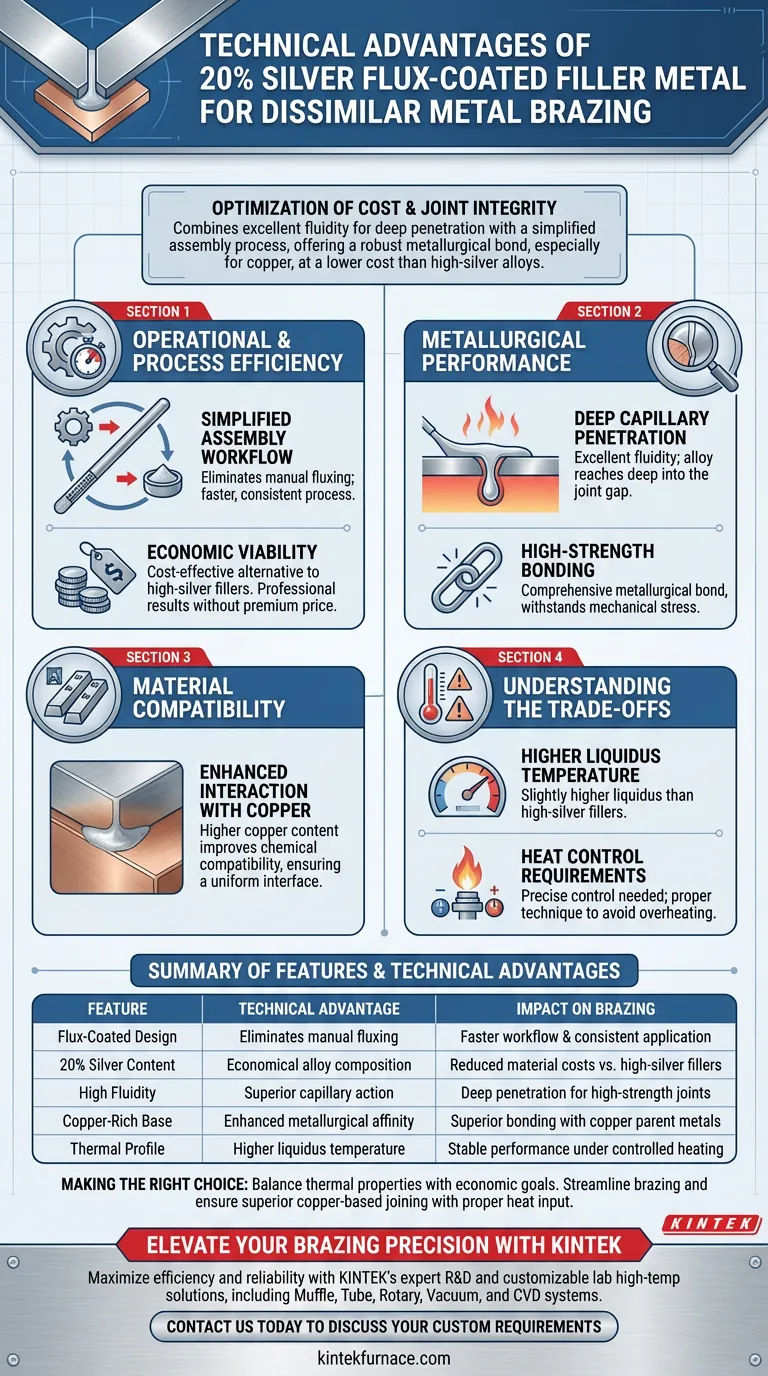

The primary technical advantage of using a flux-coated filler metal with 20% silver is the optimization of both cost and joint integrity in dissimilar metal brazing. This filler metal combines excellent fluidity for deep joint penetration with a simplified assembly process due to the pre-placed flux. It provides a robust metallurgical bond, specifically enhancing compatibility with copper parent metals while offering a more economical alternative to high-silver alloys.

By eliminating separate flux application and leveraging higher copper content for better base metal compatibility, this filler creates a streamlined, high-strength solution for complex joining applications.

