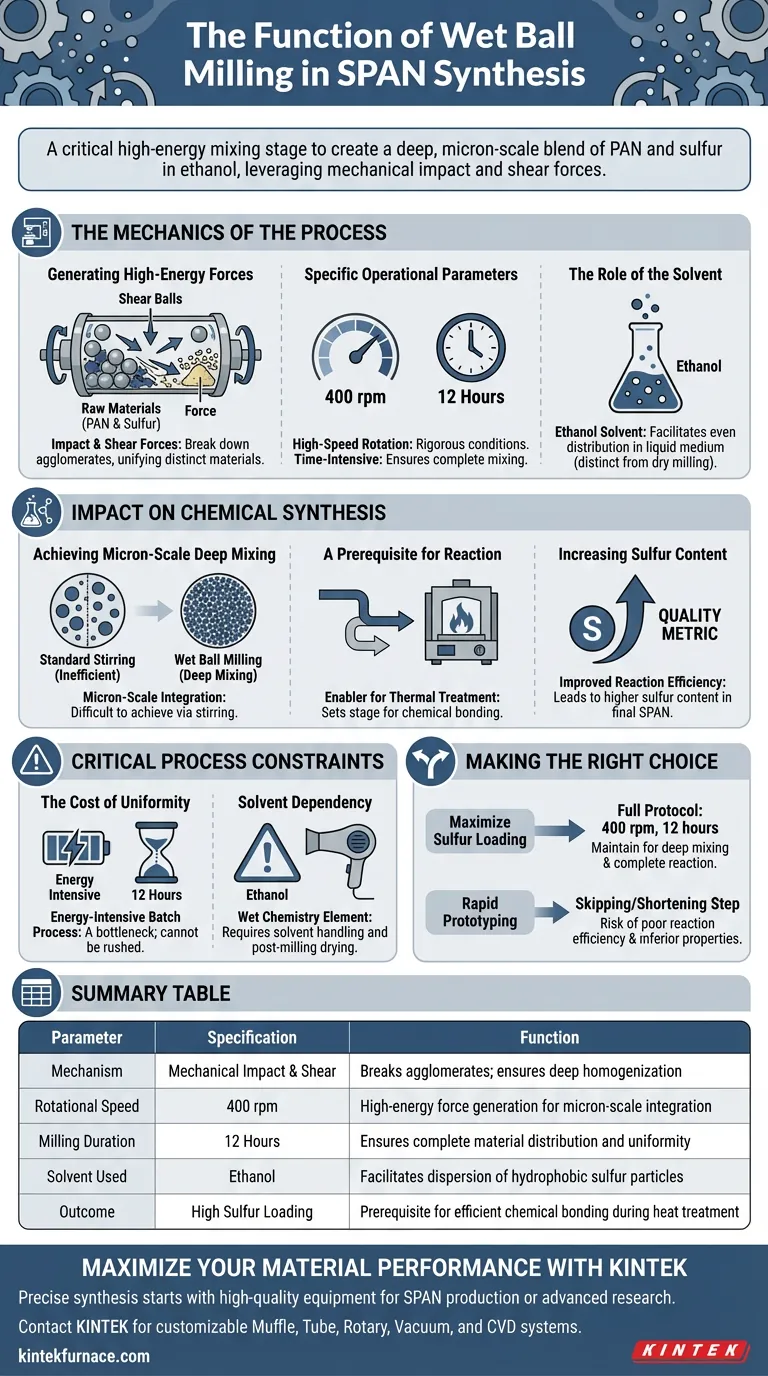

Wet ball milling functions as a critical high-energy mixing stage in the synthesis of sulfurized polyacrylonitrile (SPAN), specifically designed to create a deep, micron-scale blend of raw materials. By subjecting polyacrylonitrile (PAN) and sulfur to high-speed rotation within an ethanol solvent, the process leverages mechanical impact and shear forces to ensure the components are intimately mixed before thermal processing.

The primary purpose of this step is to establish the necessary physical proximity between reactants; without this high-energy homogenization, the subsequent thermal treatment cannot achieve the sufficient reaction between sulfur and polymer chains required for high sulfur content.

The Mechanics of the Process

Generating High-Energy Forces

The core mechanism of wet ball milling relies on the physical interaction between the grinding balls and the raw materials.

As the device rotates, the grinding balls generate significant impact and shear forces. These forces physically break down agglomerates and force the distinct materials into a unified mixture.

