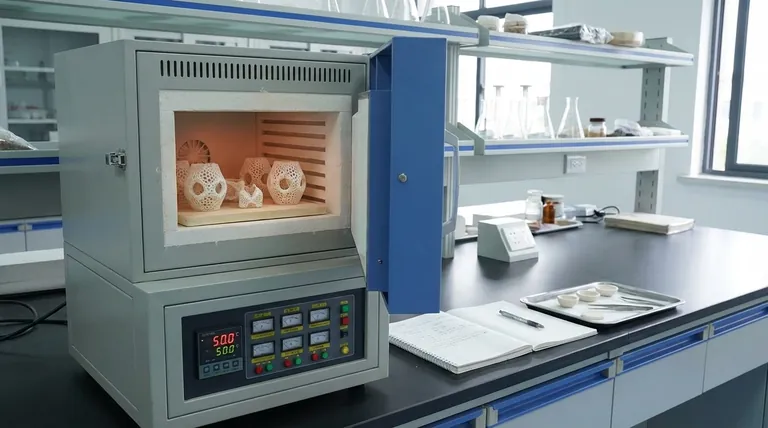

Precision drying is the specific safeguard against structural failure in ceramic processing. It is necessary to facilitate the slow, uniform removal of moisture from the slurry-coated green body. By utilizing equipment like constant temperature ovens at 50 °C, you prevent rapid evaporation that would otherwise destroy the delicate porous architecture.

The use of precision drying equipment ensures moisture is removed slowly and evenly, preventing uneven capillary pressure. This is the single most effective method for avoiding micro-cracks and deformation, guaranteeing the integrity of the complex porous skeleton.

The Mechanics of Moisture Removal

Controlling Evaporation Rates

The drying process involves treating the coated green body at a constant temperature of 50 °C. This phase can last for up to 12 hours.

This extended duration at a moderate temperature is intentional. It forces the moisture to exit the slurry at a gradual, controlled pace rather than flashing off quickly.

Ensuring Uniformity

Precision equipment, such as a drying cabinet, eliminates environmental fluctuations. It maintains a steady thermal environment around the entire geometry of the part.

This uniformity ensures that one section of the skeleton does not dry—and consequently shrink—faster than another.

The Science of Defect Prevention

Managing Capillary Pressure

The root cause of failure during drying is uneven capillary pressure. When moisture evaporates too quickly, significant pressure differentials build up within the pores of the material.

Precision drying neutralizes this threat. By keeping the evaporation slow, capillary forces remain balanced throughout the structure.

Eliminating Micro-Cracks and Deformation

If capillary pressure is not managed, the stress manifests physically as micro-cracks or warping. These defects compromise the structural integrity of the skeleton.

Proper drying ensures the green body remains physically stable. This stability is a prerequisite for the ceramic to survive subsequent processing steps without falling apart.

Understanding the Trade-offs

The Cost of Patience

The primary "downside" of this method is time. Dedicating up to 12 hours for drying at a low temperature of 50 °C can create a bottleneck in high-speed production lines.

The Risk of Acceleration

Attempting to speed up this process is the most common cause of component loss. Increasing the temperature above the recommended range to save time triggers rapid evaporation.

This inevitably leads to the very deformation and cracking the equipment is designed to prevent. There is no shortcut that preserves the structural integrity of the porous skeleton.

Making the Right Choice for Your Goal

To ensure high yields and consistent quality in porous mullite ceramics, adhere to the following:

- If your primary focus is Structural Integrity: Strictly maintain the 50 °C temperature limit to prevent uneven capillary pressure.

- If your primary focus is Process Efficiency: Optimize your batch scheduling to accommodate the 12-hour cycle rather than increasing heat to shorten it.

Precision in drying is not an optional refinement; it is the fundamental requirement for a crack-free green body.

Summary Table:

| Parameter | Standard Requirement | Role in Process |

|---|---|---|

| Drying Temperature | 50 °C (Constant) | Prevents rapid evaporation & flash-off |

| Process Duration | Up to 12 Hours | Ensures gradual moisture removal |

| Key Mechanism | Capillary Pressure Control | Neutralizes internal stress & pressure differentials |

| Critical Outcome | Structural Integrity | Eliminates warping and micro-crack formation |

Elevate Your Material Integrity with KINTEK

Don't let structural failure compromise your research or production. KINTEK provides high-precision thermal solutions tailored for the delicate drying and sintering stages of advanced ceramics. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to maintain the exact 50 °C environment or high-temp profiles your unique porous skeletons require.

Ready to eliminate micro-cracks and maximize your yield?

Contact our laboratory experts today to find the perfect precision equipment for your workflow.

References

- Chunxia Xu, Wenbin Han. Research on preparation and related properties of macro–micro porous mullite ceramic skeletons <i>via</i> twice pore-forming technology. DOI: 10.1039/d4ra01277a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What technical advantages do high-temperature furnace systems provide for robust flexible interconnects? Enhance Durability

- What is sintering in the context of 3D printing? Unlock Dense, Functional Parts with Precision

- What are the benefits of using graphite or stainless steel crucibles for Rubidium Chloride? Ensure Maximum Purity

- What is the significance of industrial drying equipment for metal powders? Master Post-Processing & Quality Control

- What is the function of rapid quenching after high-temperature heat treatment? Master AlSi10Mg Microstructural Control

- What role does natural zeolite play as a catalyst in LDPE pyrolysis? Boost Yield and Efficiency in Plastic Recycling

- Why is the use of silver-containing active brazing alloys prohibited in TEGs? Prevent Semiconductor Degradation

- How does a high-temperature annealing furnace regulate cold-rolled steel? Optimize Manganese Steel Performance