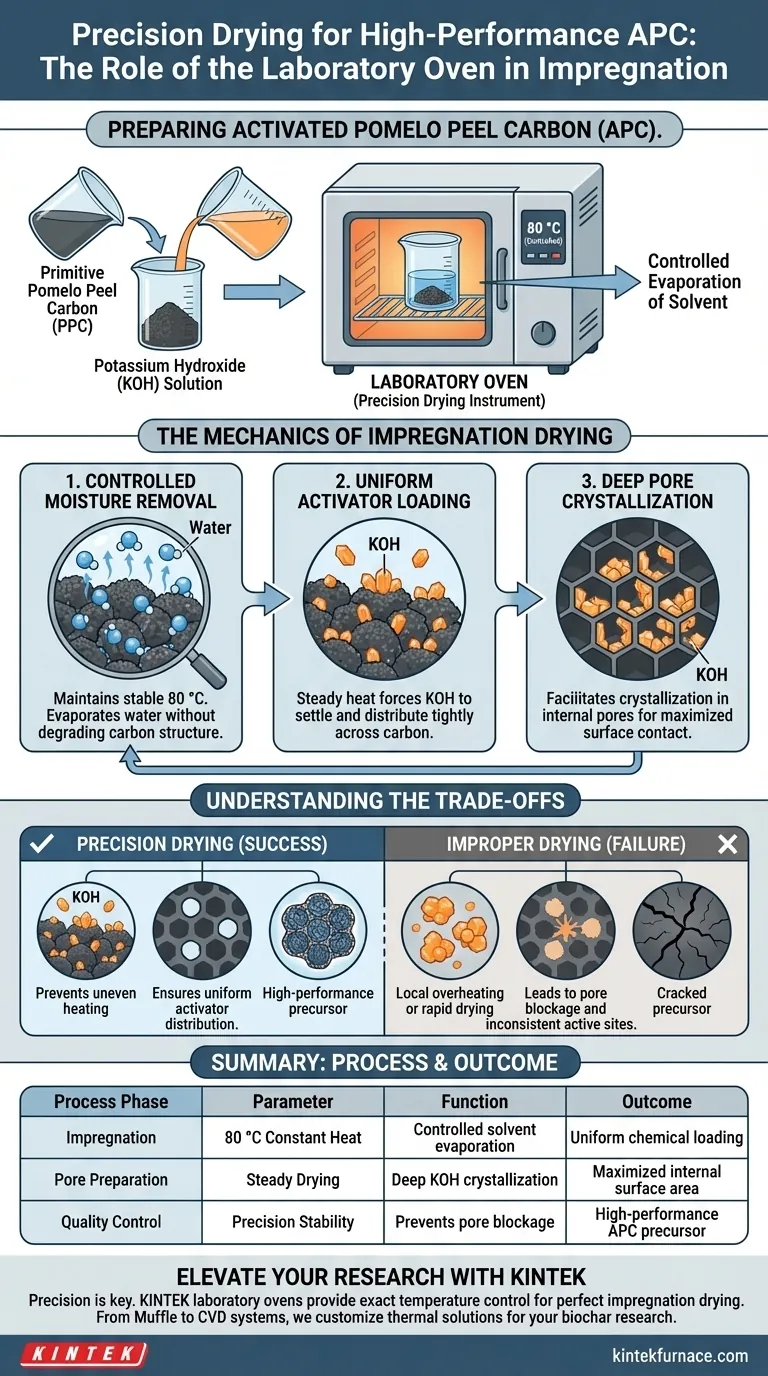

In the preparation of activated pomelo peel carbon (APC), the laboratory oven acts as a precision drying instrument during the critical impregnation phase. It is specifically employed to heat the mixture of primitive pomelo peel carbon (PPC) and potassium hydroxide (KOH) solution at a controlled temperature of 80 °C.

The primary function of the oven is to drive off moisture through smooth, controlled evaporation, ensuring the chemical activator (KOH) is uniformly loaded and crystallized within the biochar's pore structure prior to high-temperature activation.

The Mechanics of Impregnation Drying

Controlled Moisture Removal

The laboratory oven provides a stable thermal environment, maintaining the mixture at exactly 80 °C.

This specific temperature is sufficient to evaporate the solvent (water) without triggering premature chemical reactions or degrading the carbon structure.

Uniform Activator Loading

As the moisture evaporates, the oven’s steady heat forces the KOH activator to settle onto the carbon material.

Instead of pooling on the surface, the activator is tightly loaded and distributed evenly across the primitive carbon.

Deep Pore Crystallization

The drying process facilitates the crystallization of KOH not just on the surface, but deep within the pore structures of the biochar.

This deep penetration is vital, as it ensures the activating agent is in direct contact with the internal surface area of the carbon.

Understanding the Trade-offs

The Importance of Thermal Stability

Using a laboratory oven prevents the risks associated with uneven heating or rapid drying.

Local overheating can cause the solvent to boil violently rather than evaporate smoothly.

Risks of Improper Drying

If the temperature fluctuates or is set too high, the activator may distribute unevenly.

This can lead to pore blockage or the creation of inconsistent active sites, effectively ruining the material's potential performance during the subsequent high-temperature activation stage.

Optimization for Material Success

To ensure the highest quality activated pomelo peel carbon, consider the following based on your specific objectives:

- If your primary focus is Surface Area: Ensure the oven maintains a strict 80 °C to allow gradual crystallization, maximizing the activator's contact with the internal pore network.

- If your primary focus is Process Consistency: Use a precision constant temperature oven to prevent local overheating, ensuring every batch of APC has identical chemical loading.

The laboratory oven effectively transforms a simple wet mixture into a structurally prepared precursor ready for activation.

Summary Table:

| Process Phase | Parameter | Function | Outcome |

|---|---|---|---|

| Impregnation | 80 °C Constant Heat | Controlled solvent evaporation | Uniform chemical loading |

| Pore Preparation | Steady Drying | Deep KOH crystallization | Maximized internal surface area |

| Quality Control | Precision Stability | Prevents pore blockage | High-performance APC precursor |

Elevate Your Material Research with KINTEK

Precision is the difference between a blocked pore and a high-performance catalyst. At KINTEK, we understand that APC preparation requires unwavering thermal stability. Our laboratory ovens provide the exact temperature control needed for perfect impregnation drying.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces. Whether you are scaling up biochar production or developing custom carbon structures, our systems are fully customizable to meet your unique research needs.

Ready to optimize your activation process? Contact our experts today to find the perfect thermal solution for your laboratory.

Visual Guide

References

- Jing Gong, Baowei Hu. Honeycomb-structured biochar from waste pomelo peel for synergistic adsorptive and photocatalytic removal of Cr(VI). DOI: 10.1007/s44246-024-00174-5

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- 1200℃ Muffle Oven Furnace for Laboratory

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is a constant temperature drying oven used at 120°C for 16 hours for NiCuCe catalysts? Optimize Site Dispersion

- What is a continuous furnace? The High-Volume Solution for Efficient Thermal Processing

- What is the function of the 1500 °C environment in wood carbonization? Unlock High-Performance Functional Carbon

- What is the function of a drying oven in the post-treatment process of Ni and Zn-doped MgO nanoparticles?

- How does the perpendicular orientation of substrate holders benefit VTD? Maximize Efficiency and Thermal Control

- What is the function of a forced drying oven in SiOC coating conversion? Ensure Flawless Solvent Removal

- How is the graphitization degree quantified using Raman spectroscopy? Master the $I_D/I_G$ Ratio for Carbon Materials

- What functions do high-strength graphite molds perform during SPS? Drive Efficiency & Precision in Material Bonding