The primary function of borosilicate or aluminophosphate glass matrices is to act as a solidification carrier for high-level radioactive waste (HLW). These matrices utilize an amorphous network structure to encapsulate radionuclides, locking them within a chemically stable solid body. This transformation is critical for preventing the release of radioactive materials into the environment.

The core purpose of these matrices is to lower biological toxicity by trapping volatile radioactive elements within a durable, disordered atomic framework. This ensures the waste remains isolated and stable during long-term deep geological disposal.

The Mechanics of Immobilization

Function as a Solidification Carrier

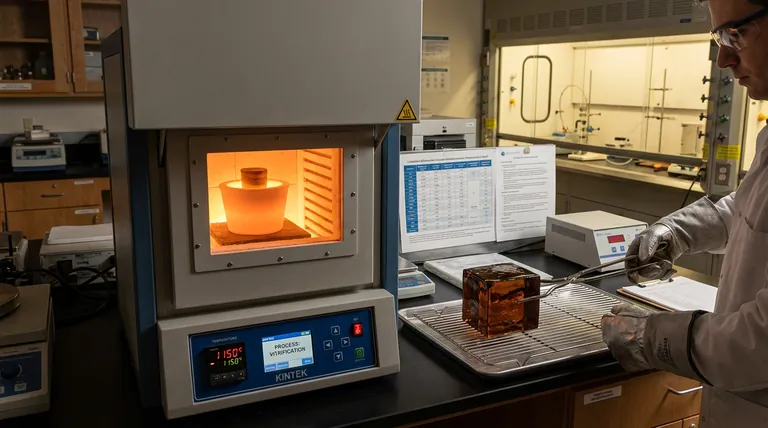

In the vitrification process, the glass matrix serves as the host medium. It physically and chemically incorporates the radioactive waste components into a unified solid form.

The Role of Amorphous Network Structure

Unlike crystalline materials, these glasses possess a disordered, amorphous network structure. This structural flexibility allows the matrix to accommodate a wide variety of radionuclides within its atomic framework.

Encapsulation of Radionuclides

The process does not merely surround the waste; it locks radionuclides into the glass structure. This ensures that radioactive elements are an integral part of the final product, rather than loose inclusions.

Strategic Objectives of Vitrification

Ensuring Chemical Stability

The glass matrix is engineered to be chemically stable. This durability is essential to resist corrosion and degradation over the vast timeframes required for radioactive decay.

Lowering Biological Toxicity

By converting liquid or sludge waste into a stable solid, the matrix significantly reduces the immediate biological hazard. This makes the waste safer to handle, transport, and store.

Facilitating Deep Geological Disposal

The ultimate destination for HLW is deep geological repositories. The vitrified glass form is specifically designed to withstand these subterranean environments without releasing its radioactive payload.

Critical Requirements for Success

Stability Over Time

The effectiveness of the matrix relies entirely on its long-term resistance to environmental factors. If the glass matrix degrades prematurely, the encapsulated radionuclides could migrate into the surrounding geology.

Material Integrity

The "locking" mechanism must be absolute. Any failure in the amorphous network to fully integrate the radionuclides compromises the safety of the entire disposal strategy.

Evaluating the Vitrification Approach

To determine the effectiveness of a waste management strategy, consider the following objectives:

- If your primary focus is environmental protection: Ensure the glass matrix chosen offers maximum chemical stability to prevent leaching during deep geological storage.

- If your primary focus is waste processing: Value the amorphous structure of the matrix for its ability to accept and solidify diverse radionuclide streams.

The glass matrix serves as the fundamental barrier that secures high-level waste against environmental release.

Summary Table:

| Feature | Function in Vitrification | Impact on Safety |

|---|---|---|

| Amorphous Network | Flexible structural framework | Accommodates diverse radionuclides |

| Chemical Stability | Resists corrosion and leaching | Prevents environmental contamination |

| Solidification | Converts liquid/sludge to solid | Reduces biological toxicity and hazard |

| Physical Integrity | Locks elements in a unified body | Ensures stability for geological disposal |

Secure Your Lab’s High-Temperature Processing with KINTEK

Precise control and material integrity are vital when handling advanced materials and waste management research. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet your unique thermal processing needs.

Whether you are developing glass matrices for vitrification or performing critical material analysis, our lab high-temp furnaces provide the durability and stability you require.

Contact KINTEK today to find your custom solution!

References

- S. V. Yudintsev, V. I. Malkovsky. Thermal Effects and Glass Crystallization in Composite Matrices for Immobilization of the Rare-Earth Element–Minor Actinide Fraction of High-Level Radioactive Waste. DOI: 10.3390/jcs8020070

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra High Vacuum Observation Window KF Flange 304 Stainless Steel High Borosilicate Glass Sight Glass

- Ultra High Vacuum CF Flange Stainless Steel Sapphire Glass Observation Sight Window

- Ultra High Vacuum CF Observation Window Flange with High Borosilicate Glass Sight Glass

- Ultra High Vacuum Observation Window Stainless Steel Flange Sapphire Glass Sight Glass for KF

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

People Also Ask

- How does high-temperature substrate heating at 500 °C facilitate TiO2 formation? Enhance Film Density and Quality

- What are the energy-saving advantages of using a SHS system for tungsten carbide? Cut Energy Costs by up to 90%

- What heat treatment conditions are required for SDSS2507 solution treatment? Achieve Precise 1100°C Thermal Profiles

- What is the impact of temperature control precision on solution-cast films? Ensuring Integrity and Uniformity

- What are the benefits of using graphite or stainless steel crucibles for Rubidium Chloride? Ensure Maximum Purity

- Why is a multiple high-temperature tempering process necessary for high-cobalt steels? Achieve Peak Hardness & Stability

- What role do high-precision laboratory ovens play in assessing the energy potential of MSW? Enhancing Biomass Accuracy

- How does a high-precision temperature control system assist in evaluating the thermal management capabilities of phosphor materials? Pinpoint Performance for Solar Cells.