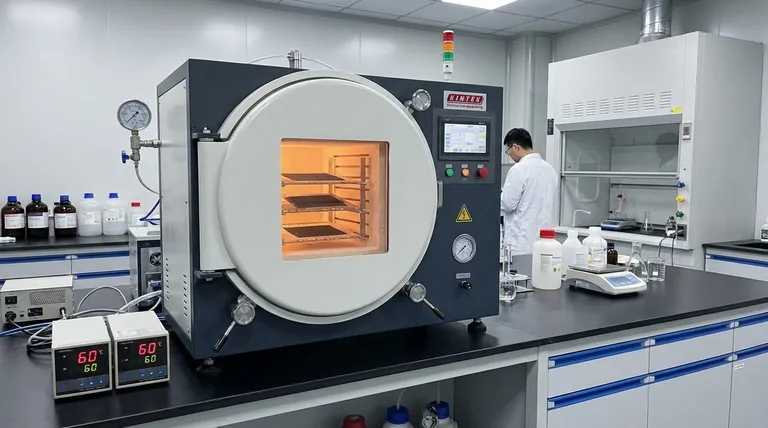

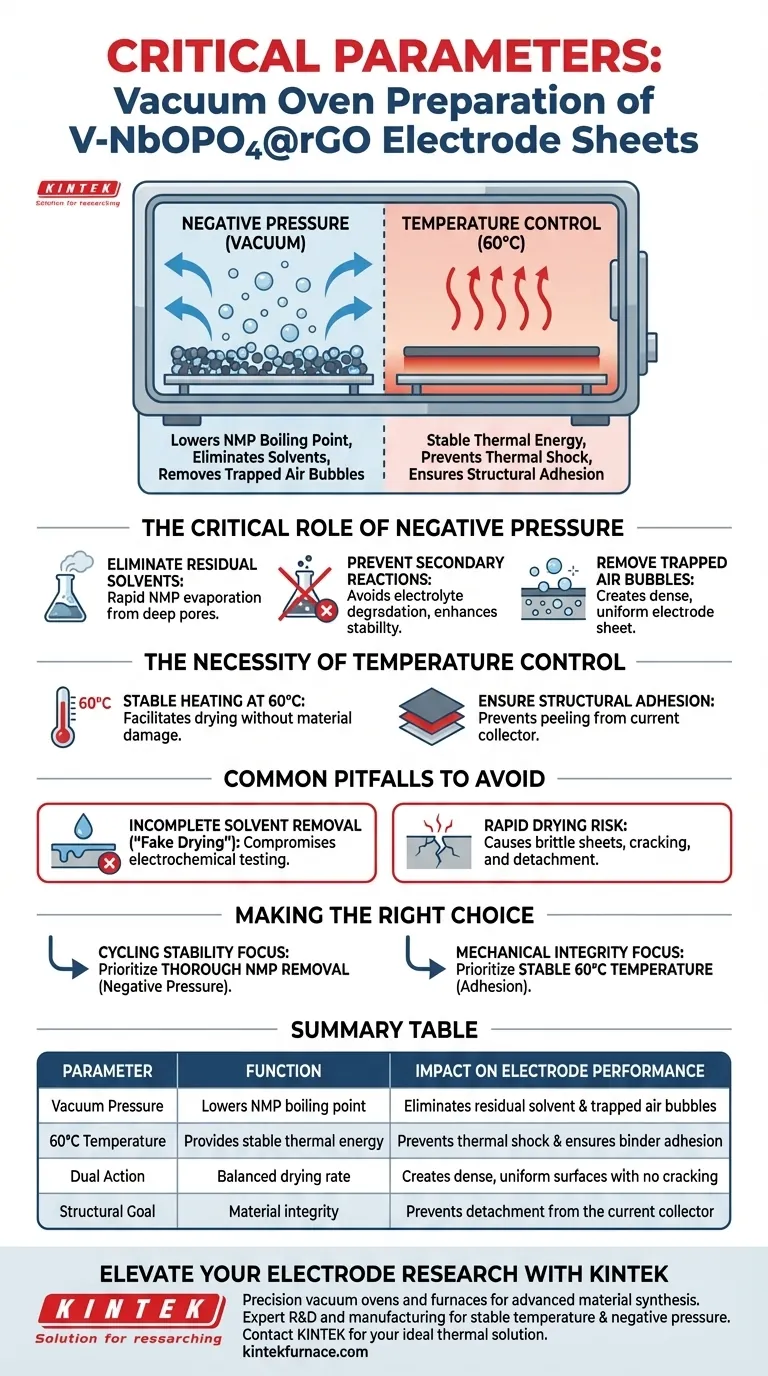

Precise temperature regulation and vacuum pressure are essential to completely eliminate residual N-methyl-pyrrolidone (NMP) solvent and trapped air bubbles from the electrode coating. By maintaining a stable 60°C environment under negative pressure, you ensure the structural integrity of the V-NbOPO4@rGO sheets and prevent detrimental chemical reactions during battery operation.

