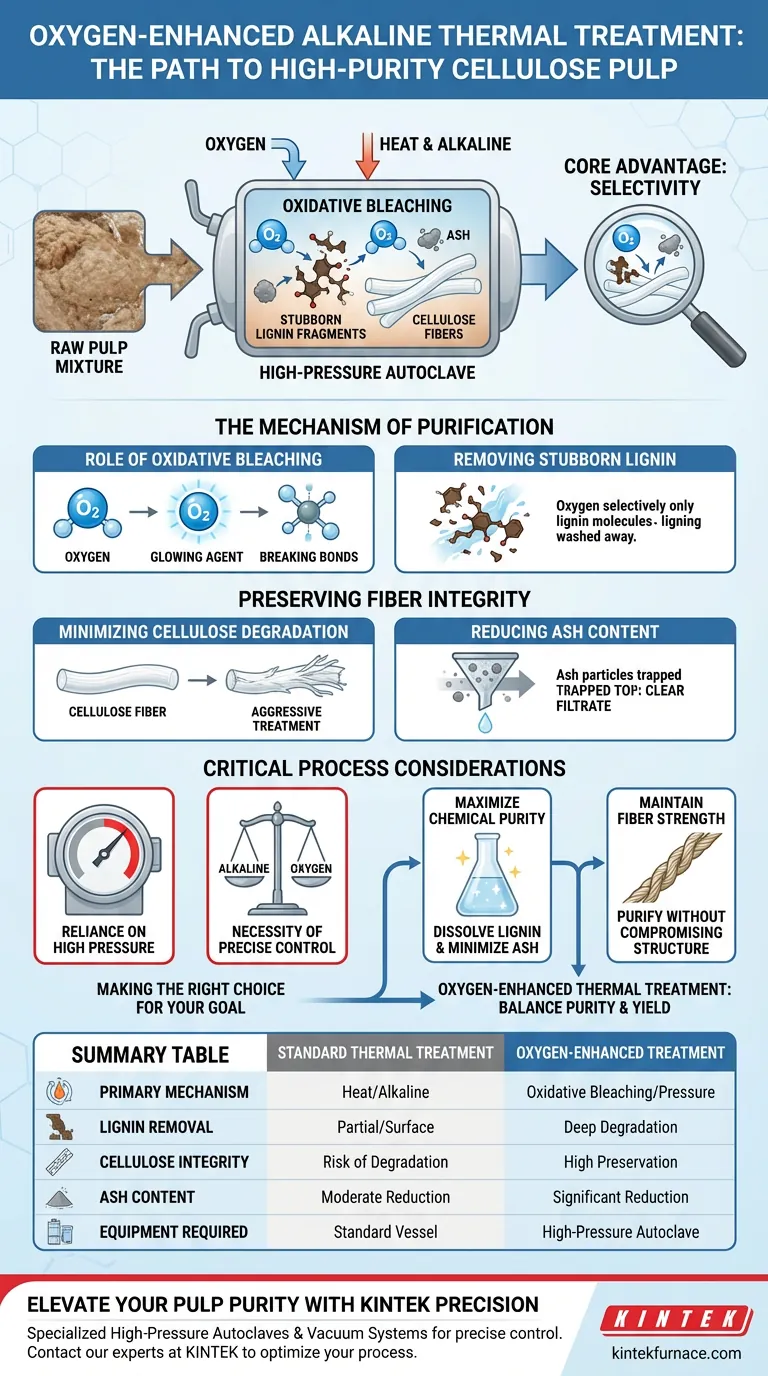

Oxygen-enhanced alkaline thermal treatment functions as a highly selective purification step that separates valuable cellulose from impurities. By introducing oxygen into a high-pressure autoclave during the final stages of processing, the system utilizes oxidative bleaching to degrade stubborn lignin and remove ash, all while preserving the structural integrity of the cellulose fibers.

The core advantage of this method is selectivity. While standard thermal treatments can struggle to remove the final traces of impurities without damaging the product, oxygen enhancement specifically attacks lignin and ash, ensuring high purity without sacrificing cellulose yield.

The Mechanism of Purification

The effectiveness of this process lies in how oxygen modifies the chemical environment within the autoclave.

The Role of Oxidative Bleaching

In a standard alkaline environment, heat alone acts as the primary driver for separation. However, when oxygen is introduced, it initiates a chemical process known as oxidative bleaching.