Specific Operational Parameters

To be effective, this process requires rigorous conditions rather than gentle stirring.

Standard protocols often utilize high-speed rotation, such as 400 rpm. Furthermore, the process is time-intensive, typically requiring durations around 12 hours to ensure the mixing is complete.

The Role of the Solvent

This process is distinct from dry milling because it takes place within a liquid medium.

Ethanol is used as the solvent for the PAN and sulfur mixture. This fluid medium facilitates the even distribution of the solid particles during the grinding phase.

Impact on Chemical Synthesis

Achieving Micron-Scale Deep Mixing

The ultimate goal of the mechanical forces described above is "deep mixing."

This goes beyond simple blending; it achieves a micron-scale integration of the sulfur and PAN. This level of homogeneity is difficult to achieve through standard stirring methods.

A Prerequisite for Reaction

Wet ball milling is not merely a physical shaping step; it is a chemical enabler.

It acts as a critical prerequisite for the subsequent thermal treatment. By ensuring the raw materials are deeply mixed, it sets the stage for the chemical bonding process that follows.

Increasing Sulfur Content

The efficiency of the physical mix directly dictates the quality of the final material.

Because the sulfur and polymer chains are brought into such close contact, the reaction is more complete. This leads directly to an increase in sulfur content within the final SPAN material, which is the primary metric of quality for these composites.

Critical Process Constraints

The Cost of Uniformity

While wet ball milling guarantees a better mix, it introduces specific constraints regarding time and energy.

The requirement for a 12-hour duration at high speeds indicates that this is an energy-intensive batch process. It is a bottleneck that cannot be easily rushed without compromising the material structure.

Solvent Dependency

The use of ethanol introduces a wet chemistry element to the grinding.

This requires appropriate handling of the solvent and likely necessitates a drying step post-milling. However, this complexity is the trade-off required to achieve the necessary dispersion of hydrophobic sulfur with the polymer.

Making the Right Choice for Your Goal

The use of wet ball milling is determined by your specific requirements for material quality versus process speed.

- If your primary focus is maximizing sulfur loading: You must maintain the full 12-hour, 400 rpm milling protocol to ensure the deep mixing required for a complete reaction.

- If your primary focus is rapid prototyping: Be aware that skipping or shortening this micron-scale mixing step will likely result in poor reaction efficiency and inferior material properties.

Detailed mechanical preparation is the unavoidable foundation for high-performance chemical synthesis in SPAN materials.

Summary Table:

| Parameter | Specification | Function |

|---|---|---|

| Mechanism | Mechanical Impact & Shear | Breaks agglomerates; ensures deep homogenization |

| Rotational Speed | 400 rpm | High-energy force generation for micron-scale integration |

| Milling Duration | 12 Hours | Ensures complete material distribution and uniformity |

| Solvent Used | Ethanol | Facilitates dispersion of hydrophobic sulfur particles |

| Outcome | High Sulfur Loading | Prerequisite for efficient chemical bonding during heat treatment |

Maximize Your Material Performance with KINTEK

Precise synthesis starts with high-quality equipment. Whether you are scaling up SPAN production or conducting advanced lab research, KINTEK provides the tools you need for success. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique thermal processing requirements.

Don't let inefficient mixing or inconsistent heating limit your results. Contact our specialists today to find the perfect furnace solution for your synthesis workflow!

Visual Guide

References

- Krishna Kumar Sarode, Vibha Kalra. Solid–liquid–solid mediated artificial SEI coated stable lithium and high-sulfur percentage SPAN for high performance Li–S batteries. DOI: 10.1039/d3ya00423f

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

People Also Ask

- Why is a stainless steel autoclave with a Teflon liner necessary for BiVO4? Ensure Purity & High Performance

- Why is the addition of silver nanoparticles critical for Ag2Se films? Unlock High Thermoelectric Performance

- What are the advantages of using a customized multimode microwave reaction furnace? Boost Synthesis Speed by 90%

- How does a bias power supply influence AlCrSiWN coatings? Master Ion Bombardment for Superior Durability

- What are the primary functions of high-purity nitrogen flow in carbon pyrolysis? Optimize Purity and Pore Structure

- What is the purpose of coating aluminum electrodes with Au80Pd20? Enhancing Precision in Nanoparticle Characterization

- What are the advantages of using microwave drying equipment for organic gels? Preserve Pore Structures Effectively

- What type of laboratory equipment is utilized for the high-temperature synthesis of g-C3N4? Key Tools for Success