Operational and Process Efficiency

Simplified Assembly Workflow

The flux-coated design significantly reduces preparation time by eliminating the need for manual flux application. By pre-placing the flux directly on the filler surface, the assembly process becomes faster and less prone to operator inconsistency.

Economic Viability

Using a 20% silver content provides a cost-effective alternative to high-silver fillers. It delivers professional-grade results and efficiency without the premium price tag associated with higher silver concentrations.

Metallurgical Performance

Deep Capillary Penetration

When heated by a torch, this filler metal demonstrates excellent fluidity. This characteristic allows the alloy to utilize capillary action effectively, reaching deep into the joint gap rather than merely sitting on the surface.

High-Strength Bonding

The deep penetration capability ensures a comprehensive metallurgical bond. This results in a high-strength joint capable of withstanding mechanical stress, which is critical when joining metals with different properties.

Material Compatibility

Enhanced Interaction with Copper

Because this filler contains 20% silver, the remaining composition includes a higher percentage of copper compared to high-silver alternatives. This increased copper content improves the filler's chemical compatibility with copper parent metals, ensuring a more uniform and reliable interface.

Understanding the Trade-offs

Higher Liquidus Temperature

It is essential to recognize that this filler metal has a slightly higher liquidus temperature than high-silver fillers.

Heat Control Requirements

Due to this higher temperature threshold, operators must exercise precise control during torch heating. Proper technique is required to ensure the filler flows correctly without overheating or distorting the base materials.

Making the Right Choice for Your Project

Selecting the correct filler requires balancing thermal properties with economic goals.

- If your primary focus is operational efficiency: Choose this filler to streamline the brazing process and eliminate the step of separate flux application.

- If your primary focus is copper-based joining: Leverage the higher copper content to ensure superior chemical compatibility and bonding with copper parent metals.

By mastering the heat input required for this alloy, you achieve a durable, professional joint that balances performance with economy.

Summary Table:

| Feature | Technical Advantage | Impact on Brazing |

|---|---|---|

| Flux-Coated Design | Eliminates manual fluxing | Faster workflow & consistent application |

| 20% Silver Content | Economical alloy composition | Reduced material costs vs. high-silver fillers |

| High Fluidity | Superior capillary action | Deep penetration for high-strength joints |

| Copper-Rich Base | Enhanced metallurgical affinity | Superior bonding with copper parent metals |

| Thermal Profile | Higher liquidus temperature | Stable performance under controlled heating |

Elevate Your Brazing Precision with KINTEK

Maximize operational efficiency and joint reliability with materials designed for performance. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab high-temp solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique metallurgical needs.

Whether you are joining dissimilar metals or optimizing high-temp workflows, our team is ready to provide the technical expertise you deserve. Contact us today to discuss your custom requirements!

Visual Guide

References

- Auday Awad Abtan, Iqbal Alshalal. Microstructure, Mechanical Properties, and Heat Distribution ANSYS model of CP Copper and 316 Stainless Steel Torch Brazing. DOI: 10.12913/22998624/177299

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What technical requirements are placed on heating equipment for fast pyrolysis? Master High-Yield Bio-Oil Production

- How do high-temperature annealing furnaces ensure equilibrium in Bi2Se3-Nd2Se3 alloys? Expert Thermal Control Solutions

- What task does a laboratory blast drying oven perform in the preparation of copper oxide precursors? Prevent Clumping

- What is the purpose of employing Ozone (O3) treatment following the AS-ALD of Al2O3? Boost Film Purity and Density

- Why is the selection of electrode materials critical for the Plasma Flash Sintering (PFS) of titanium dioxide samples?

- What is the primary function of a forced air oven in SnmCunOx-t synthesis? Master Chemical Foaming

- What is the primary function of an electric furnace in PBG melting? Expert Guide to Thermal Homogeneity

- What is the function of a precision laboratory oven in KNN ceramic pretreatment? Ensure Stoichiometric Accuracy