This reaction transforms the oxygen into an active oxidizing agent. This agent aggressively targets the chemical bonds holding impurities together, facilitating a breakdown that heat alone cannot achieve.

Removing Stubborn Lignin

Lignin is notoriously difficult to remove completely; residual fragments often remain attached to cellulose after initial treatments.

Oxygen-enhanced treatment specifically facilitates the deep degradation of these residual lignin fragments. It dissolves these stubborn contaminants, allowing them to be washed away effectively.

Preserving Fiber Integrity

Achieving purity is only half the battle; the industrial value of cellulose depends on the fiber remaining intact.

Minimizing Cellulose Degradation

Aggressive chemical treatments often damage the cellulose they are meant to purify.

The oxygen-enhanced method is distinct because it minimizes the degradation of the cellulose fibers. It focuses its reactivity on the lignin rather than breaking down the cellulose chains.

Reducing Ash Content

Beyond organic lignin, high-quality pulp must be free of inorganic residues, known as ash.

The oxidative conditions in the high-pressure autoclave contribute to a significant reduction in ash content. This results in a final pulp product that meets the stringent requirements for high-purity applications.

Critical Process Considerations

While highly effective, this method relies on specific operational conditions to succeed.

Reliance on High Pressure

The primary reference notes that this reaction occurs within a high-pressure autoclave.

This pressurized environment is not optional; it is required to force the oxygen to interact effectively with the alkaline solution and the pulp.

The Necessity of Precise Control

The benefits of this process depend on the interaction between the alkaline conditions and the oxygen.

Maintaining the correct balance is essential to ensure the reaction remains selective—targeting the lignin while protecting the cellulose structure.

Making the Right Choice for Your Goal

To determine if this purification stage is appropriate for your processing needs, consider your specific quality targets.

- If your primary focus is maximizing chemical purity: Implement oxygen enhancement to dissolve stubborn lignin fragments and minimize ash content that standard boiling leaves behind.

- If your primary focus is maintaining fiber strength: Rely on the selective nature of oxidative bleaching to purify the pulp without compromising the structural integrity of the cellulose.

Oxygen-enhanced thermal treatment offers the definitive pathway to balancing high purity with high yield.

Summary Table:

| Feature | Standard Thermal Treatment | Oxygen-Enhanced Treatment |

|---|---|---|

| Primary Mechanism | Heat & Alkaline Concentration | Oxidative Bleaching & High Pressure |

| Lignin Removal | Partial / Surface Level | Deep Degradation of Stubborn Fragments |

| Cellulose Integrity | Risk of Degradation | High Preservation (Selective Action) |

| Ash Content | Moderate Reduction | Significant Reduction |

| Equipment Required | Standard Reaction Vessel | High-Pressure Autoclave |

Elevate Your Pulp Purity with KINTEK Precision

High-purity cellulose production demands the perfect balance of pressure, temperature, and chemical selectivity. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized High-Pressure Autoclaves and Vacuum Systems designed to handle the rigorous demands of oxygen-enhanced alkaline treatments. Whether you need standard lab high-temp furnaces or fully customizable CVD and rotary systems, our technology ensures precise control to protect your fiber integrity while eliminating stubborn impurities.

Ready to optimize your purification process? Contact our experts today to discover how KINTEK’s customizable thermal solutions can maximize your yield and chemical purity.

Visual Guide

References

- Multi-step pre-treatment of rice husk for fractionation of components including silica. DOI: 10.3389/fchem.2025.1538797

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the advantages of activated carbon in tantalum processing? Enhance Your Carburization Efficiency Today

- What are the primary purposes of using high-purity argon flow during the pyrolysis of CMS membranes? Achieve High-Purity Results

- How does the catalytic steam reforming system convert refinery waste gas into syngas for SOFC? Maximize Waste Energy

- What is the function of a high-temperature sintering furnace in ceramic membrane production? Engineered Performance

- What role does a releasing agent play during the assembly process of titanium-steel composite plates?

- Why are acid washing and vacuum drying ovens required after carbon activation? Unlock Maximum Purity and Pore Access

- What is the primary function of an industrial drying oven for GBC? Achieving Material Standardization and Quality

- What advantages does a vacuum drying oven offer? Superior Chemical Stability & Efficient Dehydration