regulates the fiber's microstructure. Operating at the lower end of this high-temperature range can increase electrochemical lithium storage capacity by approximately 15 percent, while increasing the temperature prioritizes mechanical rigidity over storage capability.

In structural battery design, thermal processing is a zero-sum game: you must sacrifice some mechanical strength to gain energy capacity, or vice versa, by manipulating the furnace temperature within the critical 1300°C to 1500°C window.

The Impact of Thermal Regulation on Microstructure

To create multifunctional carbon fibers—materials that serve as both the chassis and the battery anode—you must control the furnace environment with extreme precision. The heat profile dictates how the internal carbon structure forms.

The Critical Temperature Range

The primary lever for this control is the temperature setting between 1300°C and 1500°C.

This specific window is where the carbon fiber transitions from a precursor state into a graphitic structure suitable for high-performance applications.

Defining the Fiber's Purpose

The furnace does not just "bake" the fiber; it defines its identity.

By adjusting the temperature profile, you are effectively programming the fiber's microstructure to excel in one specific domain of physics: mechanics or electrochemistry.

Understanding the Trade-offs

The most critical insight for an engineer is understanding the inverse relationship between stiffness and storage. You cannot maximize both simultaneously using temperature control alone.

Optimizing for Energy Density

When the furnace operates at the lower end of the high-temperature spectrum, the microstructure retains features beneficial for lithium-ion interaction.

This specific thermal profile yields a significant advantage: an approximate 15 percent increase in electrochemical lithium storage capacity.

Optimizing for Structural Integrity

Conversely, pushing the furnace temperature toward the 1300°C–1500°C upper limit forces the microstructure to align more rigidly.

This results in enhanced mechanical strength, making the fiber capable of bearing significant structural loads, which is essential for vehicle bodies or aerospace frames.

The Balancing Act

The challenge in producing structural battery anodes is finding the "Goldilocks" zone.

You must accept that high mechanical performance will limit the battery's range, while high energy capacity will reduce the structural load the material can safely support.

Making the Right Choice for Your Goal

Selecting the correct temperature profile depends entirely on the performance requirements of your specific application.

- If your primary focus is Energy Storage: Prioritize lower-range high-temperature profiles to capitalize on the 15 percent gain in lithium capacity.

- If your primary focus is Load Bearing: Target the higher end of the 1300°C–1500°C range to maximize tensile strength and structural reliability.

- If your primary focus is Multifunctionality: Aim for a mid-range temperature that provides a calculated compromise, offering sufficient strength for the structure while maintaining viable battery capacity.

Mastering this thermal variable empowers you to engineer a material that truly serves a dual purpose.

Summary Table:

| Temperature Range | Microstructure Focus | Primary Benefit | Application Suitability |

|---|---|---|---|

| 1300°C (Lower End) | Electrochemical-friendly | +15% Lithium storage capacity | High-capacity energy storage |

| Mid-Range | Balanced/Hybrid | Multifunctional compromise | Integrated structural batteries |

| 1500°C (Upper End) | Graphitic/Rigid | Maximum mechanical strength | Load-bearing aerospace & auto |

| Trade-off | Inverse Relationship | Strength vs. Storage | Engineering specific goals |

Precision Heat Treatment for Next-Gen Materials

Achieving the perfect balance between mechanical rigidity and energy density requires absolute thermal control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet the rigorous demands of carbon fiber carbonization and structural battery research.

Ready to optimize your carbonization process? Contact our engineering experts today to find the ideal lab high-temp furnace for your unique material needs.

Visual Guide

References

- Ruben Tavano, E. Leif. Influence of Carbonisation Temperatures on Multifunctional Properties of Carbon Fibres for Structural Battery Applications. DOI: 10.1002/batt.202400110

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why is high-temperature stability important for Cu2O substrates? Ensure Long-Term Electrocatalytic Efficiency

- What role does Sodium Chloride (NaCl) play as a thermal buffer? Optimizing Si/Mg2SiO4 Composite Synthesis

- Why is a forced air circulation oven required for Al-Cu-Mn alloy aging? Achieve Peak Hardness with Uniform Heat

- What is the function of a laboratory vacuum drying oven for Fe-N-C catalysts? Preserve Nanoporous Structure

- Why must calcination equipment be used to pre-treat ZSM-5 zeolite? Ensure Accurate VOC Adsorption Testing

- What are some examples of low-temperature industrial heating processes? Boost Efficiency and Sustainability

- Why is a high-precision high-temperature furnace required for mechanical testing? Secure Reliable Material Data

- How does the catalytic steam reforming system convert refinery waste gas into syngas for SOFC? Maximize Waste Energy