The vacuum oven aligns thermal energy with low pressure to maximize solvent extraction without damaging the material. This dual action creates a dense, uniform electrode surface that adheres securely to the collector, directly enabling stable electrochemical performance.

The Critical Role of Negative Pressure

Eliminating Residual Solvents

The primary function of the vacuum environment is to lower the boiling point of solvents, specifically N-methyl-pyrrolidone (NMP).

Under normal atmospheric pressure, removing NMP from the deep pores of the electrode material is difficult and slow. Negative pressure forces the rapid and thorough evaporation of this solvent.

Preventing Secondary Reactions

Removing NMP is not just about drying; it is about chemical stability.

If residual NMP remains in the electrode, it can trigger secondary reactions during battery cycling. These reactions degrade the electrolyte and the active material, significantly reducing the battery's lifespan and efficiency.

removing Trapped Air Bubbles

During the coating process, microscopic air bubbles can become trapped within the slurry.

The vacuum environment actively pulls these bubbles out of the coating. This results in a dense electrode sheet with uniform consistency, which is vital for reliable electron transport.

The Necessity of Temperature Control

Stable Heating at 60°C

The vacuum oven provides a stable thermal environment, specifically maintaining a temperature of 60°C.

This temperature provides the necessary energy to facilitate solvent evaporation without subjecting the active material or the binder to thermal shock.

Ensuring Structural Adhesion

Temperature control works in tandem with pressure to maintain the performance of the binder.

Proper drying ensures the electrode material does not peel off the current collector. A stable thermal profile prevents the detachment of active materials, ensuring the physical durability of the electrode sheet.

Common Pitfalls to Avoid

Incomplete Solvent Removal

If the vacuum pressure is insufficient, solvent molecules may remain trapped deep within the material's pores.

This leads to "fake drying," where the surface appears dry, but internal moisture or solvent remains. This hidden residue will compromise the accuracy of subsequent electrochemical testing results.

The Risk of Rapid Drying

While vacuum drying is efficient, applying excessive heat or sudden pressure changes can damage the coating.

If the drying process is too aggressive, it can disrupt the binder distribution. This results in brittle sheets that may crack or detach, rendering the electrode unusable for practical applications.

Making the Right Choice for Your Goal

To ensure high-quality V-NbOPO4@rGO electrode sheets, tailor your drying process to your specific performance targets:

- If your primary focus is Cycling Stability: Prioritize thorough NMP removal via negative pressure to prevent secondary chemical reactions inside the cell.

- If your primary focus is Mechanical Integrity: Focus on maintaining a stable 60°C temperature to ensure the coating remains dense and adheres firmly to the current collector.

Mastering the balance between vacuum pressure and thermal stability is the single most effective way to guarantee the reliability of your electrode preparation.

Summary Table:

| Parameter | Function | Impact on Electrode Performance |

|---|---|---|

| Vacuum Pressure | Lowers NMP boiling point | Eliminates residual solvent & trapped air bubbles |

| 60°C Temperature | Provides stable thermal energy | Prevents thermal shock & ensures binder adhesion |

| Dual Action | Balanced drying rate | Creates dense, uniform surfaces with no cracking |

| Structural Goal | Material integrity | Prevents detachment from the current collector |

Elevate Your Electrode Research with KINTEK

Precision is non-negotiable in advanced battery material synthesis. KINTEK provides state-of-the-art Vacuum Ovens, Muffle, and Tube furnaces engineered specifically for rigorous lab environments. Backed by expert R&D and manufacturing, our systems ensure the stable temperature control and negative pressure needed to produce flawless V-NbOPO4@rGO sheets.

Whether you require customizable CVD systems or specialized high-temp furnaces, we deliver the reliability your electrochemical testing demands.

Contact KINTEK today to find your ideal thermal solution

Visual Guide

References

- Zhongteng Chen, Zhipeng Sun. Tuning the Electronic Structure of Niobium Oxyphosphate/Reduced Graphene Oxide Composites by Vanadium‐Doping for High‐Performance Na<sup>+</sup> Storage Application. DOI: 10.1002/cnl2.70010

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- Why is MgO used as a hard template for waste PET to carbon conversion? Unlock 3D Porous Structures

- Why is a constant temperature drying oven used at 120°C for 16 hours for NiCuCe catalysts? Optimize Site Dispersion

- How does a laboratory vacuum drying oven contribute to PBI hybrid membranes? Achieve Superior Membrane Density

- What is the function of an electric arc furnace in the preparation of aluminum-silicon model alloys? Expert Insights

- Why Use a Vacuum Drying Oven for Ti3C2 MXene@NiS or Co4S3? Prevent Oxidation and Preserve Catalyst Integrity

- Why is precise temperature control below 1700°C required for beta-SiC? Master Your Cubic Silicon Carbide Synthesis

- What is the necessity of in-situ DRIFTS in formaldehyde oxidation? Uncover Real-Time Catalytic Reaction Mechanisms

- What is the role of a vacuum drying oven in processing MOF precursors? Preserve Integrity for Co-HCC Synthesis